Riser hammer test device

A test device and riser removal technology, applied in the field of foundry machinery, can solve the problem of enlarged diameter of the bottom of the lead post

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

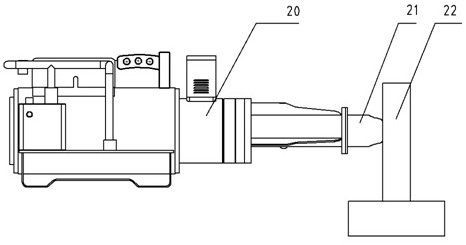

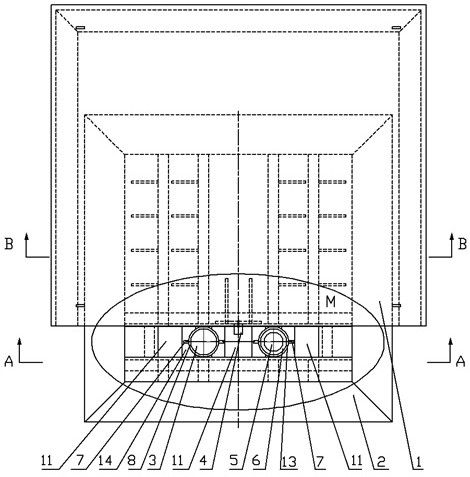

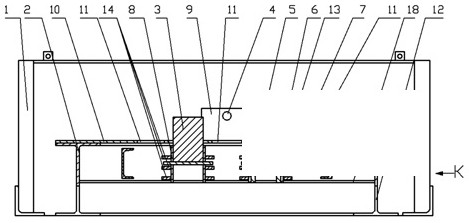

[0023] Such as figure 2 Shown, a kind of riser hammer test device, it comprises base 2, and base 2 is made up of several beams 19 and longitudinal beam 17 welded together, also comprises two sample sleeves welded on the beam 19, sample cover There are three pairs of clamping plates 14 arranged horizontally on the outer side of the tube from top to bottom to weld the sample sleeve and beam 19 together. The clamping plates 14 are provided with arc-shaped grooves that match the shape of the outer wall of the sample sleeve; the sample sleeve The upper plane of the cylinder is flush with the upper plane of the base 2, and the sample sleeve includes a fatigue sample sleeve 8 and a failure sample sleeve 13, and an adjustment sleeve 6 is placed in the failure sample sleeve 13, and the outer diameter of the adjustment sleeve 6 is the same as the failure specimen sleeve 13. The inner diameter of the sample sleeve 13 is the same, the inner diameter of the adjusting sleeve 6 is consistent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com