Fixed-point collector for sludge sample in fermentation tank and sampling method

A fermenter and collector technology, which is applied to the fixed-point collector and sampling field of sludge samples in the fermenter, can solve the problems of single location, difference in fermentation level, unrefined micro-environmental analysis, etc., and achieve variable sampling and analysis positions, increased The effect of large sample volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

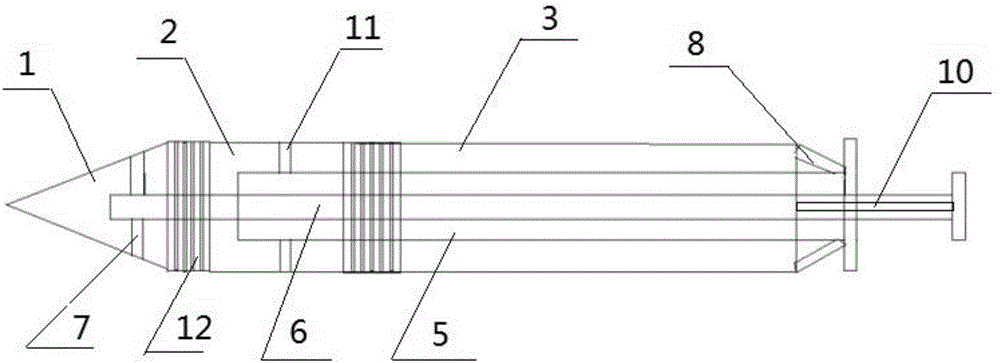

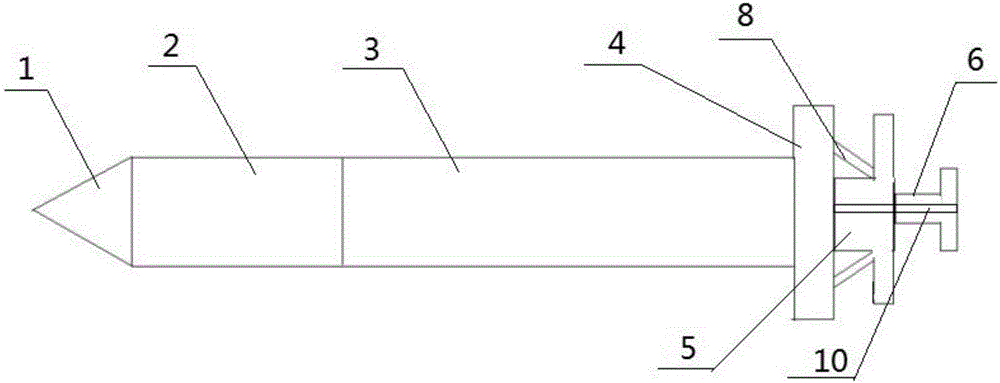

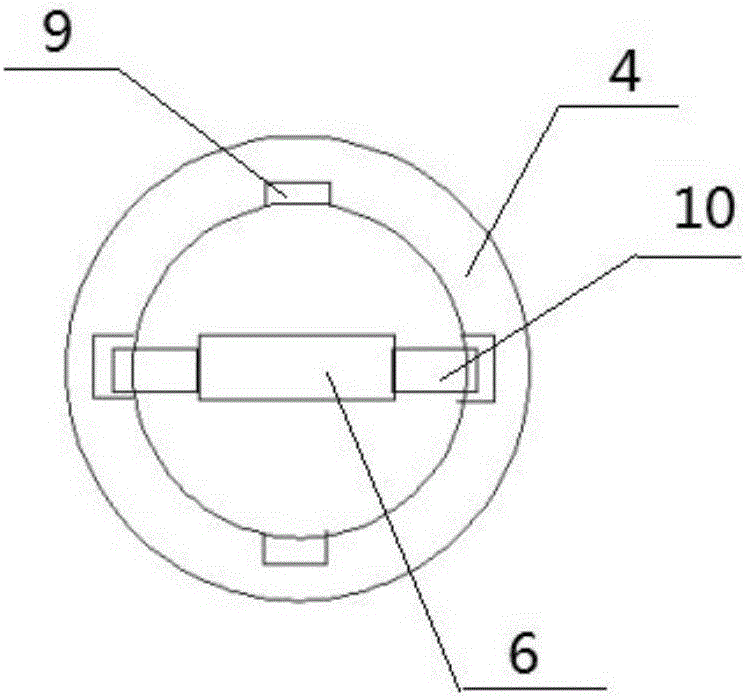

[0018] A fixed-point collector for sludge samples in a fermenter, comprising a tip sampling tube 1, the tip sampling tube is connected to an extension tube 2, the extension tube is connected to an arm tube 3, and the tip sampling tube is equipped with a first The control rod fixing bar 7, the inside of the extension tube is equipped with a second control rod fixing bar 11, the first control rod fixing bar is fixedly connected to the tip sampling tube control rod 6, and the bottom of the tip sampling tube control rod Two second card holders 10 are installed at both ends, and the second control rod fixing strip is fixedly connected to the extension tube control rod 5, and two first card holders 8 are installed at both ends of the bottom of the extension tube control rod, so The extension tube control rod is hollow tubular, and the tip sampling tube control rod passes through the extension tube control rod and is inserted into the tip sampling tube.

[0019] The bottom of the out...

specific Embodiment approach 2

[0021] The sampling method of the sludge sample fixed-point collector in the fermentation tank of the present invention, the sampling total amount is 50ml, comprises the steps:

[0022] Step 1. When sampling, hold the top of the fixed-point collector for sludge samples in the fermentation tank, insert the tip sampling tube of the tip sampler from the mouth of the fermentation tank, and control the insertion position as needed;

[0023] Step 2. Take a small amount of samples, insert and rotate the wall tube, unscrew the thread, slowly push out the tip sampling tube control rod, tilt the device slightly left and right, then slowly withdraw the tip sampling tube control rod, and lock the wall tube after returning , Pull out the fixed-point collector for sludge samples in the fermenter from the fermenter;

[0024] Step 3. Unscrew the thread between the tip sampling tube and the wall tube, push out the tip sampling tube, pour out or scrape out the sample taken in step 2, and comple...

specific Embodiment approach 3

[0026] The sampling method of the sludge sample fixed-point collector in the fermentation tank of the present invention, the sampling total amount is 200ml, comprises the steps:

[0027] Step 1. Fix the extension tube to the tip sampling tube;

[0028] Step 2. When sampling, hold the top of the fixed-point collector for sludge samples in the fermentation tank, insert the tip of the tip sampler from the mouth of the fermentation tank, and control the insertion position as needed;

[0029] Step 3. Take a large number of samples. After inserting, rotate the wall tube, unscrew the thread, and slowly push out the control rod of the tip sampling tube and the control rod of the extension tube, tilt the device slightly left and right, and then slowly withdraw the control rod of the tip sampling tube and the extension tube After returning to the position, lock the wall pipe, and pull out the fixed-point collector for sludge samples in the fermentation tank;

[0030] Step 4. Unscrew th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap