Three-coordinate measurement point operation and control system based on real-time measurement point track

A control system, operation control technology, applied in general control system, control/regulation system, adaptive control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

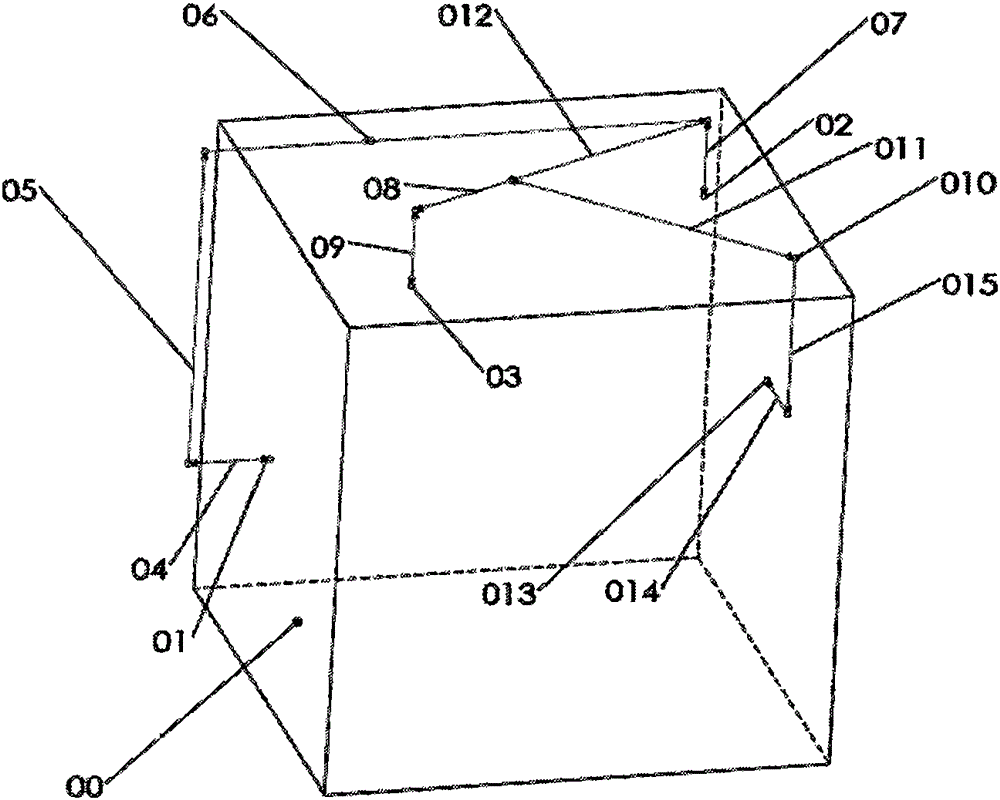

[0011] See attached figure 1 , 2 , a three-coordinate measuring point operation control system based on real-time measuring point trajectory, comprising a three-coordinate measuring machine, a control system electrically connected with the three-coordinate measuring machine, an operation box electrically connected with the control system, and an operation box With "select measurement key" and "repeat measurement key", when using the operation box to control the three-coordinate measuring machine to perform measurement operations, the control method adopted by the control system is: the control system records the track of the measuring points of the three-coordinate measuring machine in real time and forms a measurement point track file, the control system records the last measuring point track of the three-coordinate measuring machine in real time. point as the target measuring point, and control the three-coordinate measuring machine to automatically complete the measuring p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com