A catalyst component for ethylene polymerization, its preparation method and application

A technology for ethylene polymerization and catalysts, which is applied in the field of supported chromium-based catalyst components, and can solve problems such as undisclosed chromium-based catalyst systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

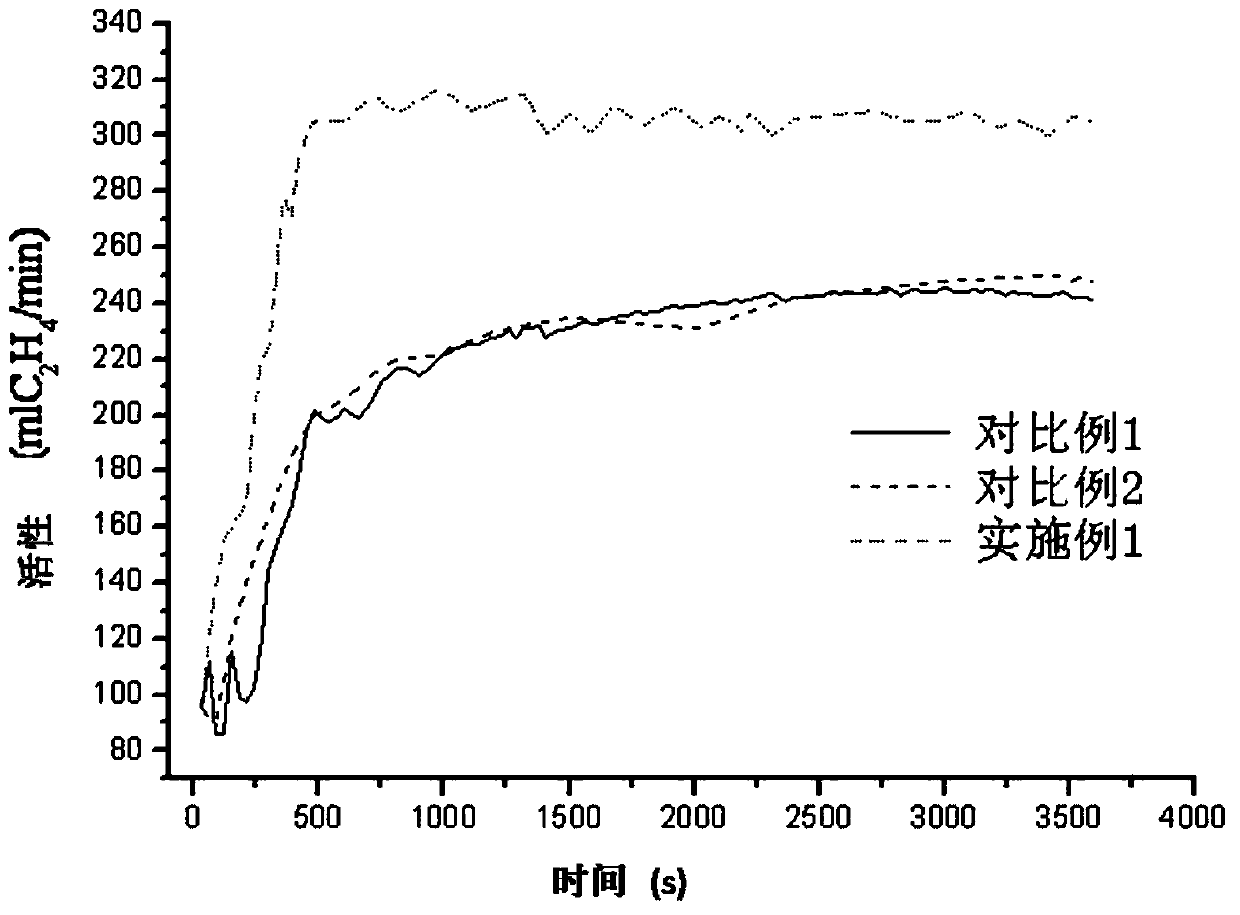

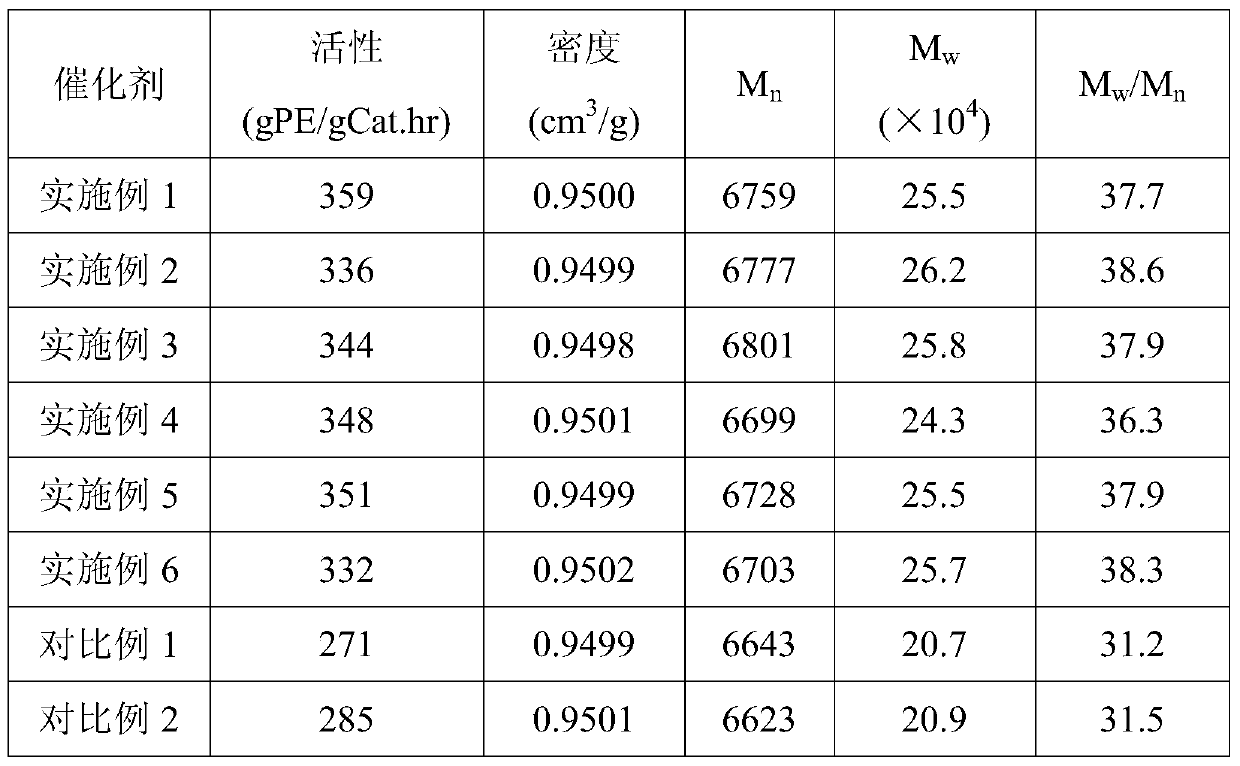

Embodiment 1

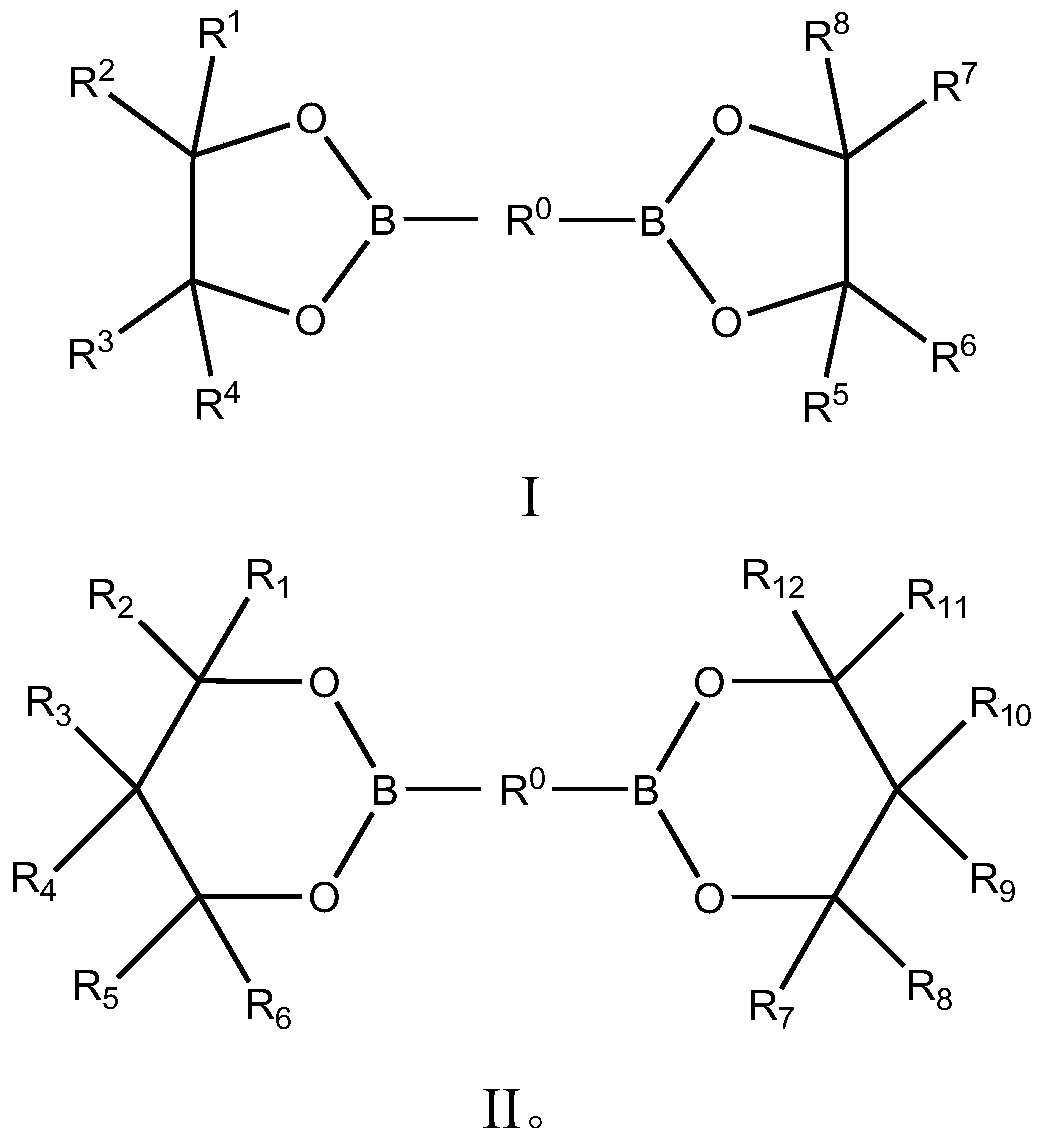

[0047] Take 10g silica gel (W.R.Grece&Co.–Com 955, the pore volume is about 1.1-1.8cm 3 / g, the surface area is about 245-375m 2 / g) Dry at 200°C for 4 hours under nitrogen fluidization. Add 0.5 g of bis(triphenylsilyl) chromate to the reactor fully replaced with anhydrous and oxygen-free nitrogen, and then add 300 ml of hexane, and stir at room temperature to completely dissolve the solid to form a solution. Add 10g of dried silica gel to the above solution. After stirring, add 2ml (1.3M) diethyl aluminum ethoxide in hexane. After stirring for 1 hour at room temperature, add 2.4mmol of 4,4'-di (4,4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)biphenyl was stirred at room temperature for 1 hour and the solvent was removed to obtain a chromium-containing catalyst component. The polymerization evaluation results of the catalyst are shown in Table 1.

Embodiment 2

[0049] Take 10g silica gel (W.R.Grece&Co.–Com 955, the pore volume is about 1.1-1.8cm 3 / g, the surface area is about 245-375m 2 / g) Dry at 200°C for 4 hours under nitrogen fluidization. Add 0.5 g of bis(triphenylsilyl) chromate to the reactor fully replaced with anhydrous and oxygen-free nitrogen, and then add 300 ml of hexane, and stir at room temperature to completely dissolve the solid to form a solution. Add 10g of dried silica gel to the above solution. After stirring, add 2.4mmol of 4,4'-bis(4,4,5,5-tetramethyl-1,3,2-dioxole Alk-2-yl) biphenyl, after stirring at room temperature for 1 hour, add 2ml (1.3M) diethyl aluminum ethoxide in hexane solution, after stirring at room temperature for 1 hour, remove the solvent to obtain a chromium-containing catalyst component. The polymerization evaluation results of the catalyst are shown in Table 1.

Embodiment 3

[0051] Take 10g silica gel (W.R.Grece&Co.–Com 955, the pore volume is about 1.1-1.8cm 3 / g, the surface area is about 245-375m 2 / g) Dry at 200°C for 4 hours under nitrogen fluidization. Add 0.5 g of bis(triphenylsilyl) chromate to the reactor fully replaced with anhydrous and oxygen-free nitrogen, and then add 300 ml of hexane, and stir at room temperature to completely dissolve the solid to form a solution. The dried 10g silica gel was added to the above solution, and after stirring, 2ml (1.3M) hexane solution of diethyl aluminum ethoxide and 2.4mmol of 4,4'-bis(4,4,5,5 -Tetramethyl-1,3,2-dioxaborolan-2-yl)biphenyl, stirred at room temperature for 2 hours and then removed the solvent to obtain a chromium-containing catalyst component. The polymerization evaluation results of the catalyst are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com