Quaternary ammonium type paper making additive and method for preparing same

A paper-making auxiliary, quaternary ammonium-type technology, applied in the field of polymer chemical auxiliary preparation, can solve the problems of paper-making performance decline, high use cost, difficult to waste fiber reinforcement and retention, etc., to achieve increased polymerization rate, Fast reaction speed, avoiding the effect of easy cross-linking of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

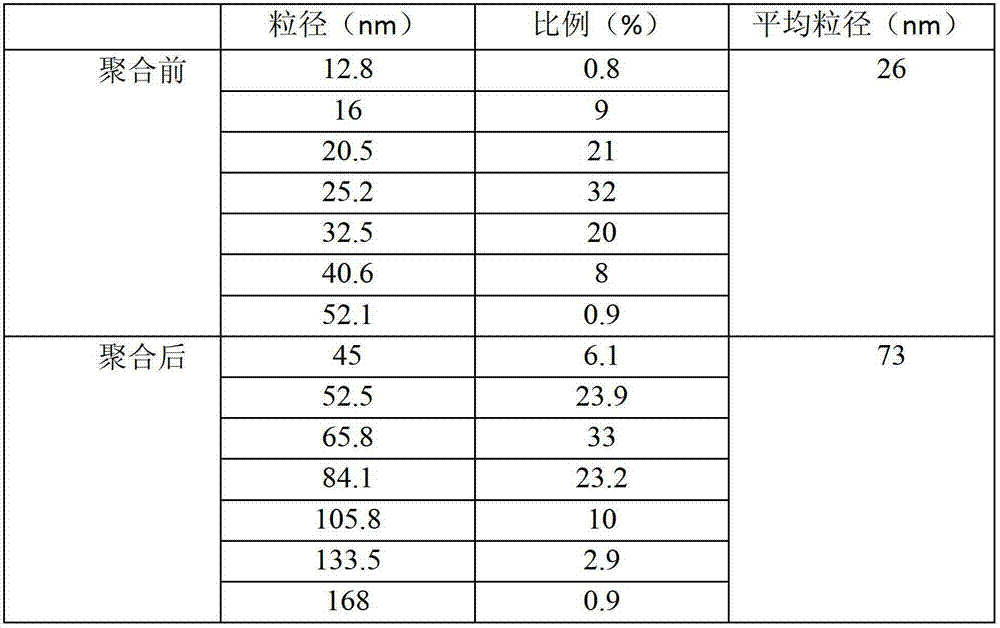

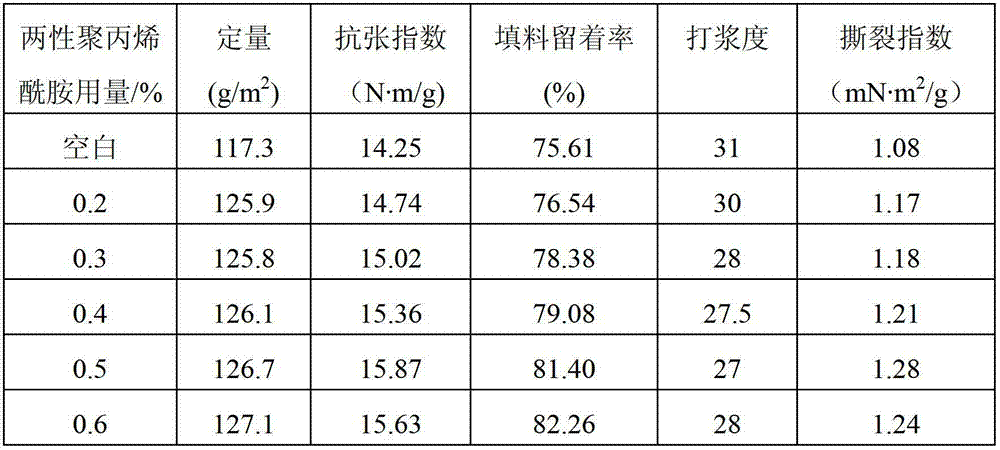

Embodiment 1

[0027] Add 32.5g of Span80, 21.5g of Tween60 and 150g of cyclohexane into the reaction flask equipped with a stirrer, reflux condenser, nitrogen pipe and thermometer, place in a constant temperature water bath at 30°C, stir and emulsify for 30min to obtain oily phase. In a beaker, DMC, AM and AA three kinds of monomers are configured into 100g aqueous solution according to the molar ratio of DMC:AM:AA=1.5:7:1.5, the mass concentration is 50%, and the pH is adjusted to 5, and then added to the above solution Add 0.2 g of sodium bisulfite to obtain a mixed solution of ternary monomers. Then slowly and evenly drop the above-mentioned ternary monomer mixed solution into the oil phase of the reaction bottle, and control the rate so that the dropwise addition is completed within 10 minutes. About 10 minutes after the ternary monomer mixed solution was added dropwise, 10ml of the oxidant solution (containing 0.4g ammonium persulfate) was added dropwise at a constant speed, and nitro...

Embodiment 2

[0038] Add 21.5g of Span80, 21.5g of Tween60 and 175g of cyclohexane into a reaction flask equipped with a stirrer, reflux condenser, nitrogen pipe and thermometer, place in a constant temperature water bath at 40°C, stir and emulsify for 35min to obtain oily phase. In a beaker, DMC, AM and AA three monomers are prepared according to the molar ratio of DMC: AM: AA = 1.5: 7: 1.5 to form 100g aqueous solution with a mass concentration of 40%, and adjust the pH to 6, and then add to the above solution Add 0.3 g of sodium bisulfite to obtain a mixed solution of ternary monomers. Then slowly and evenly drop the above-mentioned ternary monomer mixed solution into the oil phase of the reaction bottle, and control the rate so that the dropwise addition is completed within 15 minutes. About 10 minutes after the ternary monomer mixed solution was added dropwise, 10ml of the oxidant solution (containing 0.6g of ammonium persulfate) was added dropwise at a constant speed, and nitrogen ga...

Embodiment 3

[0044] Add 19.5g of Span80, 34.5g of Tween60 and 200g of cyclohexane into a reaction flask equipped with a stirrer, reflux condenser, nitrogen pipe and thermometer, place in a constant temperature water bath at 50°C, stir and emulsify for 40min to obtain oily phase. In a beaker, DMC, AM and AA three kinds of monomers are configured into 100g aqueous solution according to the molar ratio of DMC:AM:AA=1.5:7:1.5, the mass concentration is 30%, and the pH is adjusted to 7, and then added to the above solution Add 0.4 g of sodium bisulfite to obtain a mixed solution of ternary monomers. Then slowly and evenly drop the above-mentioned ternary monomer mixed solution into the oil phase of the reaction bottle, and control the rate so that the dropwise addition is completed within 20 minutes. About 15 minutes after the ternary monomer mixed solution was added dropwise, 10ml of the oxidant solution (containing 0.8g of ammonium persulfate) was added dropwise at a constant speed, and nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com