A kind of oxygen avoidance device for free radical polymerization reaction

A polymerization reaction and free radical technology, applied in chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc., can solve the problems of insufficient deoxygenation and complicated operation, etc. Achieve the effect of low cost, simple operation and shortened induction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

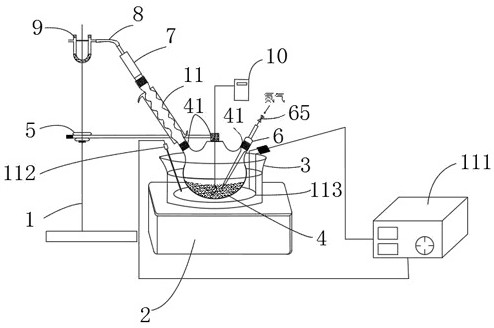

[0027] Embodiment 1, reference figure 1 , Figure 3 to Figure 5

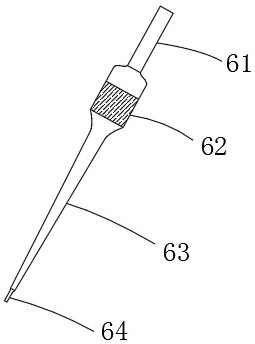

[0028] An oxygen avoidance device for free radical polymerization, comprising a magnetic stirrer 2 and an iron stand 1 arranged on one side of the magnetic stirrer, a constant temperature oil bath 3 is placed on the magnetic stirrer, and the constant temperature oil The bathing pot is provided with a reaction vessel 4 whose mouth is connected to the iron frame platform through the fixing clip 5. The reaction liquid is housed in the reaction vessel and is provided with a magnetic stirrer for stirring. The top of the reaction vessel is provided with three The opening 41 of the mouth is preferably a three-necked flask. The opening on the rightmost side of the reaction vessel is connected with a glass capillary 6 externally connected to an inert gas source. The other end of the glass capillary extends into the reaction vessel through the opening and the bottom is completely immersed in the reaction liquid to provi...

Embodiment 2

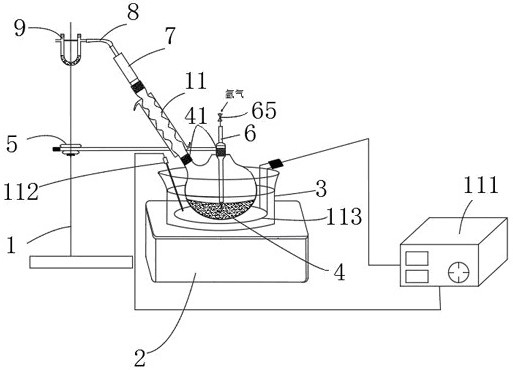

[0044] Embodiment 2, refer to Figure 2 to Figure 5

[0045] An oxygen avoidance device for free radical polymerization, comprising a magnetic stirrer 2 and an iron stand 1 arranged on one side of the magnetic stirrer, a constant temperature oil bath 3 is placed on the magnetic stirrer, and the constant temperature oil The bathing pot is provided with a reaction vessel 4 whose mouth is connected to the iron frame platform through the fixing clip 5. The reaction liquid is housed in the reaction vessel and is provided with a magnetic stirrer for stirring. The top of the reaction vessel is provided with two standard The opening 41 of the ground mouth is preferably a two-necked flask. The opening on the right side of the reaction vessel is connected with a glass capillary 6 externally connected to an inert gas source. The other end of the glass capillary extends into the reaction vessel through the opening and the bottom is completely immersed in the reaction liquid. An inert ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com