Robot quick-changing gripper for grinding

A robot and gripper technology, applied in the field of robot quick-change grippers, can solve the problems of difficulty in batch processing, error-prone, high randomness, etc., and achieve the effects of enhanced torsional strength, easy rapid replacement, and low positioning deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the following detailed description is not considered to limit the present invention.

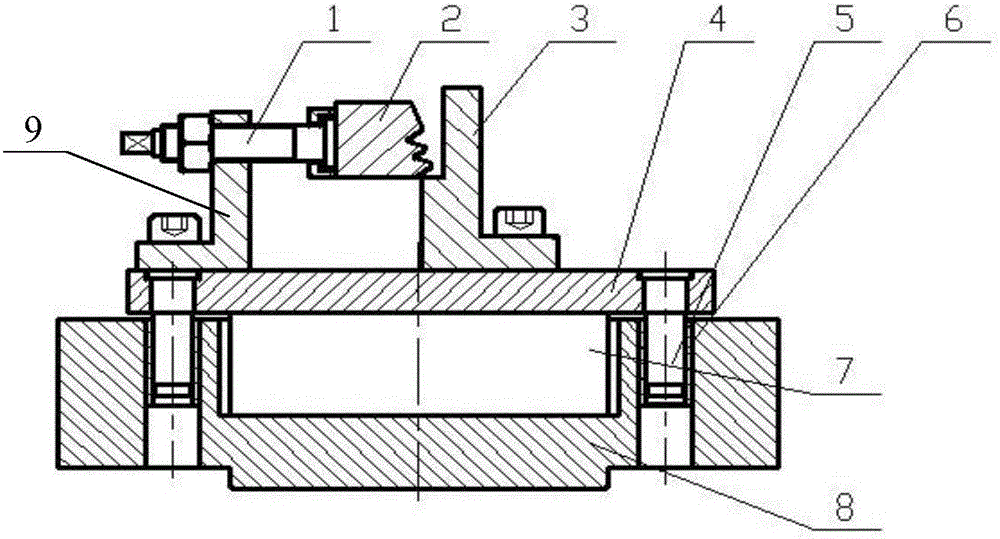

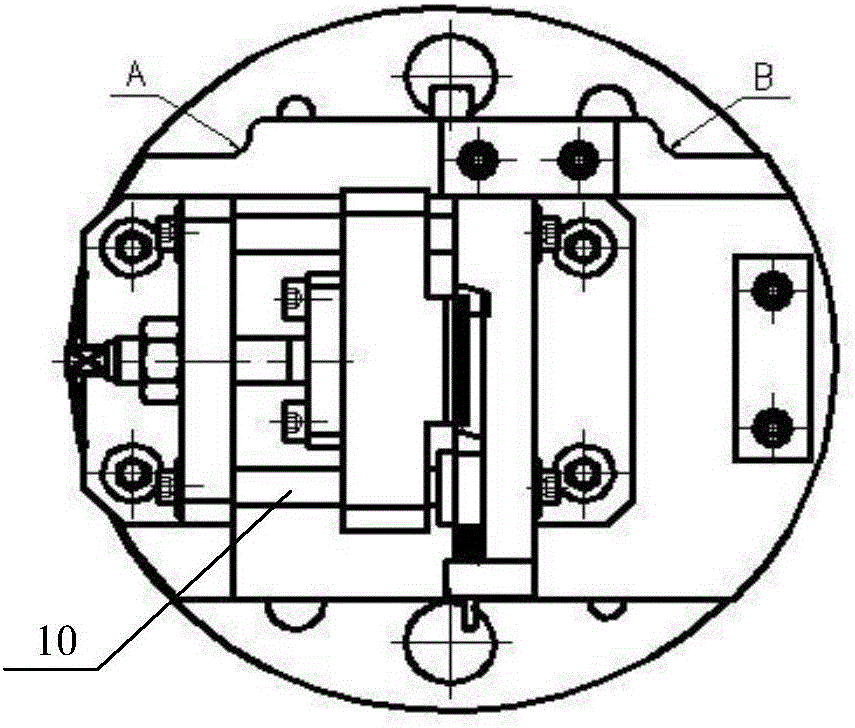

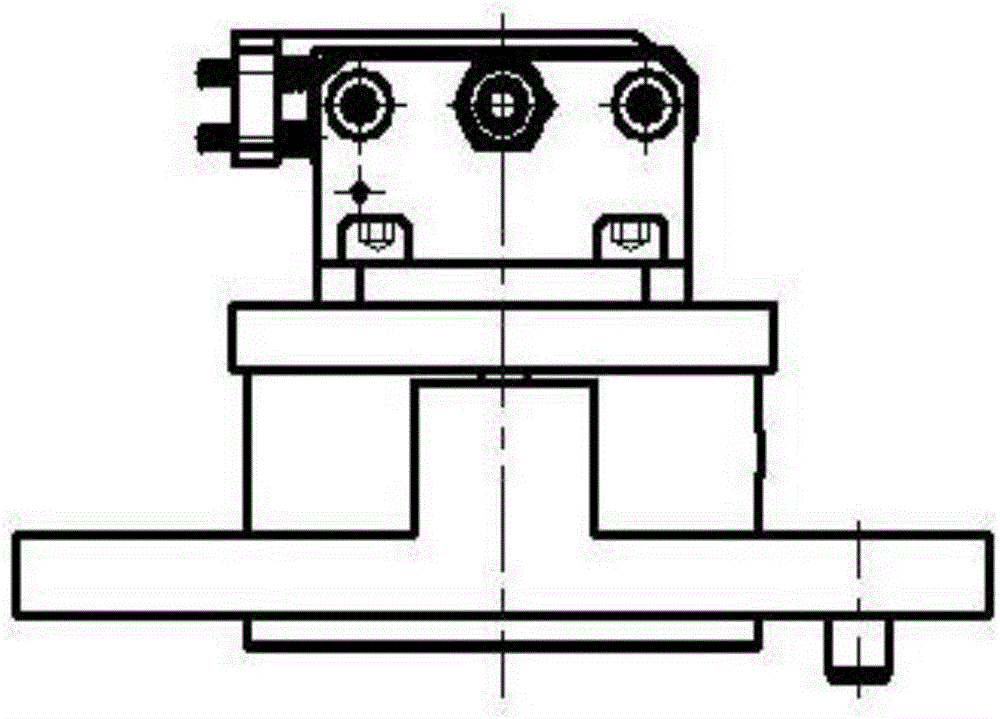

[0023] in, figure 1 It is a front view sectional structural schematic diagram of the quick-change gripper in a preferred solution of the present invention. figure 2 for figure 1 Schematic diagram of the top view structure. image 3 for figure 1 Schematic diagram of the left view structure.

[0024] from Figure 1-3 It can be seen from the figure that the quick-change gripper of the robot is composed of a robot connector 8, an electromagnet 7, a base plate 4, a set bolt 1, a pressing block 2, a positioning block I 3, a positioning block II 9, a copper sleeve 6, and a positioning pin 5 And two fixed pins 10 are formed. Wherein, the set bolt 1, the pressing block 2, the positioning block I 3, the positioning block II 9 and the fixing pin 10 form a guiding mechanism. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com