A sealing structure, an oil cylinder and a wind generator

A sealing structure and sealing ring technology, applied in mechanical equipment, fluid pressure actuating devices, etc., can solve the problems of short service life, high failure rate of wind turbines, easy oil leakage, etc., and achieve long service life and reduce temperature rise. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

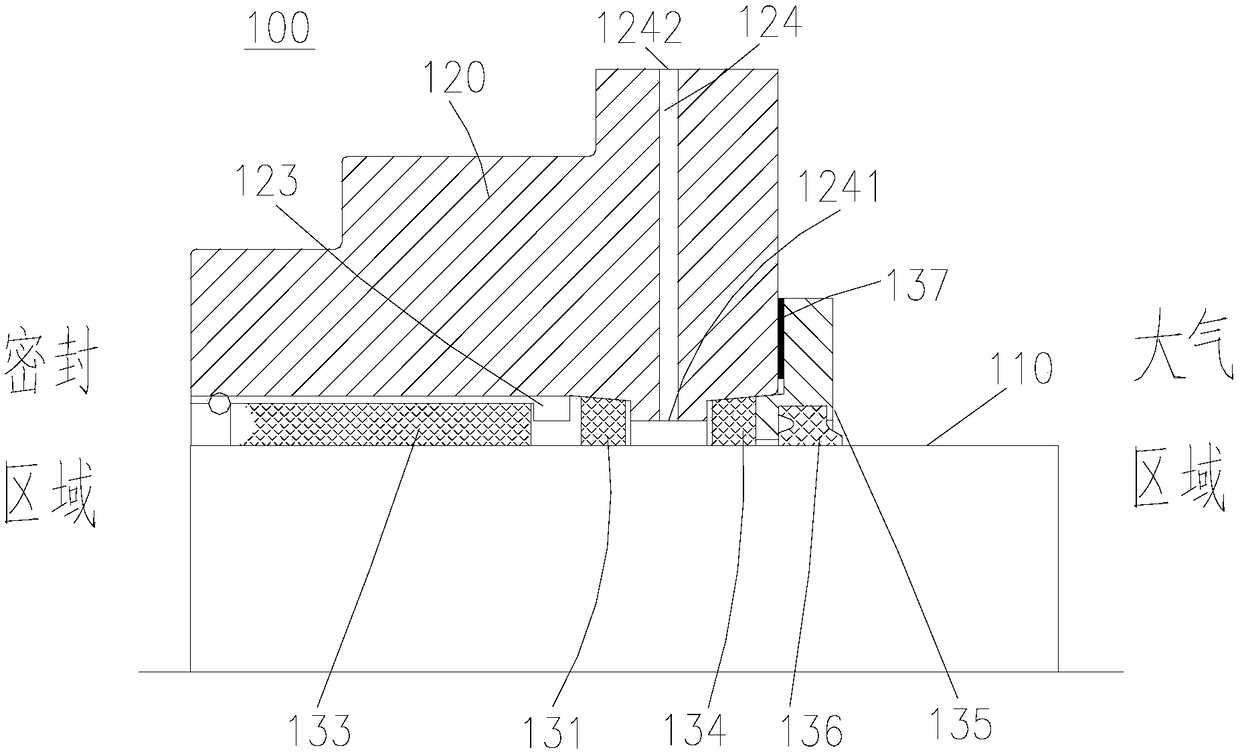

[0076] This embodiment provides an oil cylinder 200, please refer to figure 1 and Figure 11 , the oil cylinder 200 includes a cylinder block 210, a piston rod 110 and a guide sleeve 120, the guide sleeve 120 is fixed and sealed with the cylinder block 210, the piston rod 110 and the guide sleeve 120 form a piston rod assembly, and the sealing structure 100 is used for the piston rod 110 and the guide The seal of the sleeve 120 is connected. The inner side of the oil cylinder 200 is the sealing area, and the outer side of the oil cylinder 200 is the atmospheric area.

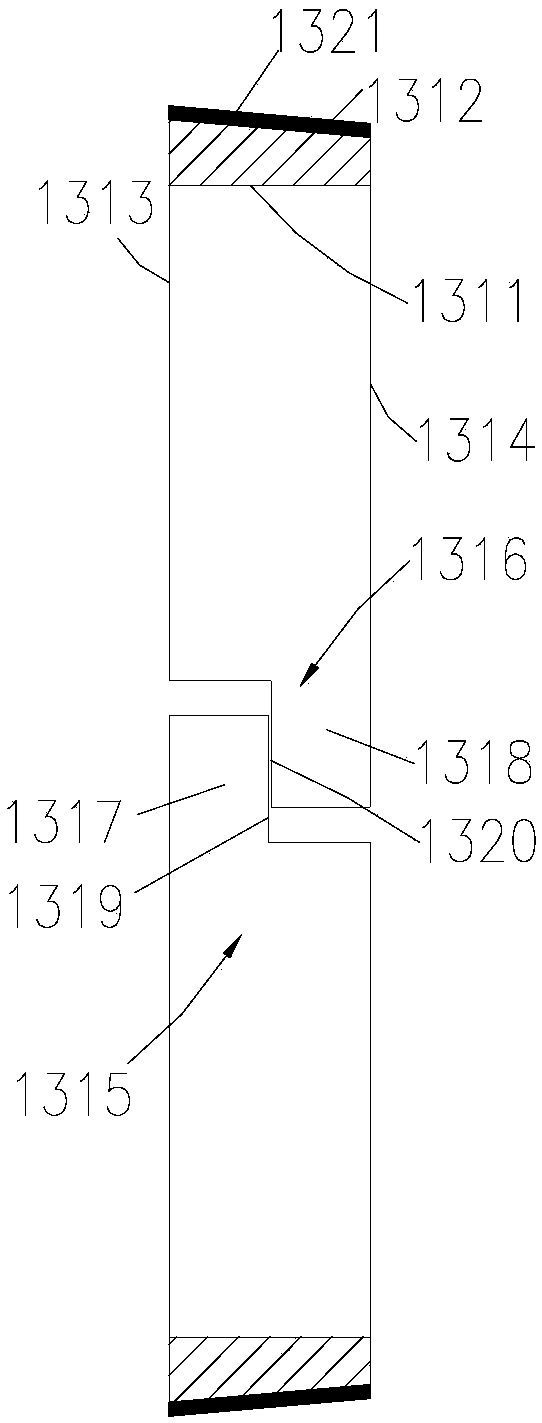

[0077] like figure 1 As shown, the sealing structure 100 includes a support ring 133 , a first sealing ring 131 , a second sealing ring 134 and a gland 135 .

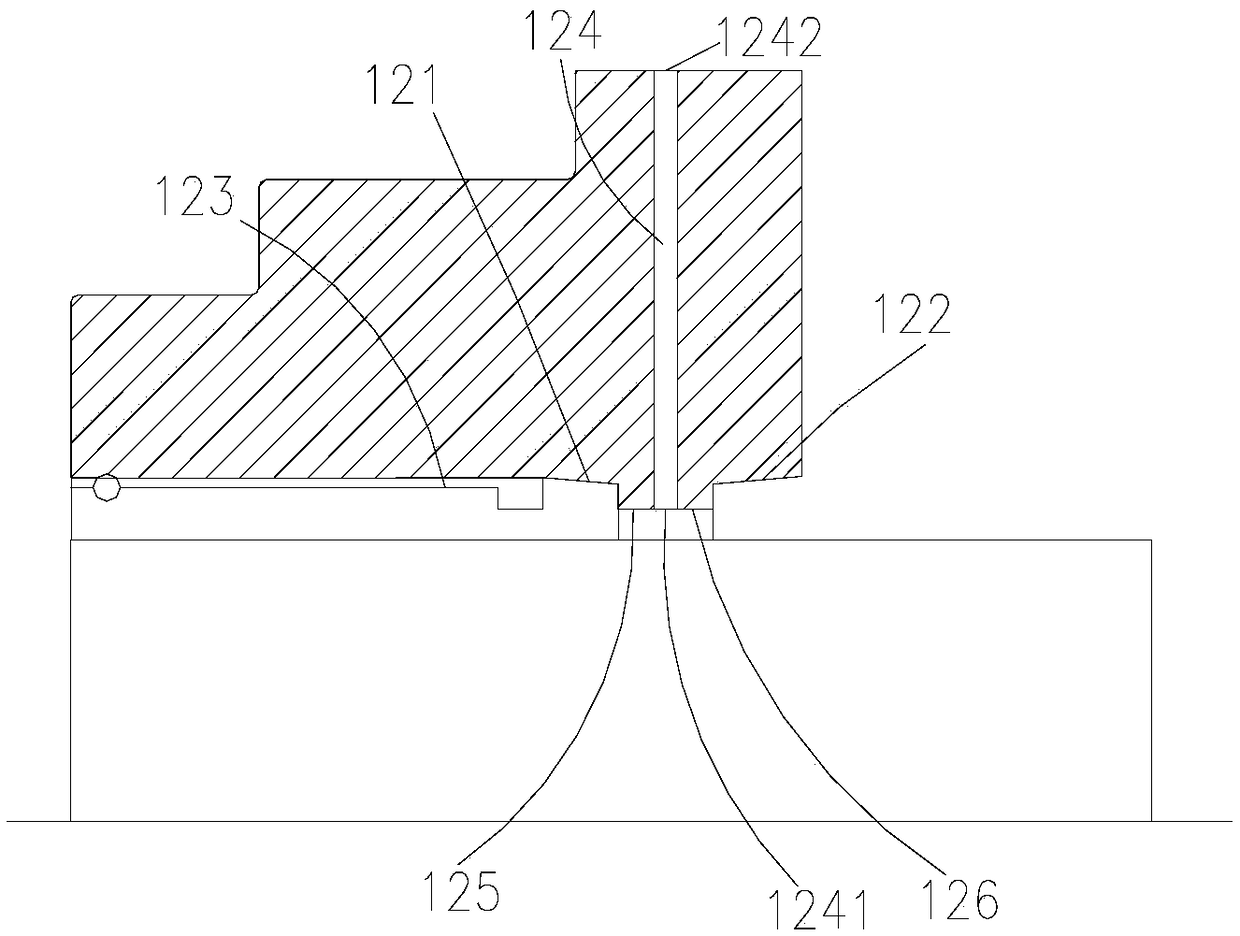

[0078] like figure 1 and figure 2 As shown, the guide sleeve 120 is a revolving structure, its outer side is a stepped structure, and its inner side is distributed along its axis direction with an annular first mating surface 121 and a second mating...

Embodiment 2

[0097] This embodiment provides a wind power generator (not shown in the figure), and the wind power generator applies the oil cylinder 200 in the first embodiment. The wind turbine using this oil cylinder 200 has a good sealing effect during operation. The wear and tear mileage of the oil cylinder 200 can reach tens of thousands of kilometers. It can be taken away quickly and improve the service life of the wind turbine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com