A vertical on-site torque calibration device based on the force principle of the reducer

A technology of calibration device and force application device, applied in the direction of force/torque/power measuring instrument calibration/test, measuring device, instrument, etc., can solve the problems of inapplicable on-site detection, low measurement accuracy, long time, etc., to achieve High torque on-site calibration, long solution time and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

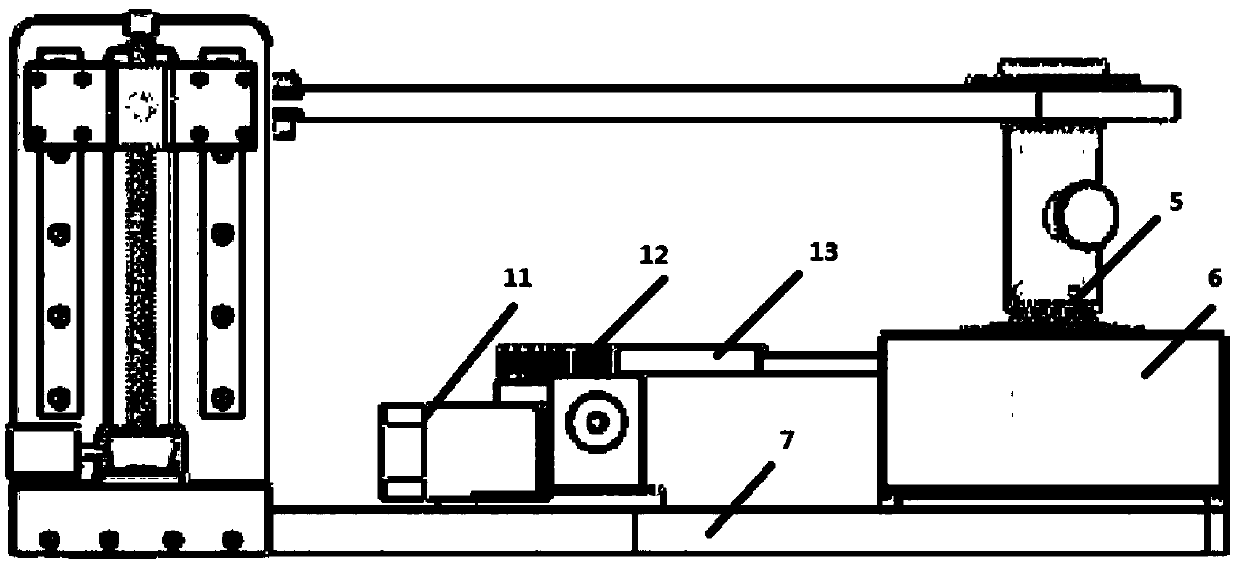

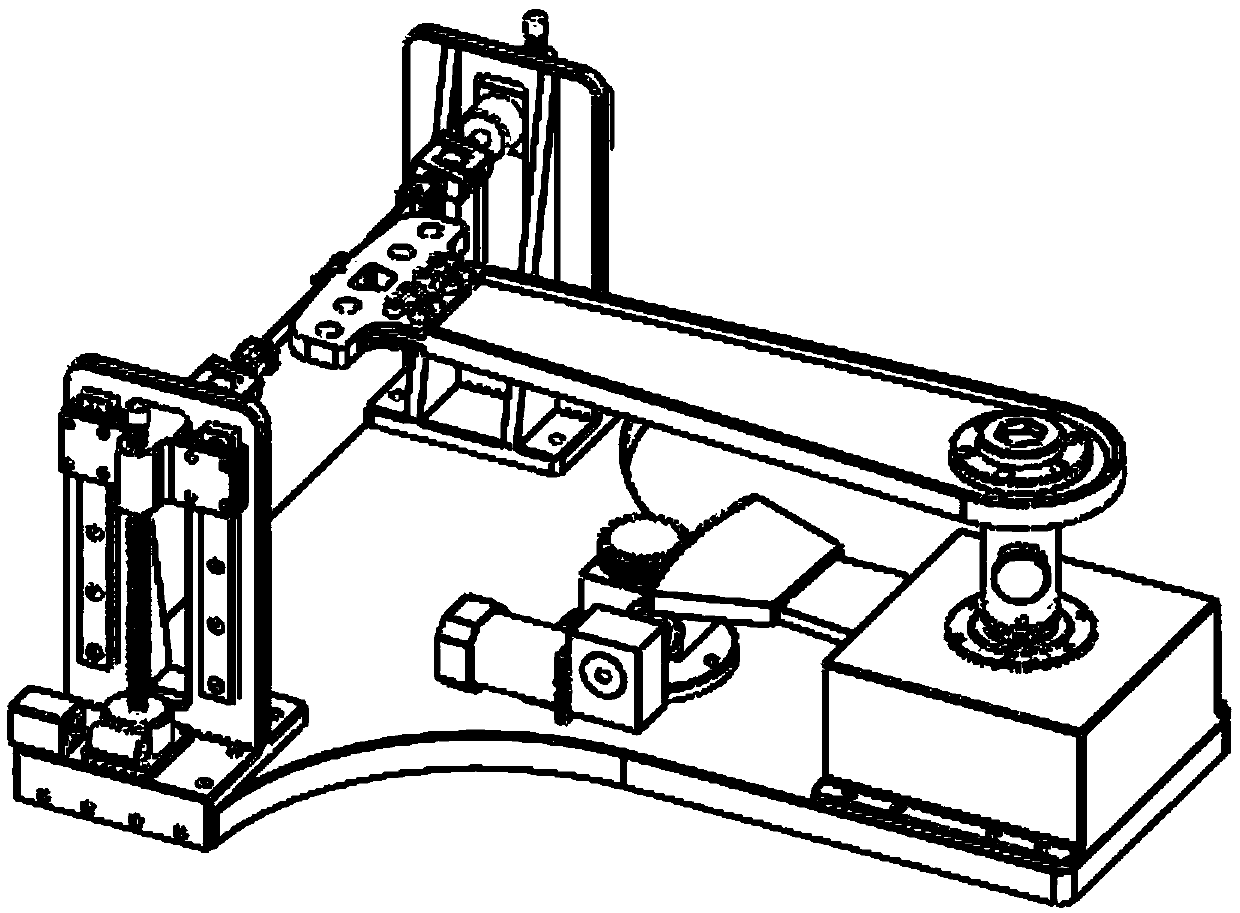

[0021] A vertical on-site torque calibration device based on the force applied principle of the reducer, such as image 3 As shown, it includes a movable workbench, a base 7, a first electric screw lifting table 1 and a second electric screw lifting table 2, a standard lever 4, a pressing piece 3, a first standard S-type sensor 9 and a second standard S type sensor 10, the sensor to be tested 5, the anti-lateral force device 6, and the reducer device that the motor 11, the circular gear 12 and the sector gear 13 constitute.

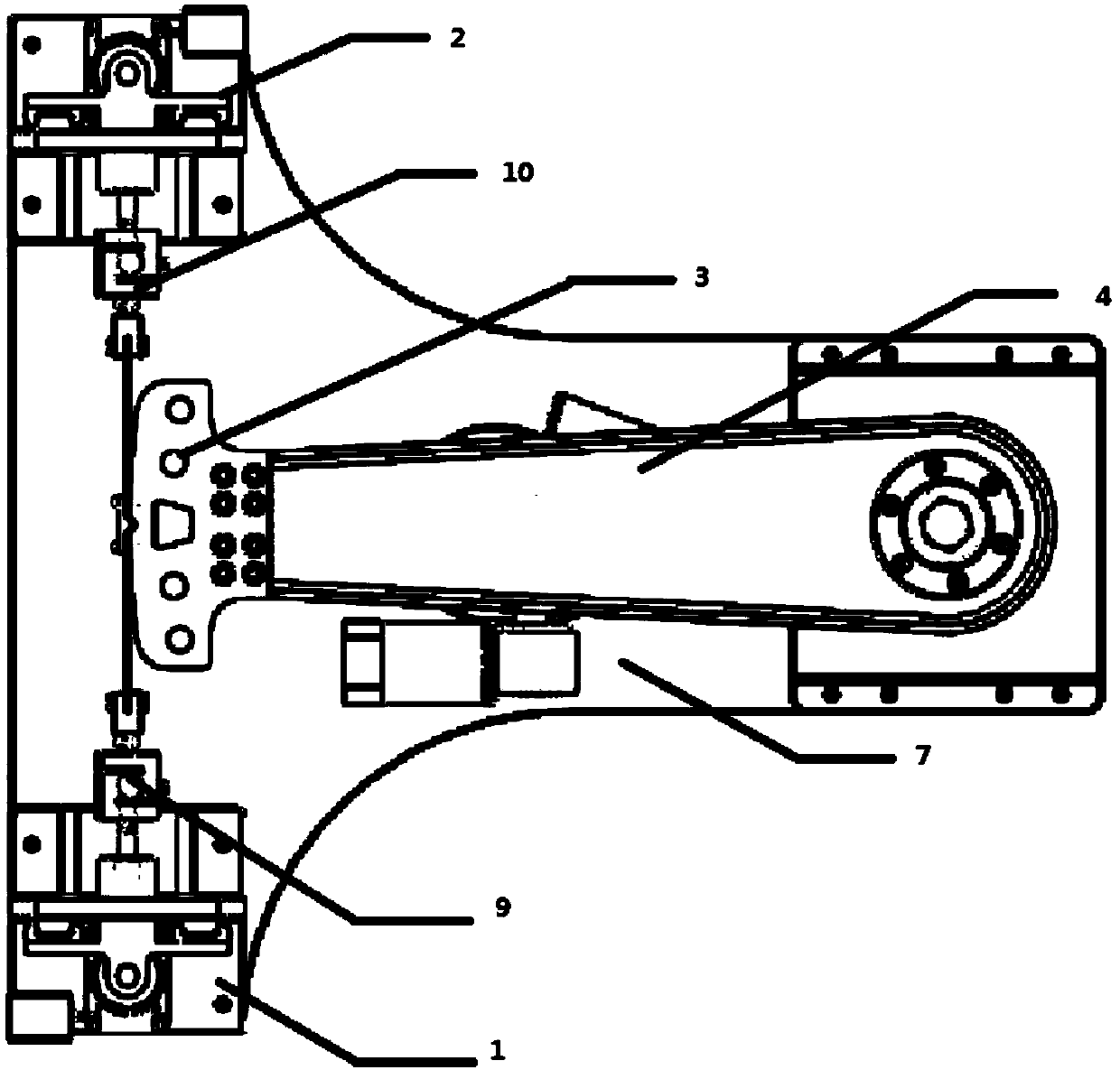

[0022] like figure 2 As shown, the first electric screw lifting platform 1 and the second electric screw lifting platform 2 are symmetrically arranged on the base 7; the standard S-type sensor is connected to the pressing piece 3 by a steel wire; the pressing piece 3 is fixed on the standard lever 4 One end; the pressing piece 3 and the standard lever 4 are symmetrical along the center line as a whole; the other end of the standard lever 4 has a through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com