A method and device for controlling the movement of a robot following a conveyor belt

A conveyor belt and robot technology, applied in the direction of feedback control, etc., can solve the problems of conveyor belt and robot staggered operation, unable to meet multi-point follow-up, etc., to achieve the effect of shortening process operation time, small range limitation, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

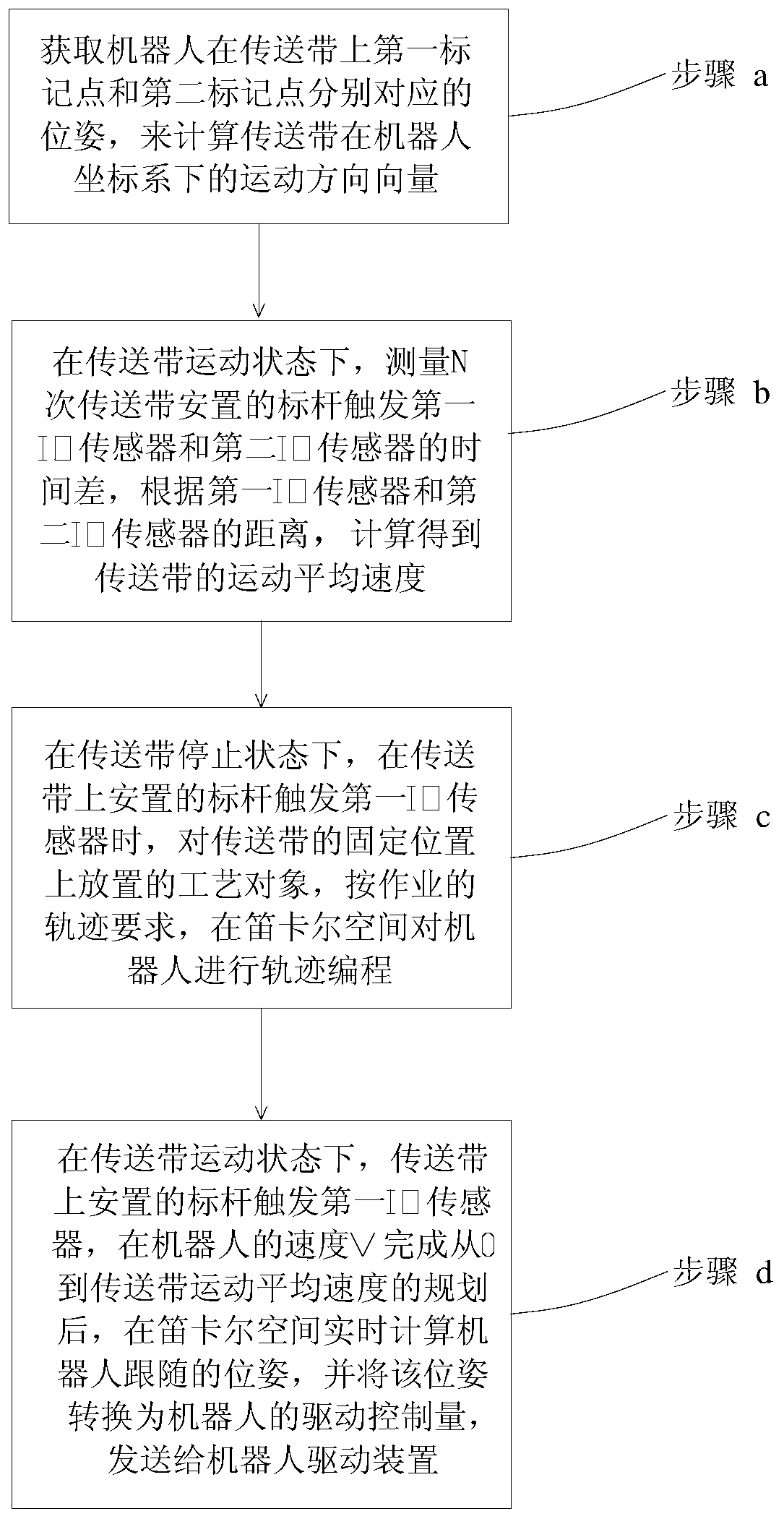

[0045] like Figure 1 ~ Figure 3 As shown, the present invention provides a method for controlling the robot to follow the movement of the conveyor belt, which is described in conjunction with the structure, and specifically includes the following steps:

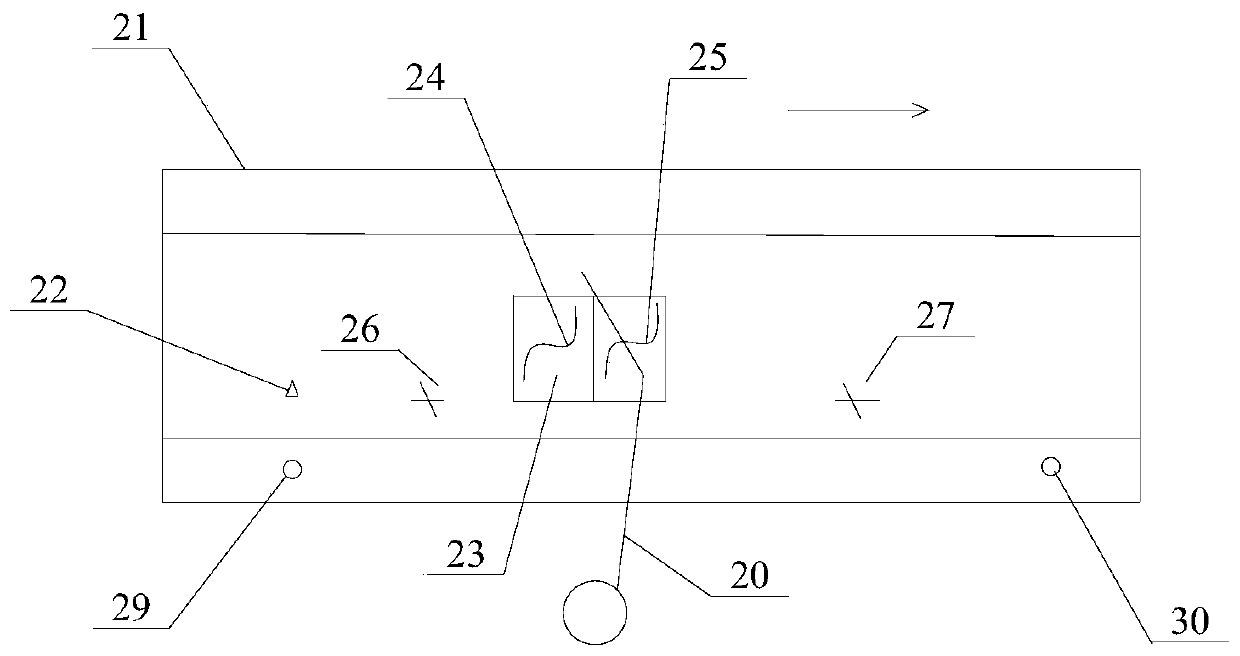

[0046] Step a, obtain the poses p0 (x0, y0, z0, w0, p0, r0), p1 (x1, y1, z1, w1, p1, r1), the first marking point 26 can be completely overlapped to the second marking point 27 by the movement of the conveyor belt 21, then:

[0047] The motion direction vector is (x1-x0, y1-y0, z1-z0), and the direction is figure 2 in the direction of the arrow;

[0048] The result after unitization is: vector_belt(belt_dx,belt_dy,belt_dz);

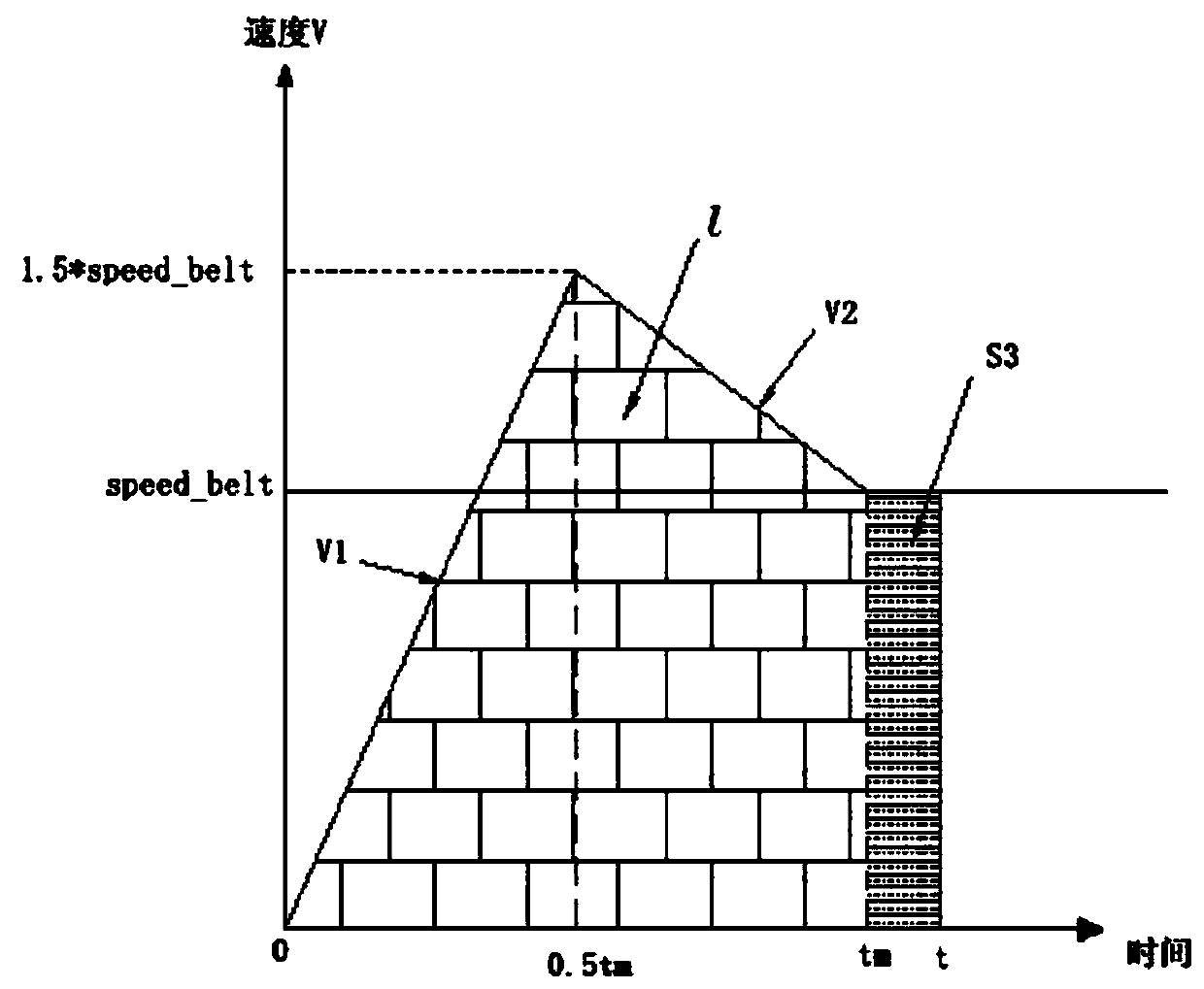

[0049]Step b, in the moving state of the conveyor belt 21, measure the time difference time_io of the first IO sensor 29 and the second IO sensor 30 triggered by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com