Packaging structure on barreled drinking water barrel

A drinking water barrel and packaging structure technology, applied in packaging, transportation, packaging, closing, etc., can solve problems such as troublesome water changes, high cost, hidden dangers of drinking water safety, etc., and achieve the effect of preventing water leakage and preventing bacteria from entering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

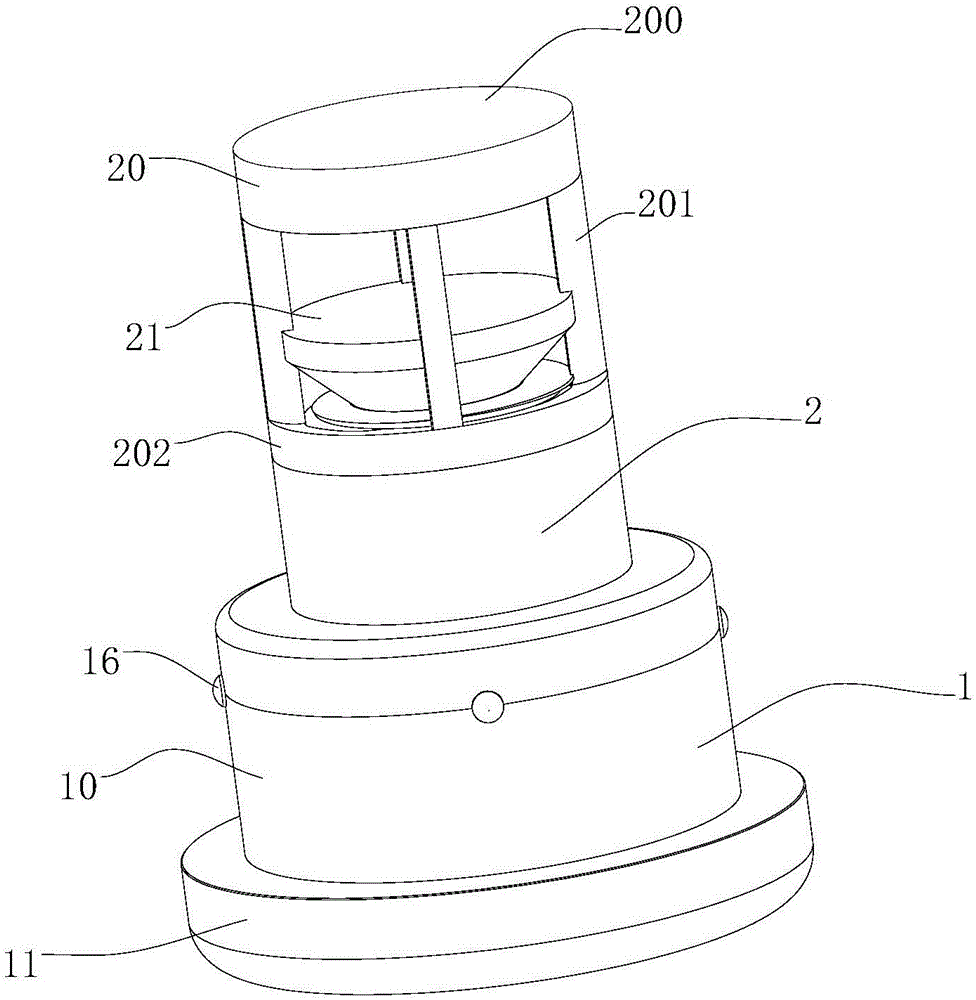

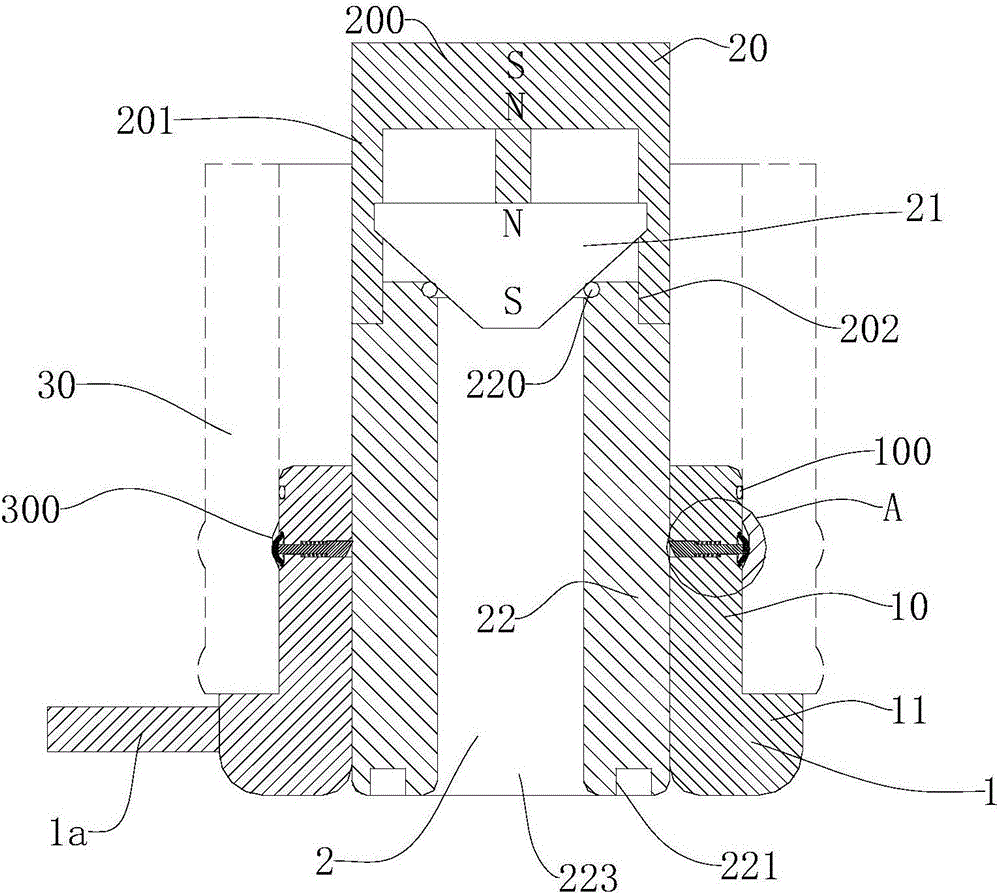

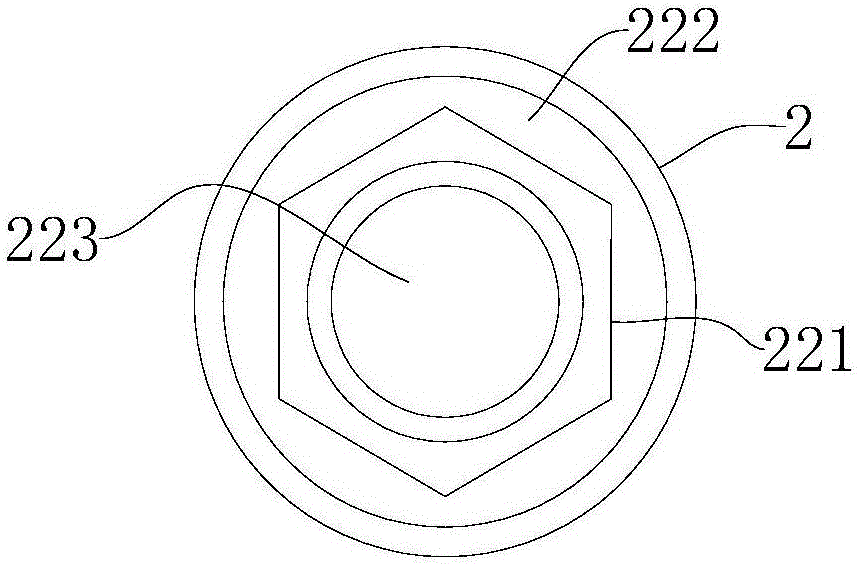

[0026] Such as Figure 1-4 Shown is a packaging structure on a drinking water bucket with an inner concave edge 300 for the mouth of the bucket drinking water bucket. The packaging structure includes a hard mounting part 1 and a hard Quality leakage core part 2, hard mounting part 1 and hard leakage core part 2 main bodies are all made of non-rusting metal material. Stainless steel or other stainless alloy materials can be used as the non-rusting metal material. This kind of hard and healthy material is used to prepare parts, which can effectively prevent the release of toxic substances when the packaging structure is soaked in hot water when the water dispenser is heated. Wherein, the hard mounting part 1 is provided with an inner hole passing through the drinking water barrel, and the hard leaking core part 2 is connected in the inner hole of the hard mounting part 1 by screw connection, therefore, in order to better fit into the hard leaking core part 2. The bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com