Method for predicting adiabatic shear sensitivity of pure copper and copper alloys using valence electron structure theory

An electronic structure, adiabatic shearing technology, applied in chemical property prediction, electrical digital data processing, special data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A method for predicting the adiabatic shear sensitivity of pure copper and copper alloys using valence electron structure theory, comprising the steps of:

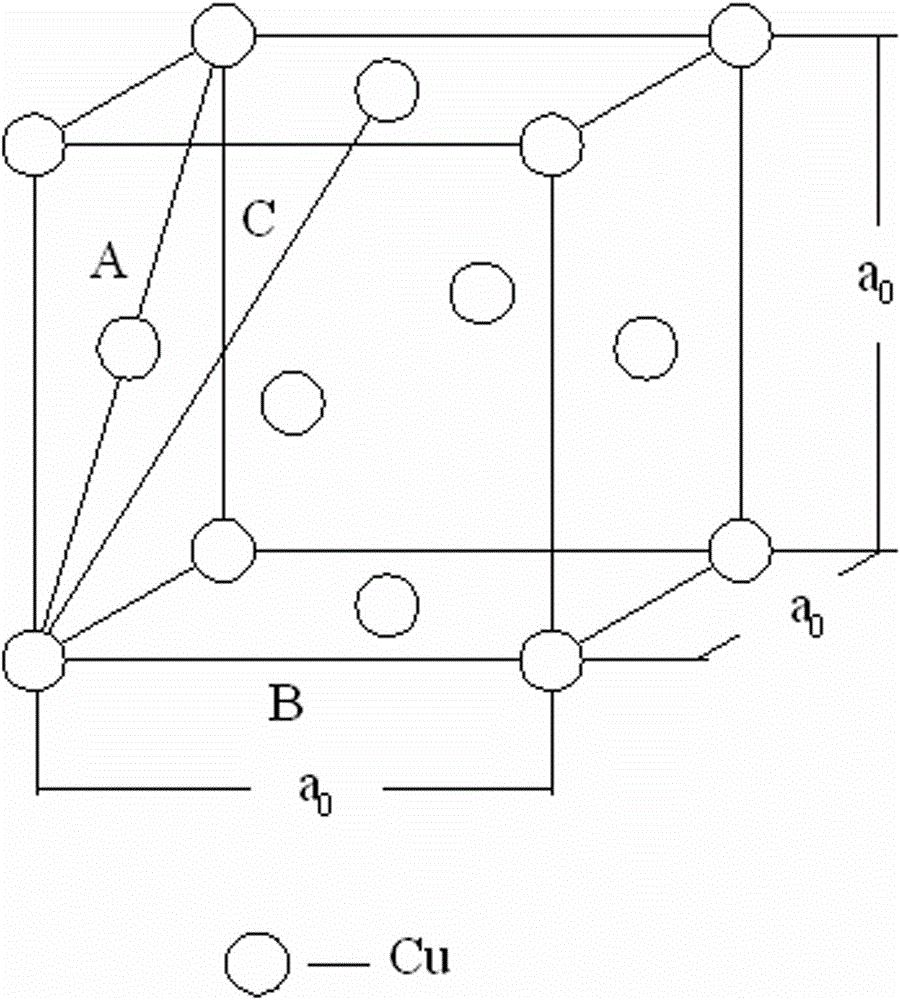

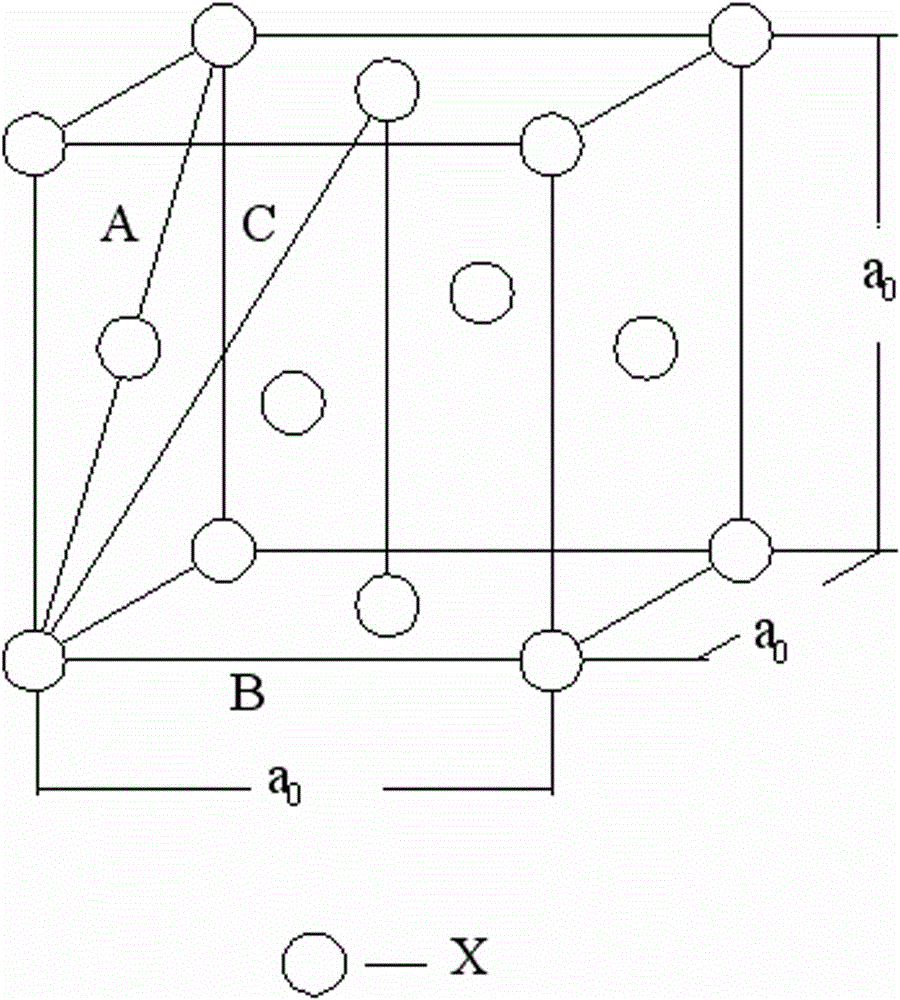

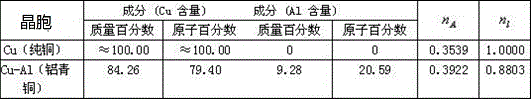

[0042] (1) Applying the above principles, taking pure copper and aluminum bronze as examples to calculate the electronic structure parameters

[0043] The hybrid double state of pure copper is:

[0044] h state: :

[0045] t state: :

[0046]

[0047] In the formula, represent n c , represent n l . Table 1 shows the hybridization table of Cu calculated according to the above hybrid double state and formulas (1)-(6).

[0048] σ 1 2 3 4 5 6 7 8 9 C hσ

1.0000 0.9999 0.9998 0.9983 0.9752 0.9502 0.9415 0.7997 0.7248 C tσ

0 0.0001 0.0002 0.0017 0.0248 0.0498 0.0585 0.2003 0.2752 n Tσ

5.0000 5.0002 5.0005 5.0035 5.0497 5.0995 5.1169 5.4006 5.5503 n lσ

1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com