A kind of preparation method of highly soluble aflatoxin-free rice bran protein

A technology of aflatoxin and rice bran protein, which is applied in plant protein processing, protein food ingredients, protein food processing, etc., can solve the problems of affecting solubility, protein denaturation, and difficult to be used, so as to improve extraction, improve, and accelerate degradation function, the effect of promoting the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

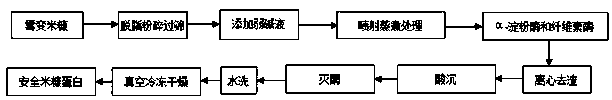

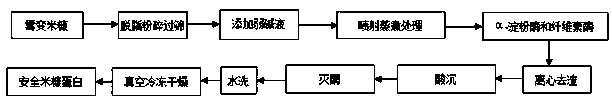

Method used

Image

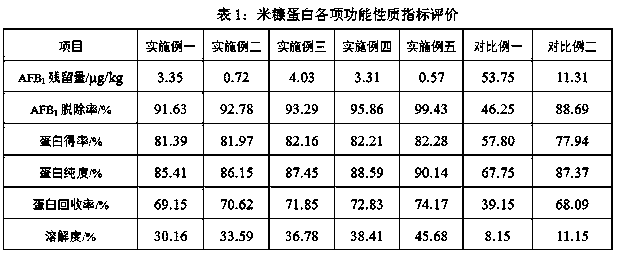

Examples

Embodiment 1

[0021] (1) Add dilute lye: take aflatoxin to pollute rice bran, that is, moldy rice bran, and rice bran contains Aspergillus aflatoxin AFB 1 The content is 40 μg / kg. After degreasing, crush and sieve at room temperature, add 0.02mol / L dilute NaOH solution at a ratio of 1:8 to liquid, adjust the pH to 8.20, and then stir in a water bath for 30 minutes.

[0022] (2) Jet cooking treatment: set the above mixed solution to a cooking temperature of 100°C and a treatment time of 45 seconds.

[0023] (3) Enzymatic treatment Adjust the pH of the liquid treated in step (2) to 6.00, add 3200 U / g α-amylase and 1200 U / g cellulase for hydrolysis to remove impurities such as starch and fiber, and obtain enzymatic hydrolysis liquid.

[0024] (4) Centrifuge to remove slag: centrifuge the solution obtained in step (3) at room temperature at 6000 r / min, and take the supernatant after 5 minutes.

[0025] (5) Acid precipitation: add 0.06 mol / L hydrochloric acid to the supernatant obtained in (4)...

Embodiment 2

[0028] (1) Add dilute lye: take aflatoxin to pollute rice bran, that is, moldy rice bran, and rice bran contains Aspergillus aflatoxin AFB 1 The content is 10 μg / kg. After degreasing, crush and sieve at room temperature, add 0.04mol / L dilute NaOH solution at a ratio of 1:9 to liquid, adjust the pH to 8.20, and then stir in a water bath for 30 minutes.

[0029] (2) Jet cooking treatment: set the above mixed solution to a cooking temperature of 105°C and a treatment time of 50 seconds.

[0030] (3) Enzymatic treatment Adjust the pH of the liquid treated in step (2) to 6.00, add 3400 U / g α-amylase and 1400 U / g cellulase for hydrolysis to remove impurities such as starch and fiber, and obtain enzymatic hydrolysis liquid.

[0031] (4) Centrifuge to remove slag: centrifuge the solution obtained in step (3) at room temperature at 7000 r / min, and take the supernatant after 5 minutes.

[0032] (5) Acid precipitation: Add 0.08 mol / L hydrochloric acid to the supernatant obtained in (4) a...

Embodiment 3

[0035] (1) Add dilute lye: take aflatoxin to pollute rice bran, that is, moldy rice bran, and rice bran contains Aspergillus aflatoxin AFB 1 The content is 60 μg / kg. After degreasing, crush and sieve at room temperature, add 0.06mol / L dilute NaOH solution at a ratio of 1:10 to liquid, adjust the pH to 8.20, and then stir in a water bath for 30 minutes.

[0036] (2) Jet cooking treatment: set the above mixed solution to a cooking temperature of 110°C and a treatment time of 55 seconds.

[0037] (3) Enzymatic treatment Adjust the pH of the liquid treated in step (2) to 6.00, add 3600 U / g α-amylase and 1600 U / g cellulase for hydrolysis to remove impurities such as starch and fiber, and obtain enzymatic hydrolysis liquid.

[0038] (4) Centrifuge to remove slag: centrifuge the solution obtained in step (3) at room temperature at 8000 r / min, and take the supernatant after 6 minutes.

[0039] (5) Acid precipitation: Add 0.09 mol / L hydrochloric acid to the supernatant obtained in (4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| escape rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com