Viscous and dense material discharging device and viscous and dense material manufacturing system

A technology of discharging device and material, applied in the direction of feeding device, chemical/physical/physical chemical process, chemical/physical process, etc., can solve problems such as gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

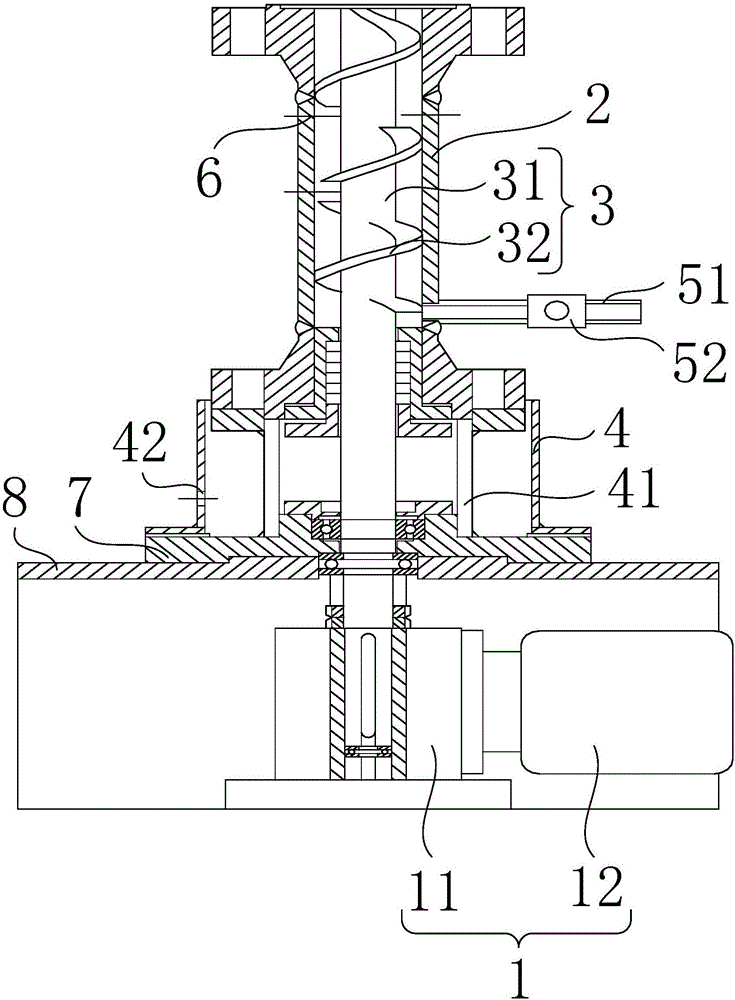

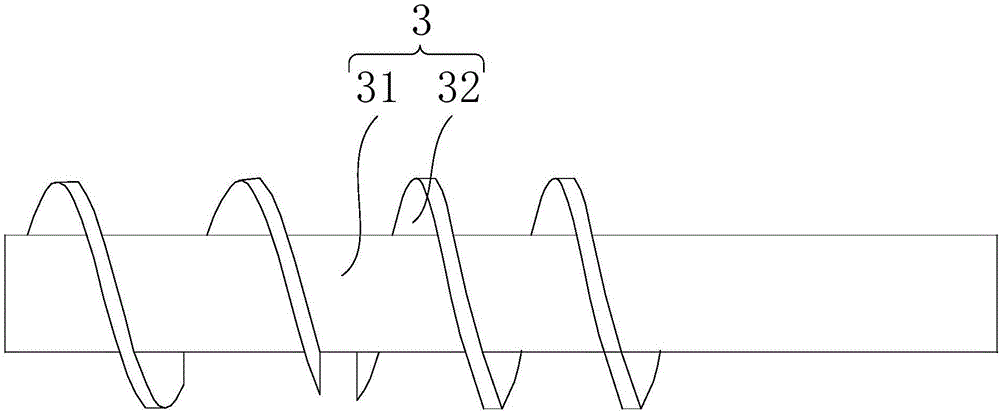

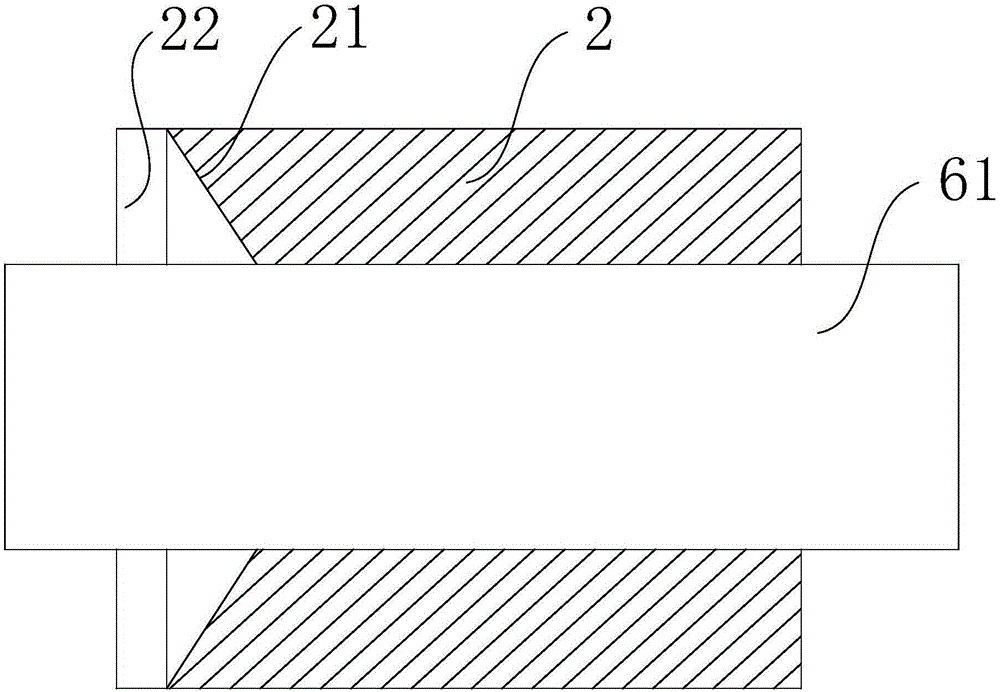

[0029] figure 1 Provide the structural representation of viscous material discharging device for the embodiment of the present invention, as figure 1 As shown, the viscous material discharge device provided by the embodiment of the present invention includes: a driving mechanism 1, a material delivery housing 2, an extrusion mechanism 3 and a stuffing chamber, and the material delivery housing 2 is provided with a material inlet and a material outlet , the stuffing chamber is connected with one end of the material delivery housing 2, the stuffing chamber is provided with a gas collecting part, the extruding mechanism 3 includes a shaft body 31 and a screw blade 32, the screw blade 32 is installed on the shaft body 31, and the shaft body 31 passes through The material delivery housing 2 is connected to the stuffing chamber and the driving mechanism 1 , the screw blade 32 is located in the material delivery housing 2 , and a first sealing member is arranged between the stuffing ...

Embodiment 2

[0046] The purpose of the second embodiment is to provide a viscous material manufacturing system to solve the technical problem of gas leakage during the viscous material discharge process in the prior art.

[0047] The viscous material production system provided in the second embodiment includes a reactor and the viscous material discharge device as in the above embodiment 1, and the feed port of the conveying shell 2 in the viscous material discharge device is connected to the reactor.

[0048] In the viscous material discharge device, a flange is provided at the feed port of the material conveying shell 2, and the material conveying shell 2 is connected with the discharge port of the reactor through the flange. The viscous material manufacturing system has the same advantages as the above-mentioned viscous material discharging device compared with the prior art, and will not be repeated here.

[0049] Specifically, the viscous material production system includes a modified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com