Pressing clamping device

A clamping device and support rod technology, applied in the field of workpiece clamping devices, can solve the problems of workpiece displacement, poor clamping effect, complex structure of irregular parts, etc., and achieve the effect of increasing the lateral distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

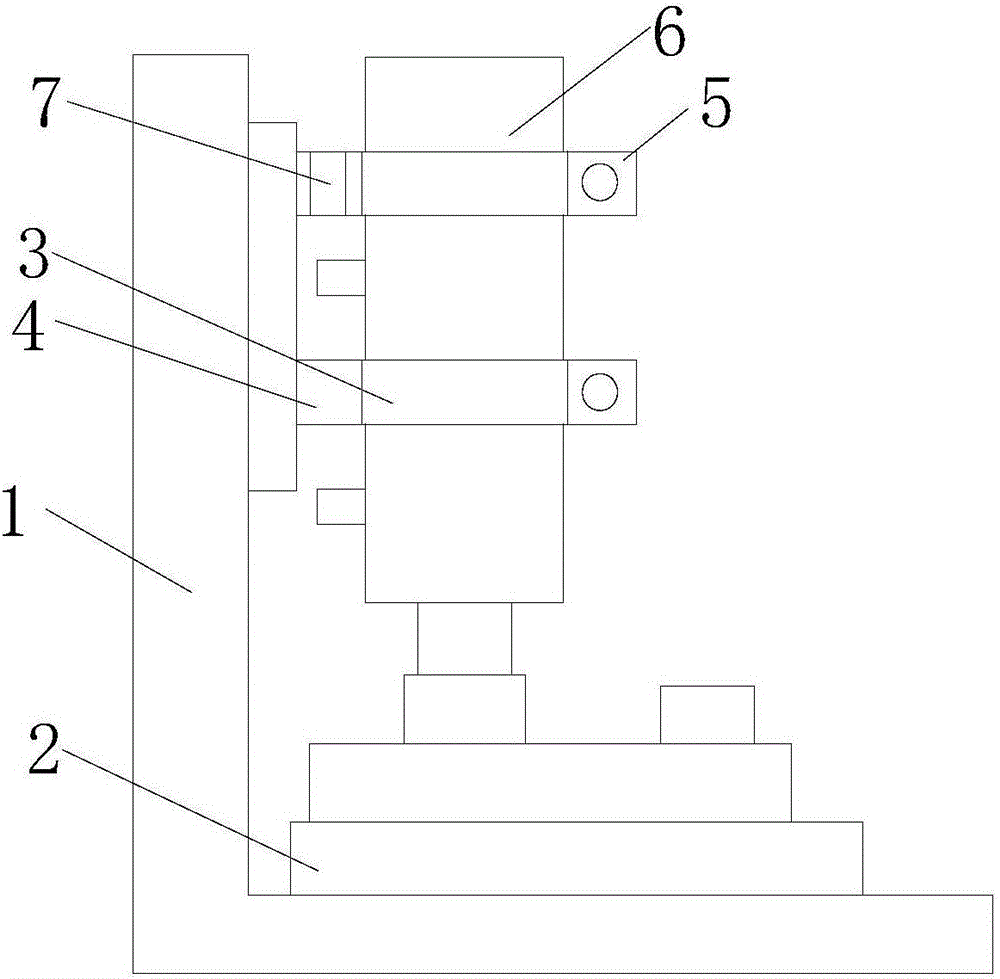

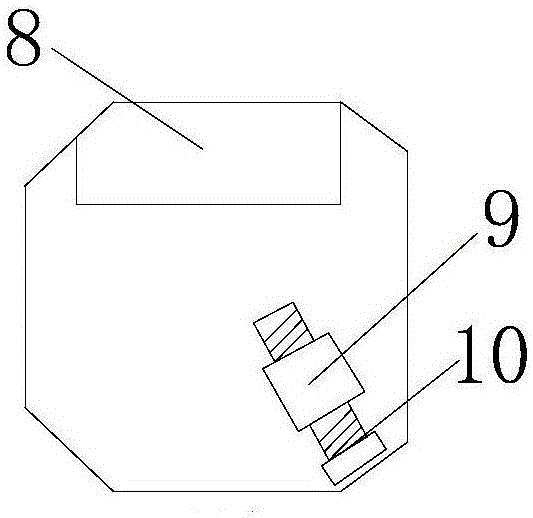

[0013] see figure 1 As shown, a downward clamping device is characterized in that it includes an "L"-shaped bracket 1, a base 2 is provided on the horizontal part of the bracket, and at least one collar 3 with a notch is provided on the vertical part; The collar is connected with the vertical part by a support rod 4, and the two ends of the collar at the gap extend outwards to form an extension rod 5, which is provided with screw holes; Cylinder 6, the telescoping end of this cylinder is towards base. The workpiece is pressed down through the telescopic end of the cylinder; the cylinder is clamped on the collar by screwing the bolt into the screw hole, and the collar fixes the cylinder on the bracket and makes the telescopic end of the cylinder face downward; by setting the support rod , increasing the lateral distance between the collar and the bracket allows the cylinder to be located in the middle of the base.

[0014] A through hole 7 is provided on the support rod. By ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com