Rotor structure with long-acting operation

A rotor structure, long-term technology, applied to components of pumping devices for elastic fluids, non-variable pumps, axial flow pumps, etc., can solve problems such as easy accumulation of dust particles, fragmentation, and short maintenance periods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

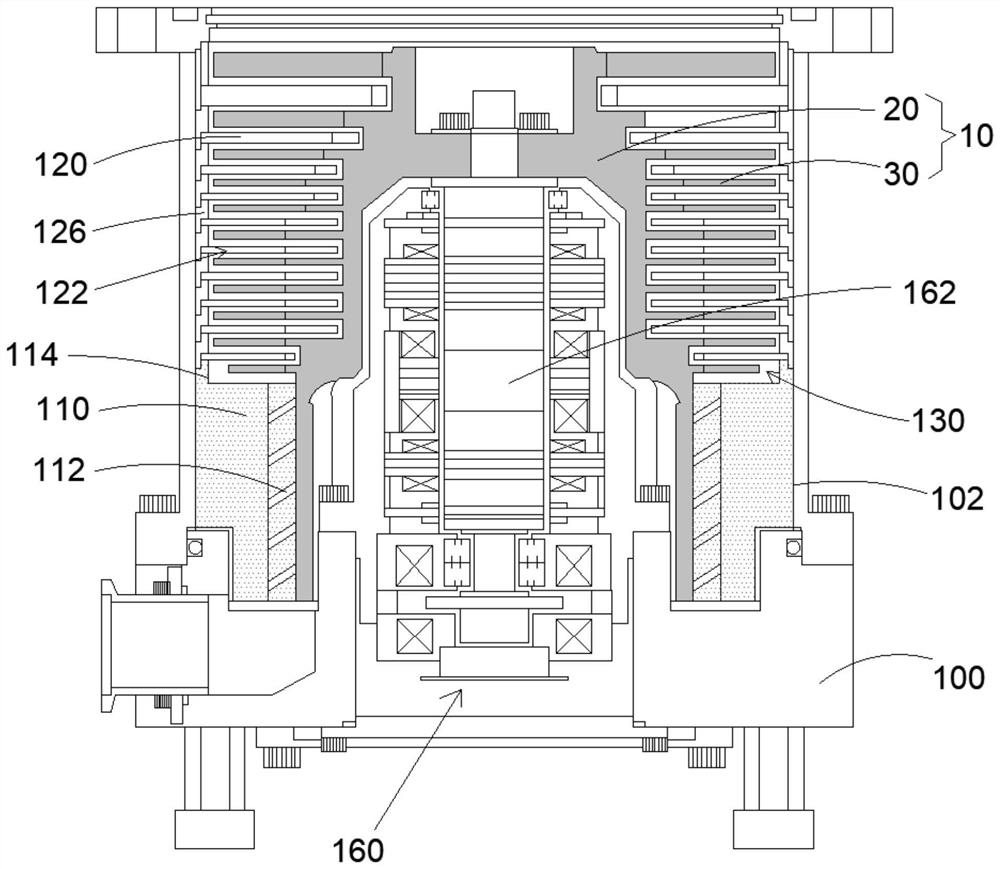

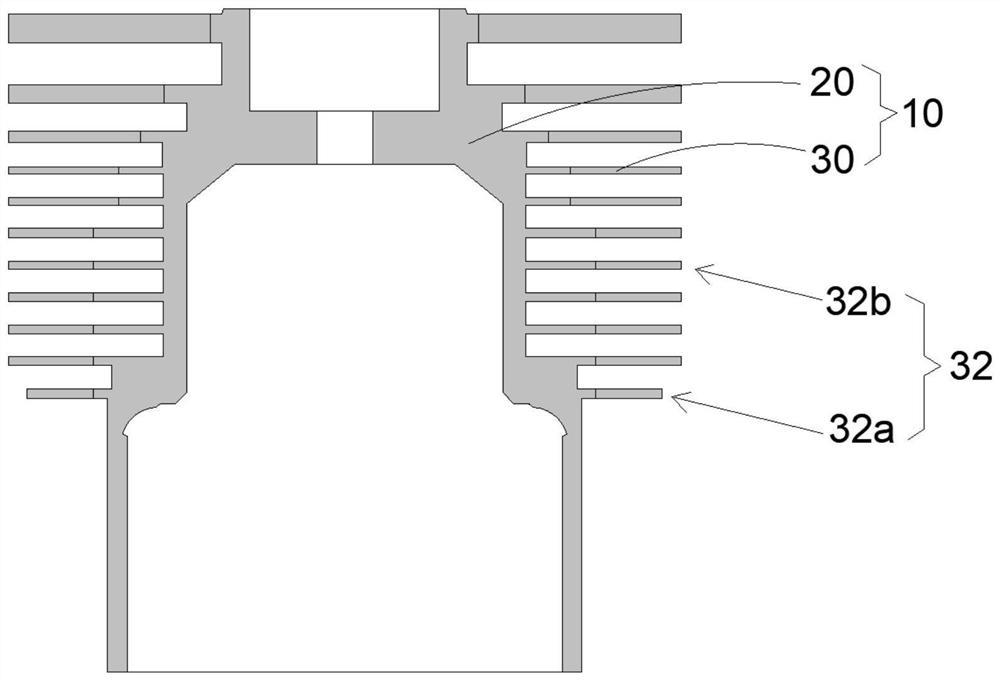

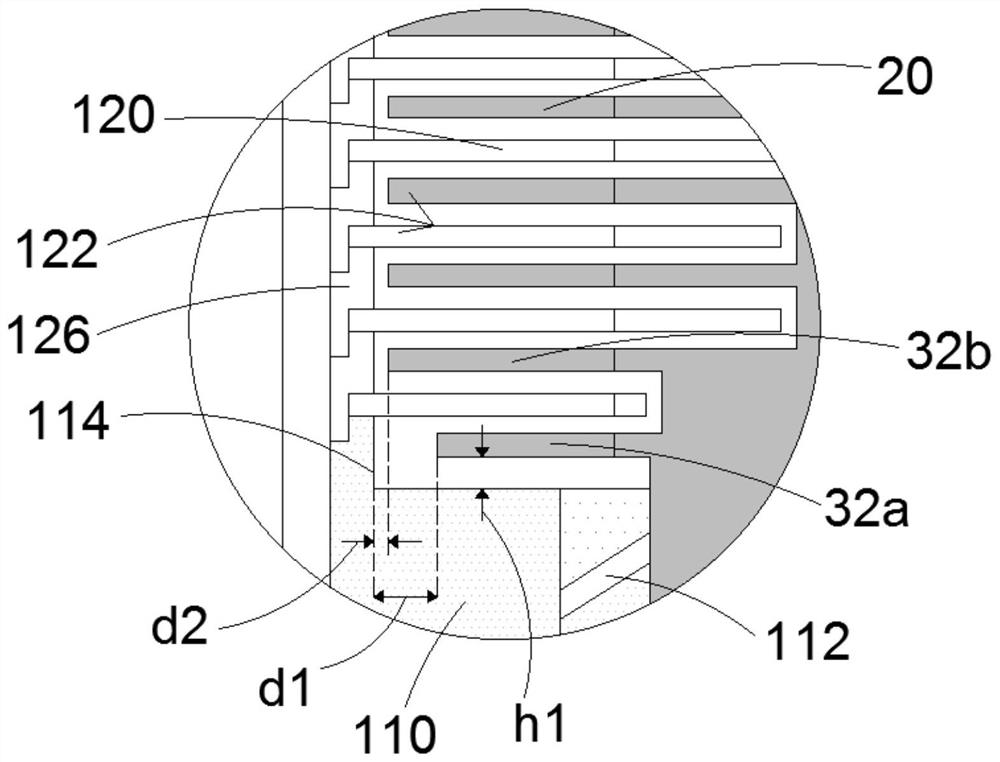

[0044] In order to facilitate the understanding of the technical features, content and advantages of the present invention and the effects that can be achieved, the present invention is hereby combined with the drawings and described in detail as follows in the form of embodiments, and the purposes of the drawings used therein are only For the purpose of illustrating and assisting the description, it may not be the true proportion and precise configuration of the present invention after implementation, so the scale and configuration relationship of the attached drawings should not be interpreted to limit the scope of rights of the present invention in actual implementation. In addition, for ease of understanding, the same components in the following embodiments are described with the same symbols.

[0045] In addition, the terms used in the entire specification and claims, unless otherwise specified, generally have the ordinary meaning that each term is used in this field, in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com