A high-speed rapier towel loom

A towel loom and rapier technology, applied in looms, flannel looms, textiles, etc., can solve the problems of low precision of raising mechanism parts, insufficient overall frame strength, insufficient beating force, etc., and improve the working environment. , cost-effective, small vibration effect of machine work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

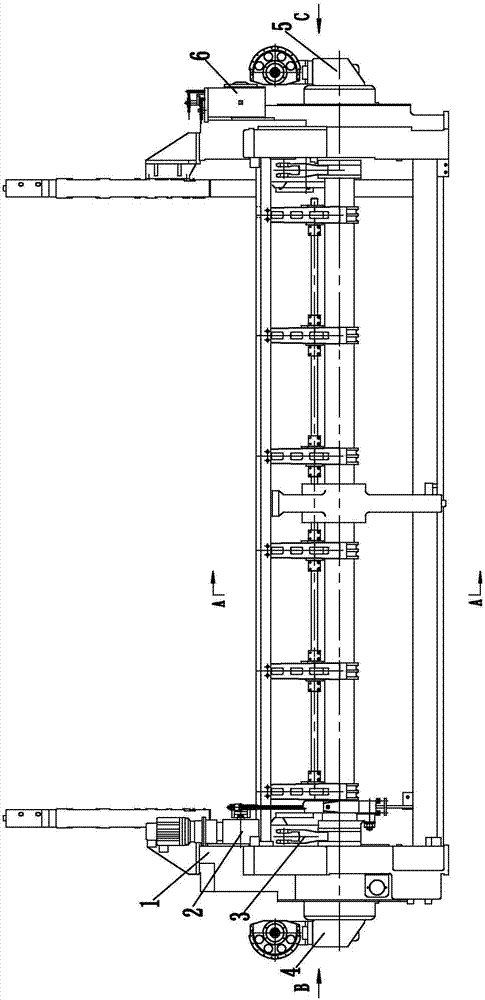

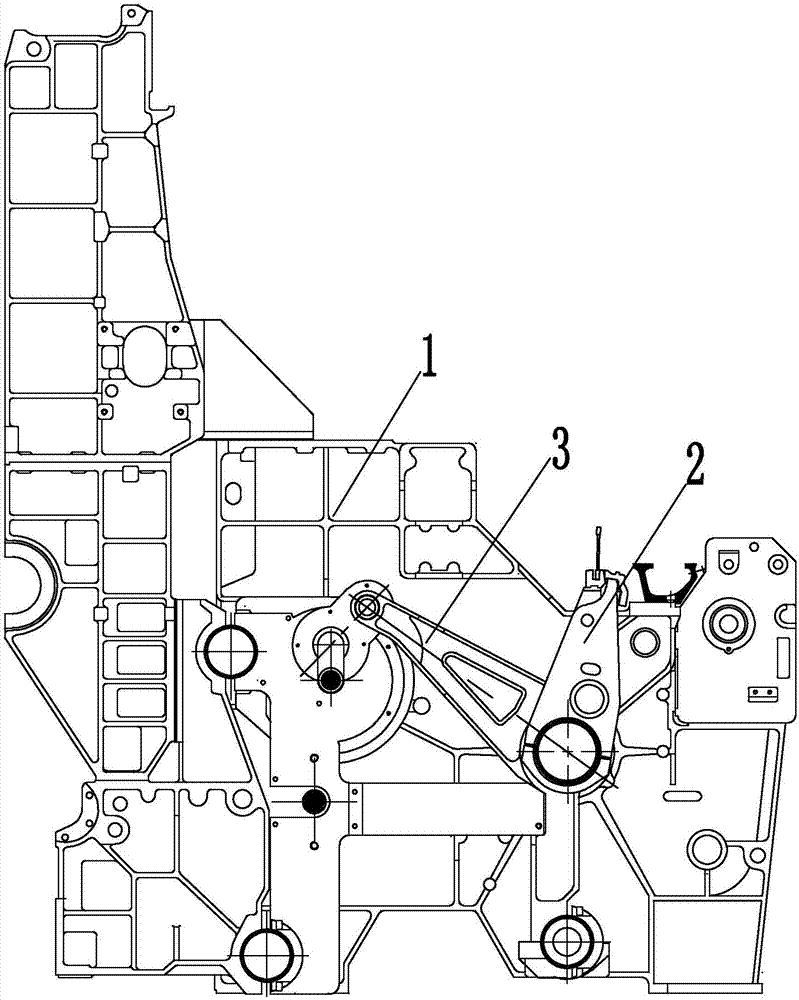

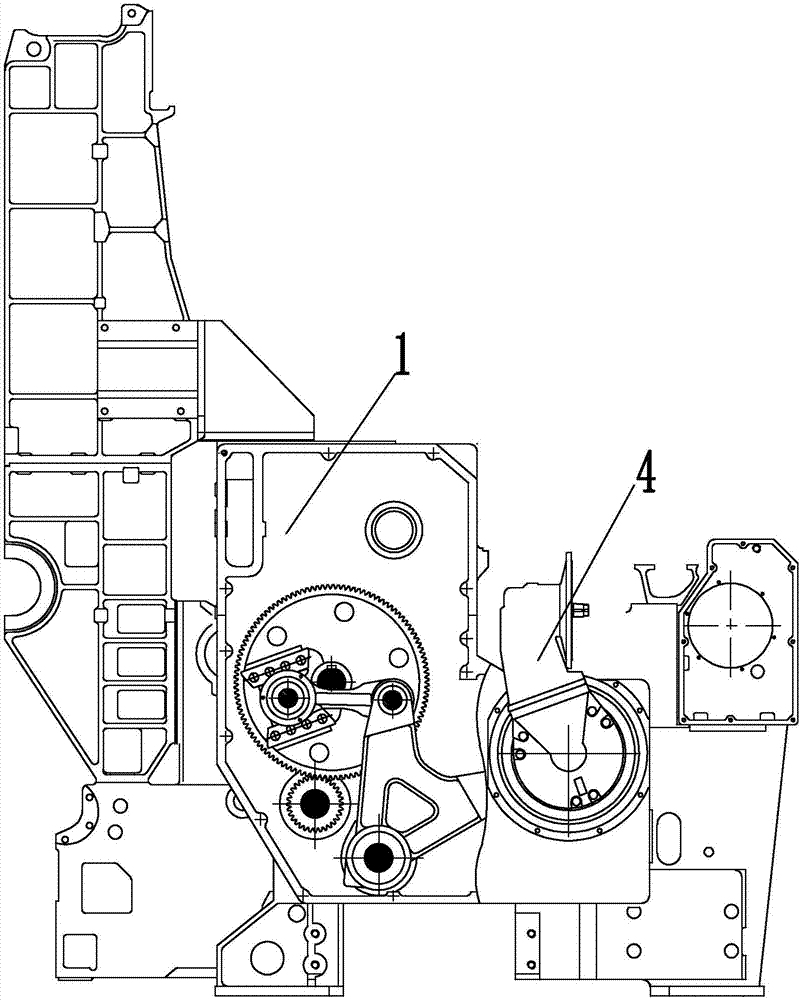

[0063] Such as Figure 1-22 As shown, the high-speed rapier towel loom of the present invention includes a frame on which a raising device, a weft beating device, a left weft insertion device, a right weft insertion device and an independent hemming device are installed on the frame. Including the left wallboard and the right wallboard, the raising device is installed in the middle of the frame and inside the left wallboard; the beating device is installed in the middle of the frame and inside the left and right wallboards; the left weft insertion device is installed on the left side of the frame Outside and inside the left wallboard; the right weft insertion device is installed on the right outside of the frame and inside the right wallboard; the independent hemming device is installed on the right wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com