Liquid dispensing pot

A sub-packaging and liquid technology, applied in household containers and other directions, can solve the problem that the pot body cannot be sub-packed with multiple liquids at the same time, and achieve the effects of avoiding liquid interpenetration, reducing quantity and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with examples, but the present invention is not limited to these examples.

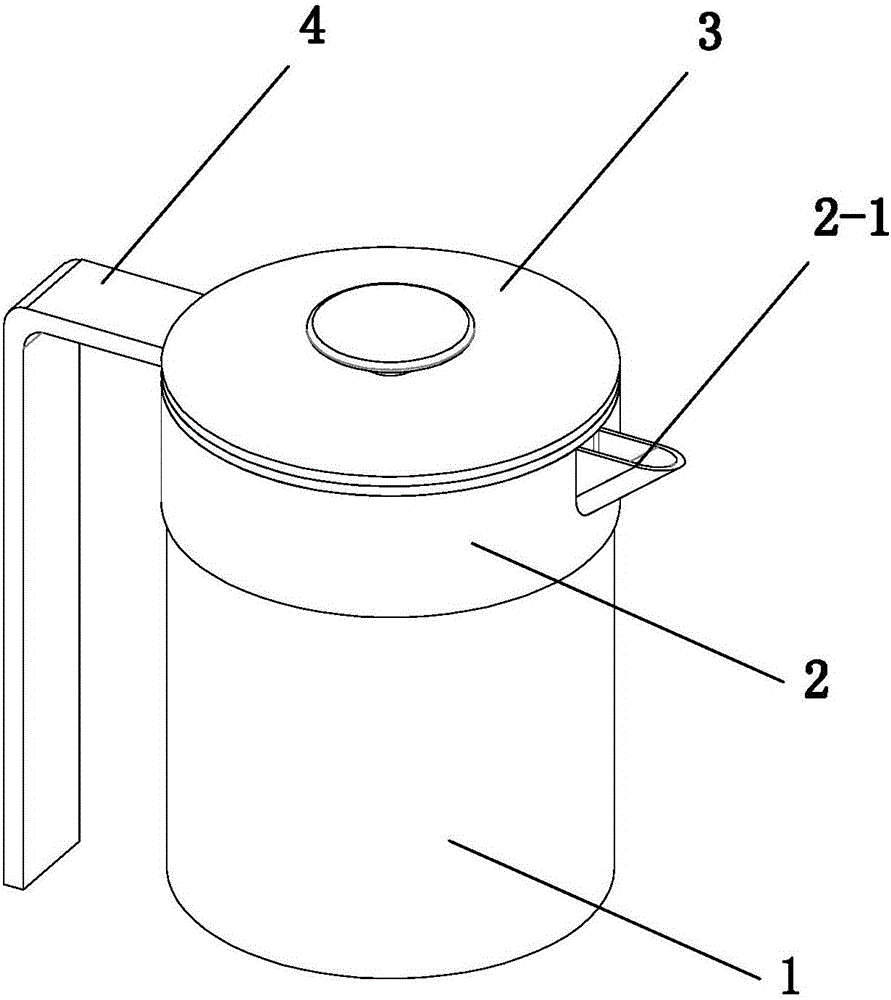

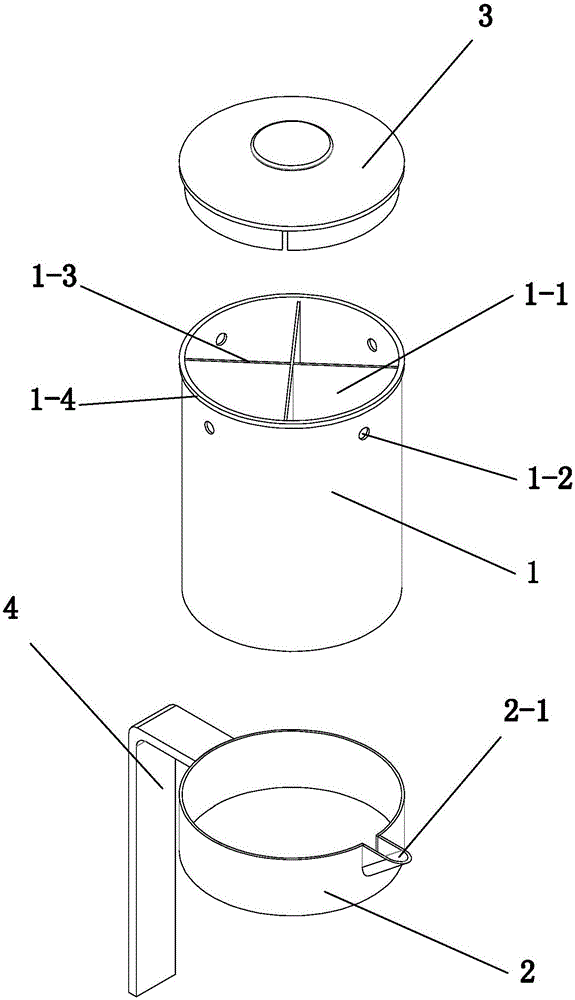

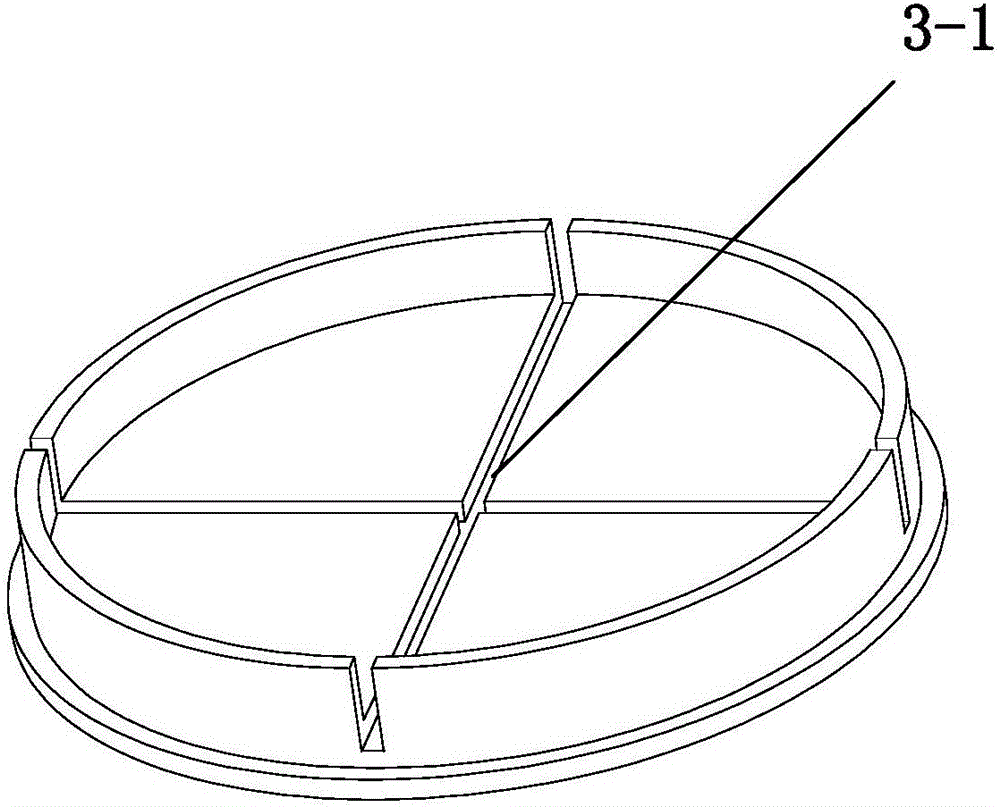

[0023] Liquid dispensing pot, the pot body is mainly composed of a cylindrical pot core 1 inside and a retaining ring 2 surrounding the outside of the pot core 1. The pot core 1 can rotate in the retaining ring 2, as attached figure 1 And attached figure 2 shown. There are at least two fan-shaped sub-packing grooves 1-1 inside the kettle core 1, and the sub-packing grooves 1-1 are distributed fan-shaped starting from the central axis of the cylindrical pot core 1, and one side of each sub-packing groove 1-1 is the pot core 1 side wall, the tank body and the tank body are separated by a partition wall 1-3; thus, a circular liquid outlet 1-2 for liquid to pass through can be set on the outer wall of the sub-packing tank 1-1 near the notch position, and each Each dispensing tank 1-1 corresponds to a liquid outlet 1-2.

[0024...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com