Ship with automatic side turn-preventing function

An anti-rollover and ship technology, which is applied in the direction of ship safety, ship, transportation and packaging, etc., can solve the problems of several minutes or even ten or twenty time, airbag aging damage, air leakage failure, and failure to reach ship rollover and other problems, to achieve the effect of fast inflation, simple structure and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

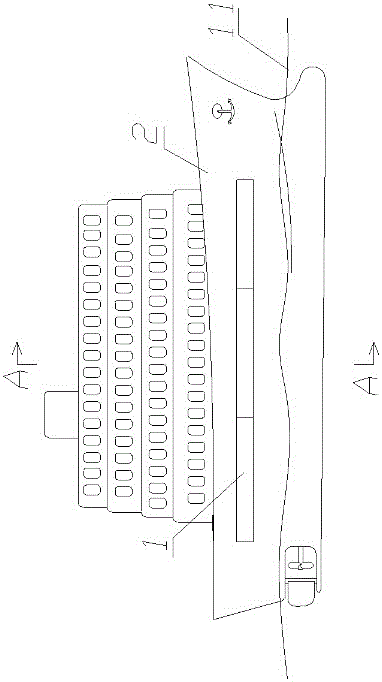

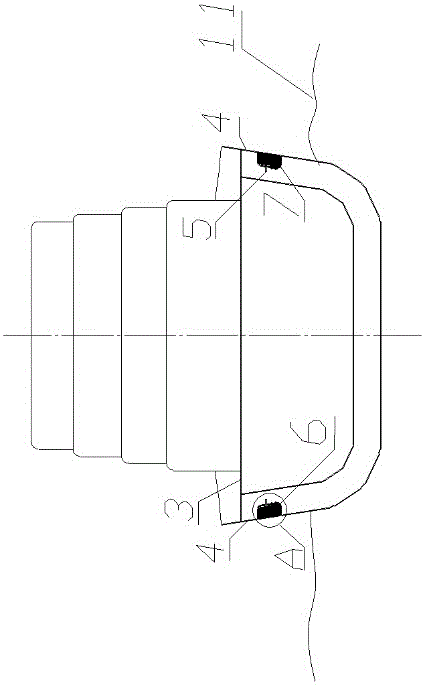

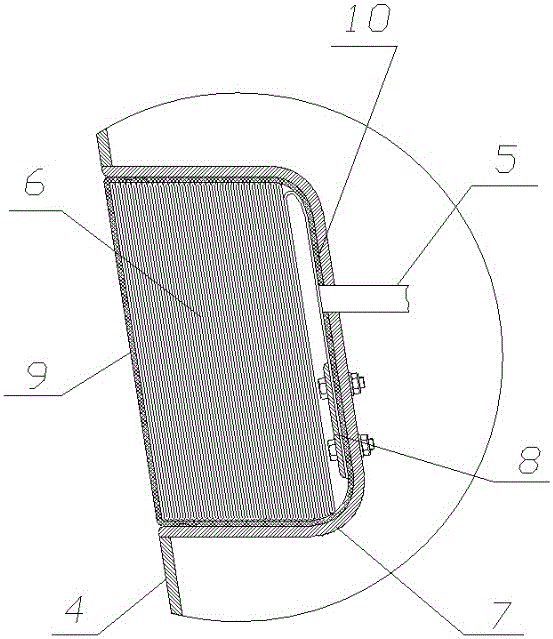

[0018] As can be seen from the accompanying drawings of the above specific embodiments, the present invention includes the air bag groove 7 recessed in the hull wall on both sides of the hull 2 and the hull, and three air bag boxes 1 are inlaid in the air bag groove 7 on each side. The airbag box 1 is divided into an airbag bottom box 10 and an airbag box cover 9, and the airbag box cover 9 is sealed and buckled with the airbag bottom box 10 toward the outside of the hull (see figure 2 and image 3 ), each airbag box 1 contains an uninflated airbag 6, and the root of the airbag 6 is positioned at the bottom of the airbag groove 7 together with the bottom box 10 through the fastener with the pressure plate 8, so that the airbag 6 is protected in the airbag box 1 It is isolated from the outside world, avoiding the influence of high humidity, high salt and strong light on the airbag 6 . Each airbag 6 has an air intake pipe 5 and a one-way valve 12 connected in series with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com