Catalyst carrier for olefin polymerization and its preparation method and application

A catalyst carrier and olefin polymerization technology, which is applied in the field of olefin polymerization, can solve problems such as increased operating costs, increased costs, and adverse effects of by-product recovery and treatment, and achieves the effect of saving raw material costs and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In a first aspect, the present invention provides a method for preparing a catalyst carrier for olefin polymerization, the method comprising:

[0028] 1) the magnesium halide shown in the general formula MgXY and the general formula R 1 The compound represented by OH is mixed with the oxirane compound and an optional inert liquid medium at a temperature not exceeding 35°C to obtain a mixture solution;

[0029] 2) heating the mixture solution obtained in step 1) to not lower than 40° C. under stirring;

[0030] Wherein, in the general formula MgXY, X is a halogen element, and Y is selected from halogen elements, C 1 -C 14 Alkyl, C 1 -C 14 Alkoxyl, C 6 -C 14 Aryl or C 6 -C 14 A group consisting of aryloxy groups;

[0031] In general formula R 1 OH, R 1 for C 1 -C 8 Alkyl or C 3 -C 8 Cycloalkyl;

[0032] The oxirane compound has a structure shown in formula (I):

[0033] Formula (I),

[0034] In formula (I), R 2 and R 3 each independently hydrogen, C ...

preparation example 1

[0086] This preparation example is used to prepare the catalyst carrier for olefin polymerization of the present invention.

[0087] In a 0.6L reaction kettle, add 0.08mol magnesium chloride, 1.7mol ethanol, and 0.3mol epichlorohydrin, and control the temperature at 25°C under stirring. After 1 hour of constant temperature reaction, start to heat up at a rate of 2°C / min. After reaching 60°C, maintain it for 20 minutes. Press filtration, wash the press filtration product 5 times with hexane, and vacuum dry to obtain catalyst support Z1 for olefin polymerization.

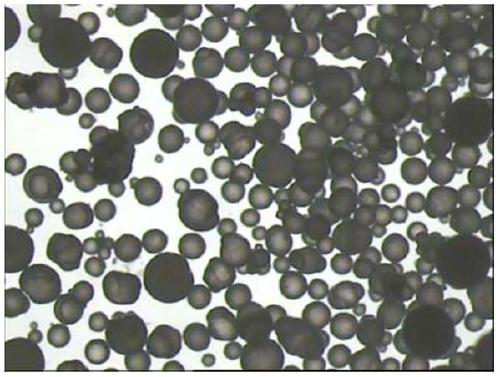

[0088] The average particle diameter (D50) of the catalyst carrier Z1 for olefin polymerization is 60 microns, and the particle size distribution ((D90-D10) / D50) is 0.9. The particle morphology observed by optical microscope is as follows figure 1 shown. It can be seen from the figure that the particle shape of the catalyst carrier Z1 for olefin polymerization is relatively regular, the surface is smooth, basically...

preparation example 2

[0093] This preparation example is used to prepare the catalyst carrier for olefin polymerization of the present invention.

[0094] In a 0.6L reaction kettle, add 0.16mol magnesium chloride, 3.4mol ethanol, and 0.6mol epichlorohydrin, and control the temperature to 30°C under stirring. After 1 hour of constant temperature reaction, start to heat up at a rate of 1°C / min. After reaching 60°C, maintain it for 20 minutes. Press filtration, wash the press filtration product with hexane for 5 times, and vacuum-dry to obtain catalyst carrier Z2 for olefin polymerization.

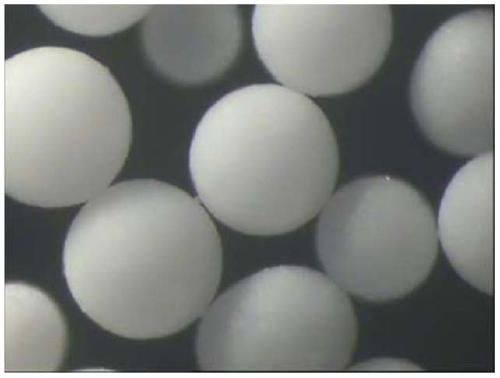

[0095] The average particle diameter (D50) of the catalyst carrier Z2 for olefin polymerization is 55 microns, and the particle size distribution ((D90-D10) / D50) is 0.8. The particle morphology observed by optical microscope is as follows figure 2 shown. It can be seen from the figure that the particle shape of the catalyst carrier Z2 for olefin polymerization is relatively regular, the surface is smooth, basi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com