Automatic collecting and cutting machine for clothes fabric string cutting pieces

A fabric, automatic technology, applied to the thread cutting mechanism in sewing machines, sewing machine components, textiles and papermaking, etc., can solve the problems of low continuous shearing efficiency and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

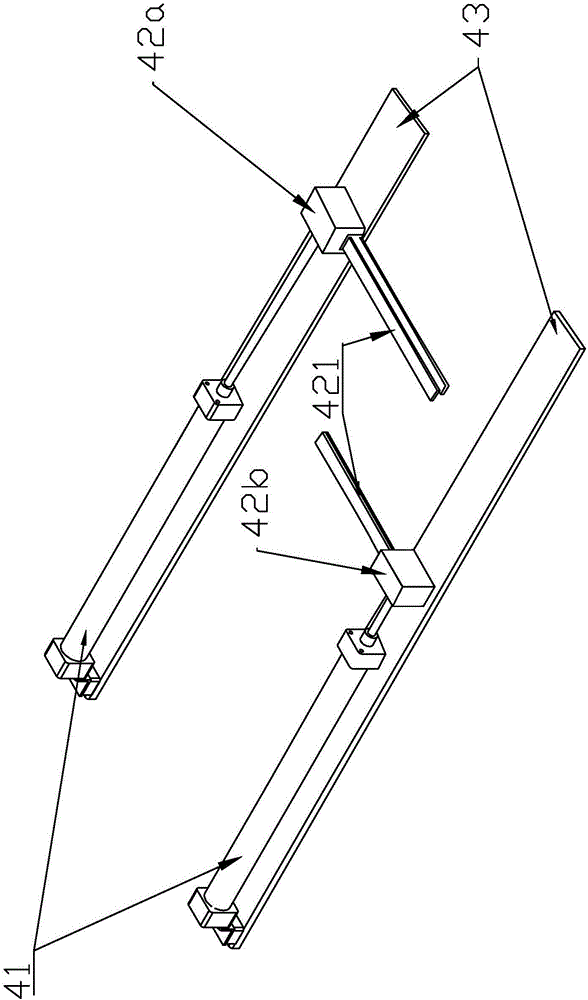

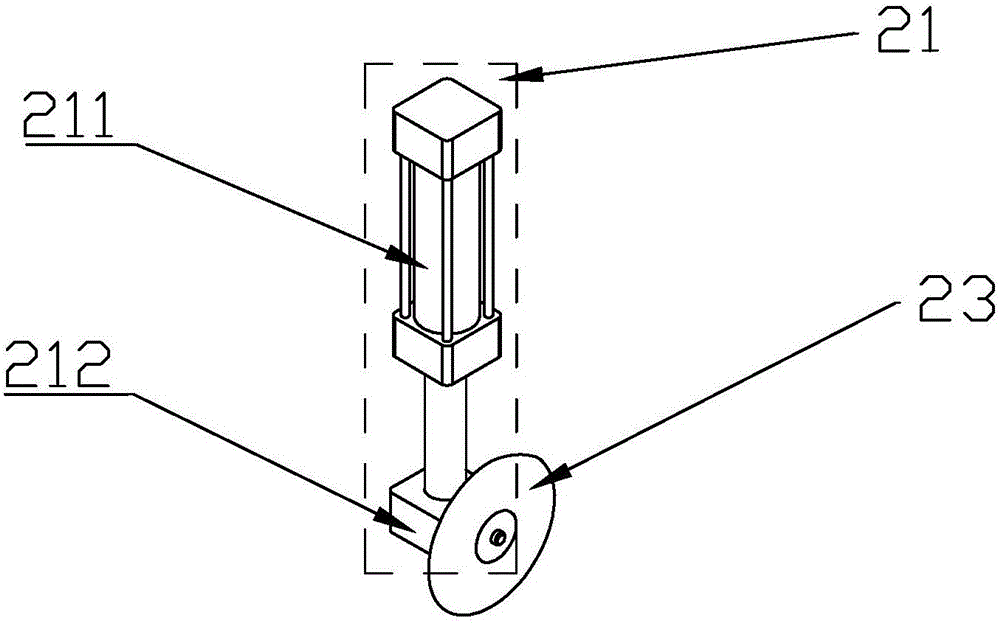

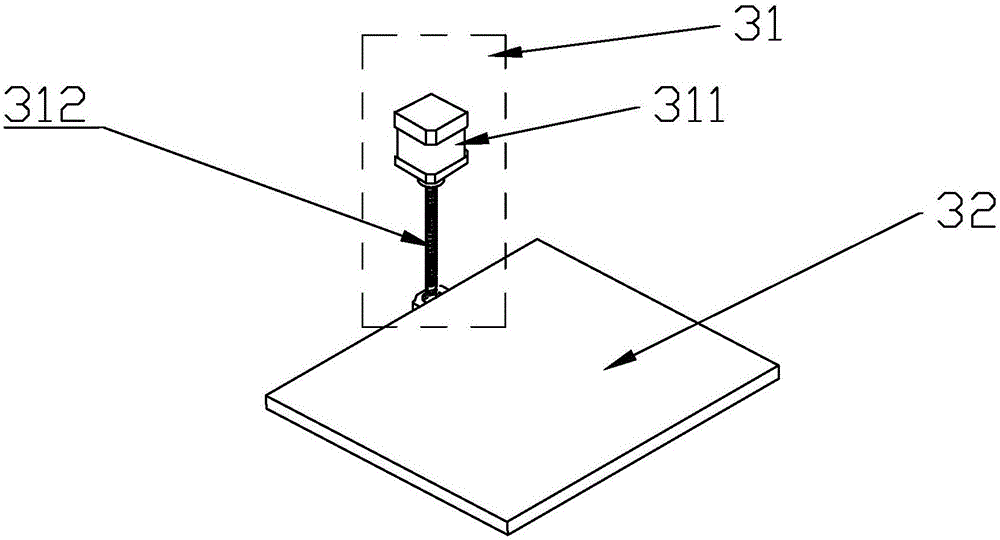

[0023] refer to Figure 7 , an automatic harvesting and cutting machine for cutting garment fabrics in series, which includes a frame 5, the frame 5 is roughly a rectangular parallelepiped frame such as Figure 6 As shown, the frame 5 is provided with a feeding mechanism 1, a cloth conveying mechanism 4, an automatic cutting mechanism 2, and an automatic cloth stacking mechanism 3. Among them such as figure 1 As shown, the cloth conveying mechanism 4 is provided with two groups of feeding claws, and the two groups of feeding claws are installed horizontally and oppositely on both sides of the frame 5 through bolts, and the feeding claws are provided with a linear guide rail 43, a power part 41 and a clamping claw part. , where the jaws can be referred to as the front jaw 42a and the rear jaw 42b according to the positions in the static state, the power part 41 is fixedly installed on the linear guide rail 43 by bolts, grooves are made on the linear guide rail 43, and the The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com