Heat bottom sealing technology and device of three-in-one lining bags

A three-in-one, lining technology, which is applied in bag making operations, paper/cardboard containers, containers, etc., can solve the problems of high cost, pinhole leakage of powdered goods, and low efficiency, so as to improve efficiency and avoid friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

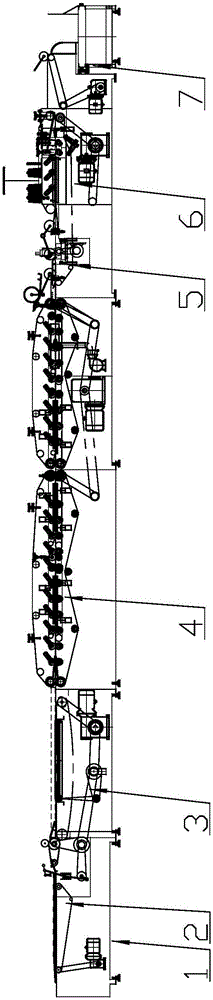

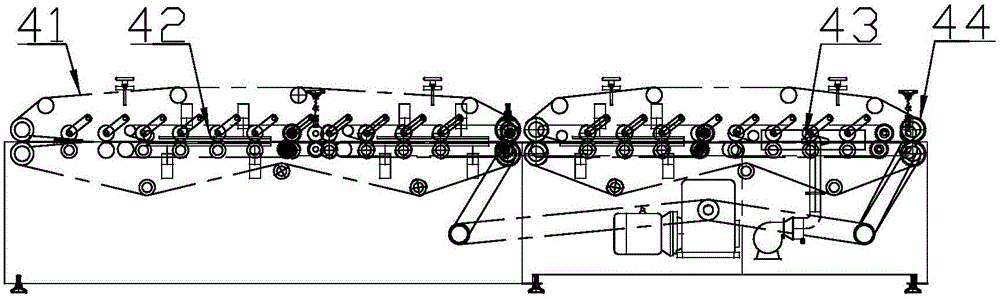

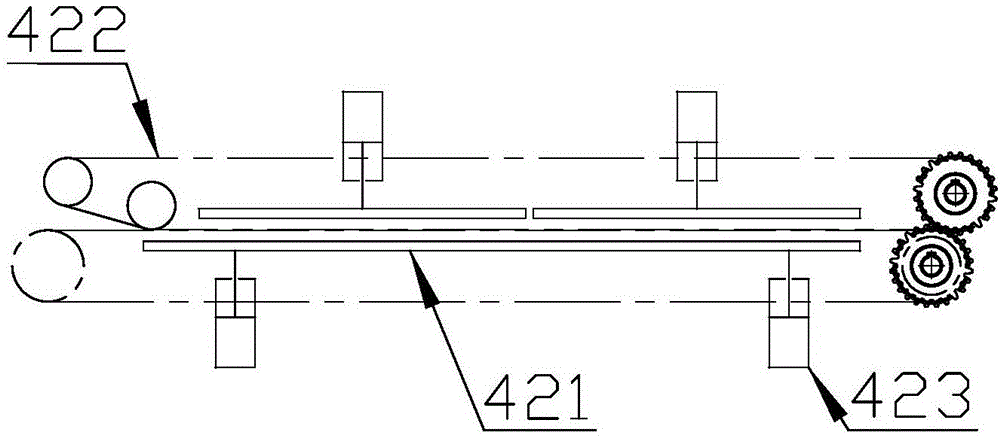

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0030] A three-in-one liner bag heat sealing bottom process, comprising the following steps:

[0031] 1) Put the three-in-one liner bag that needs to be sealed on the front end of the equipment,

[0032] 2) Transfer the three-in-one liner bag to the equipment, arrange the position of the three-in-one liner bag so that the bottom edges of the three-in-one liner bag are all aligned on the same line,

[0033] 3) Heat the bottom opening of the lining film of the three-in-one lining bag and press and heat seal the bottom,

[0034] 4) Sew the bottom opening of the three-in-one liner bag, the sewing position corresponds to the position of the heat-sealed bottom of the liner film bag,

[0035] 5) Collect the three-in-one liner bags that have gone through the above steps.

[0036] Wherein, the heating is multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com