Composite geo-membrane anchorage and floating resisting structure

A technology of composite geomembrane and anchoring structure, which is applied in the direction of infrastructure engineering, protection devices, buildings, etc., can solve the problems of not being able to eliminate uplift pressure, increase operation and management costs, and affect water quality of water storage, etc., to achieve anti-floating energy, Avoid local damage or water seepage, avoid tensile damage or produce excessive local deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

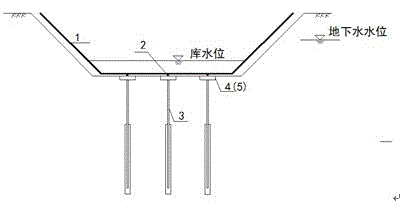

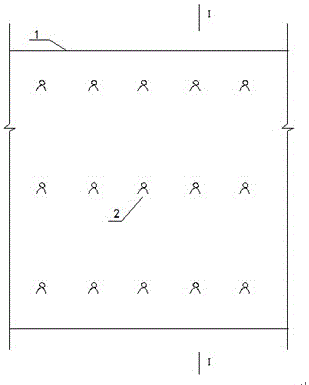

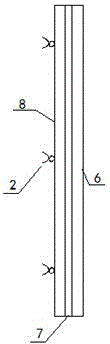

[0025] The anti-floating composite geomembrane anchoring anti-floating structure consists of an anti-floating composite geomembrane, soil anchors and an anchoring structure. The anti-floating composite geomembrane is located at the bottom of reservoirs, artificial lakes, reservoirs or municipal landfills (the woven fabric side of the anti-floating composite geomembrane is located below and directly contacts the foundation soil) to prevent leakage; The soil anchor is located in the soil layer of the foundation under the membrane to provide the anti-floating composite geomembrane with anti-floating or anti-air swelling anchoring resistance; the anchoring structure is located under the membrane, and on the one hand connects the woven fabric on the anti-floating composite geomembrane , On the one hand, it connects the soil anchor to play a connecting role. The specific implementation steps are as follows:

[0026] The first step is to produce anti-floating composite geomembrane. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com