Material distribution machine and hose clamping valve thereof

A pinch valve and pinch head technology, applied in the direction of diaphragm valve, valve device, mechanical equipment, etc., can solve the problems of hose deformation, easy material blocking, increase production cost, etc., so as to reduce production cost and ensure blanking flow. diameter, and the effect of reducing the frequency of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

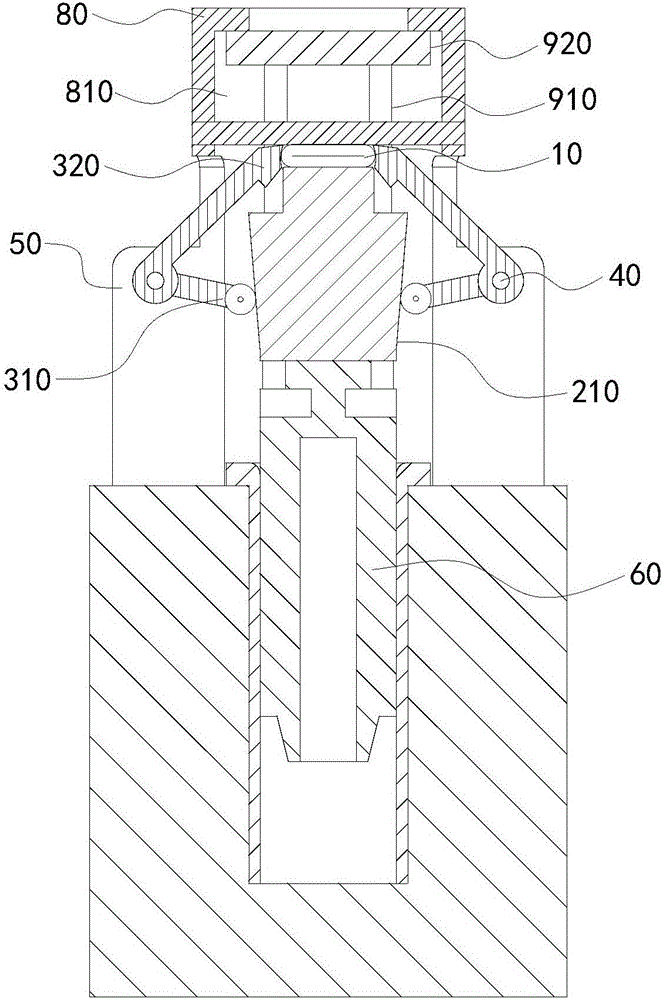

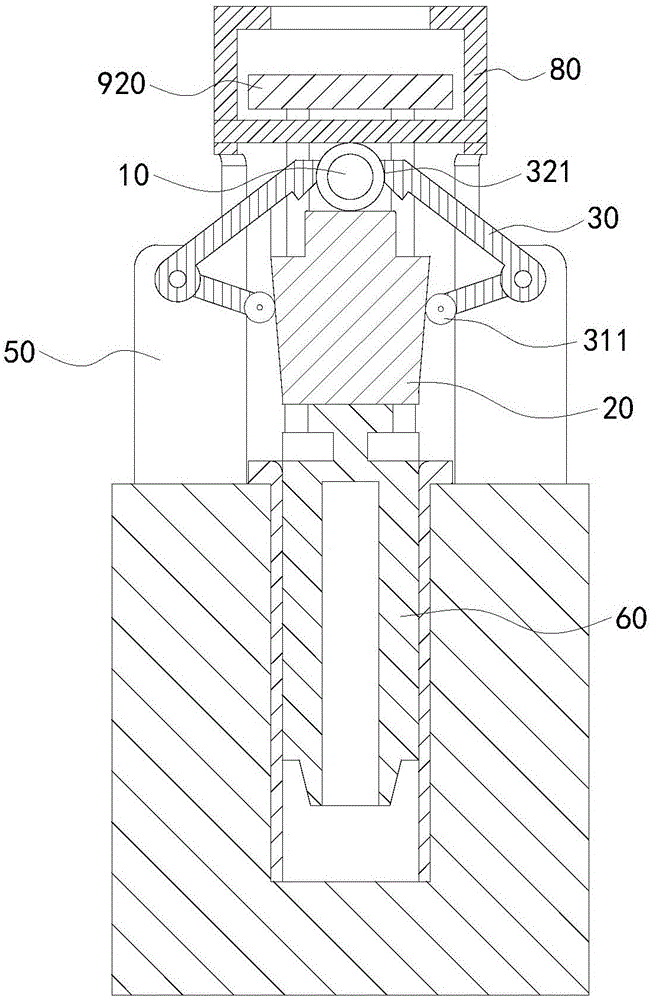

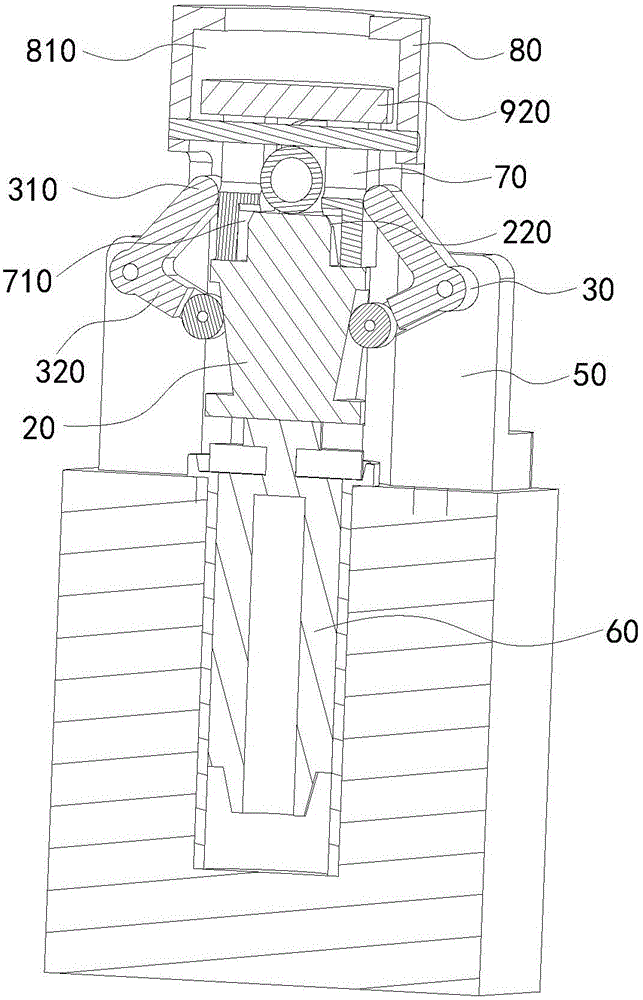

[0031] Such as figure 1 and figure 2 As shown, a pinch valve includes a recovery mechanism, a hose 10 for feeding, and a pinch head 20 for clamping or loosening the hose 10; in the first state, the recovery mechanism is far away from the hose 10 , the pinch head 20 clamps the hose 10 and squeezes and deforms the hose 10, and the hose 10 is closed; in the second state, the pinch head 20 releases the hose 10, and the recovery mechanism exerts force on the hose , And the hose 10 is restored to its original shape, and the hose 10 is opened.

[0032] The pinch valve is equipped with a recovery mechanism to ensure that after the pinch head 20 releases the hose 10, the hose 10 returns to its original shape when the material is unloaded, ensuring the maximum diameter of the blanking material, making the material unloading smooth, and ensuring normal production; Mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com