Auxiliary unloading device for light truck

A technology for auxiliary unloading devices and trucks, applied to vehicles with chains/belts, etc., can solve the problems of increased labor costs, low efficiency, and slow speed, and achieve low labor costs, high efficiency, and fast unloading speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

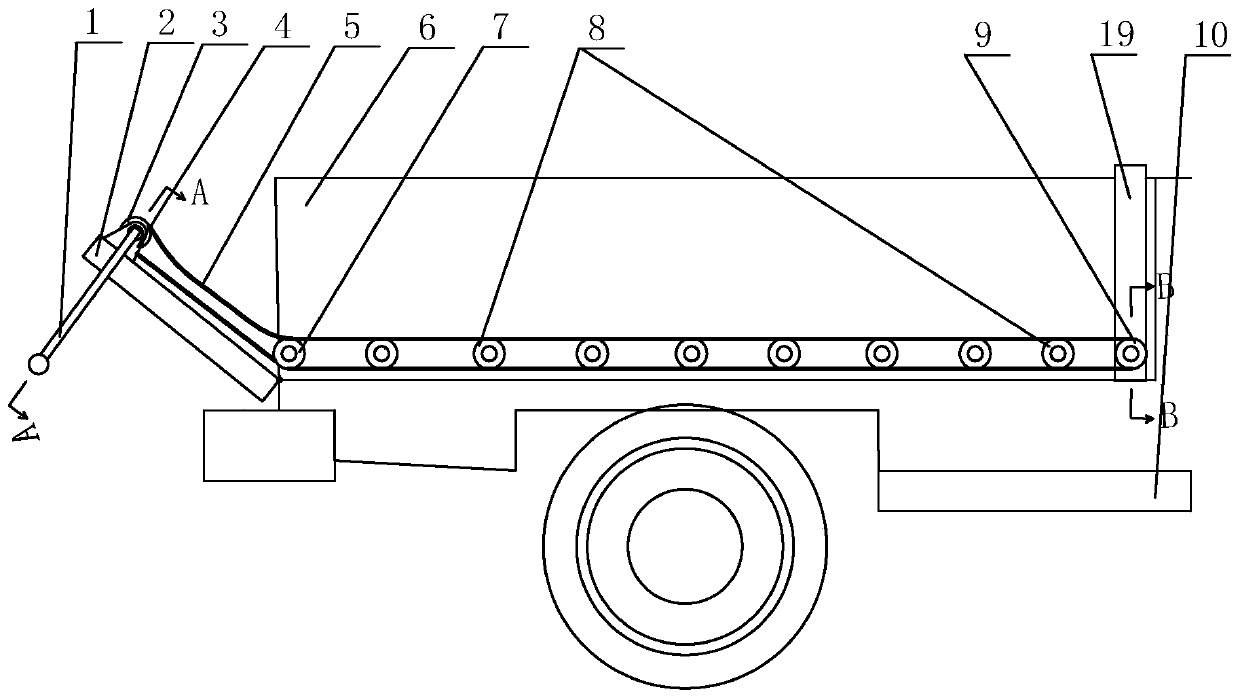

[0037] Such as Figure 1-Figure 4 As shown, the light truck auxiliary unloading device of the present invention,

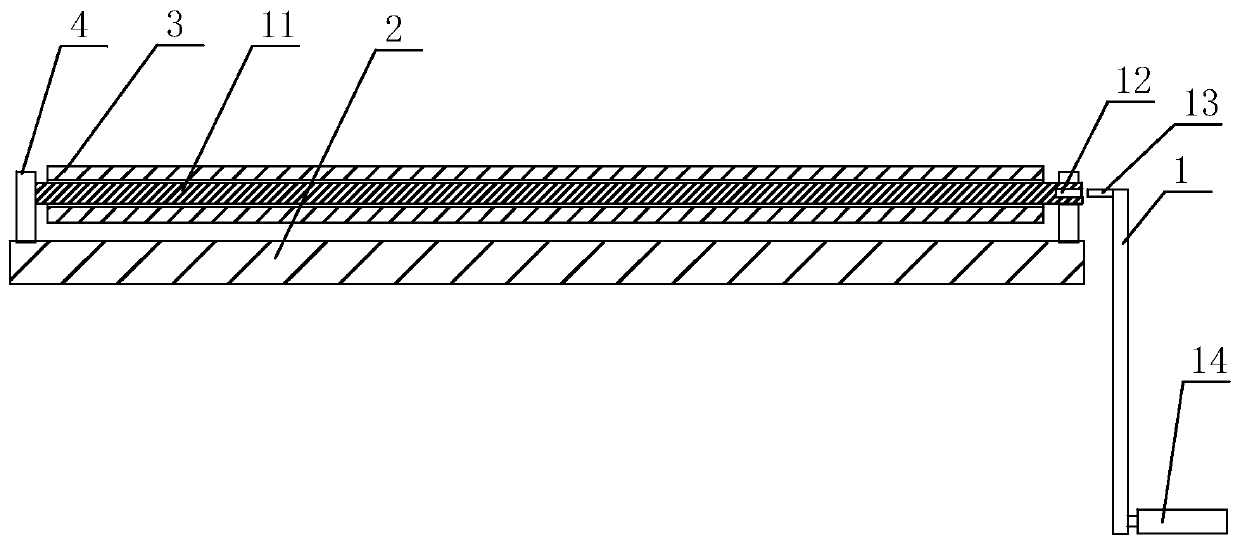

[0038] Including the conveying mechanism, the conveying mechanism includes the driving roller 3, the driven roller 9, the supporting roller 8, the reversing roller 7 and the conveyor belt 5. The rotating shaft 11 of the driving roller 3 is installed on the axle seat 4, and the axle seat 4 is fixed on the tail of the car body On the upper part of the inner wall of the door 2, a driven roller 9 is provided at the front end of the vehicle body, a reversing roller 7 is provided at the rear end of the vehicle body, and a number of support rollers 8 are provided between the reversing roller 7 and the driven roller 9, between the driving roller 3 and the driven roller A conveyor belt 5 is wound on the moving roller 9, and the reversing roller 7 and the supporting roller 8 are in a closed space formed by the conveyor belt 5;

[0039] It includes a transmission mechanism. The t...

Embodiment 2

[0046] Such as Figure 5-Figure 12 As shown, as another preferred solution, the transmission mechanism includes a runner 20. A groove is provided on the side of the runner 20. The runner 20 is in the shape of a pulley. A square rod 13 is fixed at the axis of the end face of the runner 20. The holes 12 are matched, and the rope 26 is wrapped around the groove of the runner 20. Pulling the rope 26 can make the runner 20 rotate, the runner 20 drives the driving roller 3 to rotate, and the driving roller 3 drives the conveyor belt 5 to rotate, thereby unloading the material. The support roller 8 plays the role of supporting the conveyor belt 5, preventing the conveyor belt 5 from being crushed by the material, which cannot be supported by manpower during unloading, and even causing the conveyor belt 5 to wear.

[0047] A fixing device is included. The fixing device includes a positioning rod 23, the lower end of the positioning rod 23 is sharp, and the upper end of the positioning r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com