Clamping force detection system and method for seedling clamping manipulator

A technology for detection systems and manipulators, applied in force/torque/power measuring instruments, measurement of properties and forces using piezoelectric devices, and measurement devices, can solve problems such as inaccurate detection systems and reduced productivity, and achieve cost reduction, Avoid loss, non-destructive clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

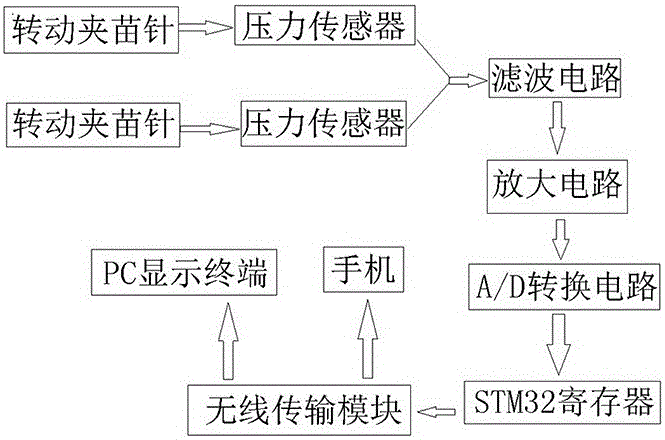

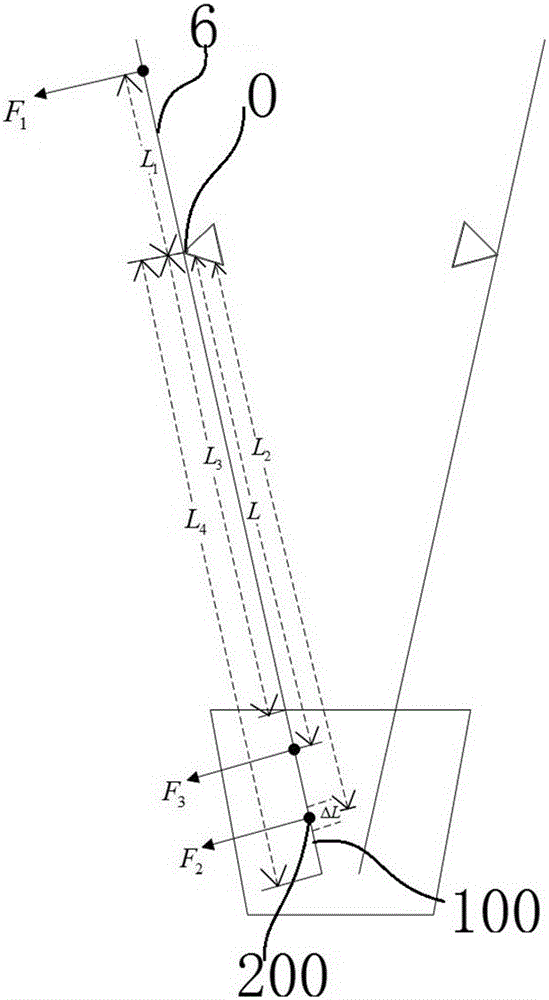

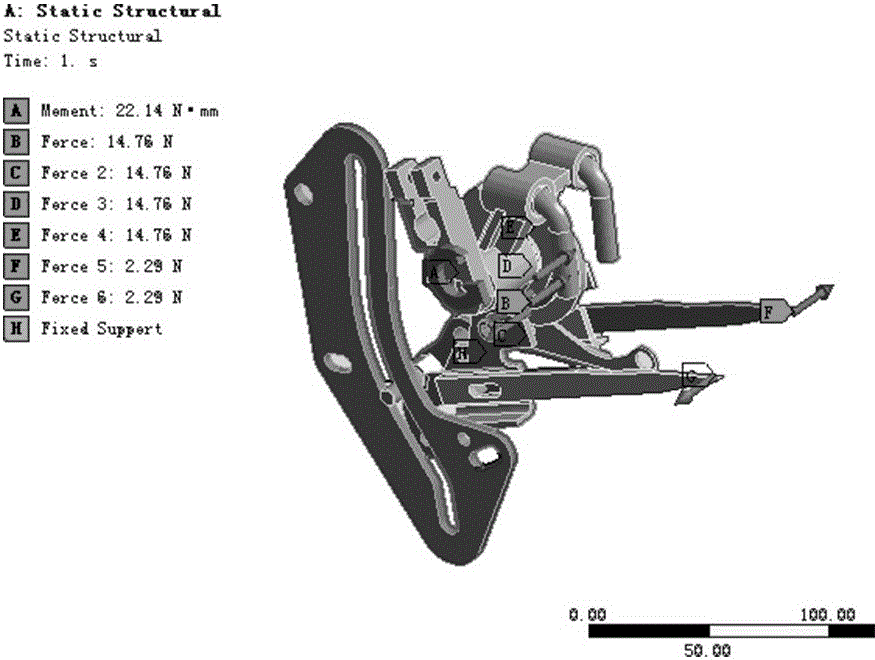

[0027] In order to better illustrate the clamping force detection system and detection method of the seedling clamping manipulator provided by the present invention, a seedling clamping manipulator is firstly introduced, which includes a bracket, and the front end of the bracket is provided with two shaft sleeves arranged in parallel. Equipped with supporting rotating shafts, each supporting rotating shaft 1 is respectively fixed with a rotating seedling clamping needle 6, and the rotating seedling clamping needle 6 is fixed to the supporting rotating shaft 1. The bottoms of the two rotating seedling clamping needles 6 respectively have clamping stressed sections, and the clamping stressed sections are located below the supporting rotating shaft 1, and the two rotating clamping seedling needles rotate around the supporting rotating shaft, and the clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com