Thermostatic valve having a sleeve

A thermostatic valve and sleeve technology, applied in the field of thermostatic valves, can solve problems such as stress application and valve failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

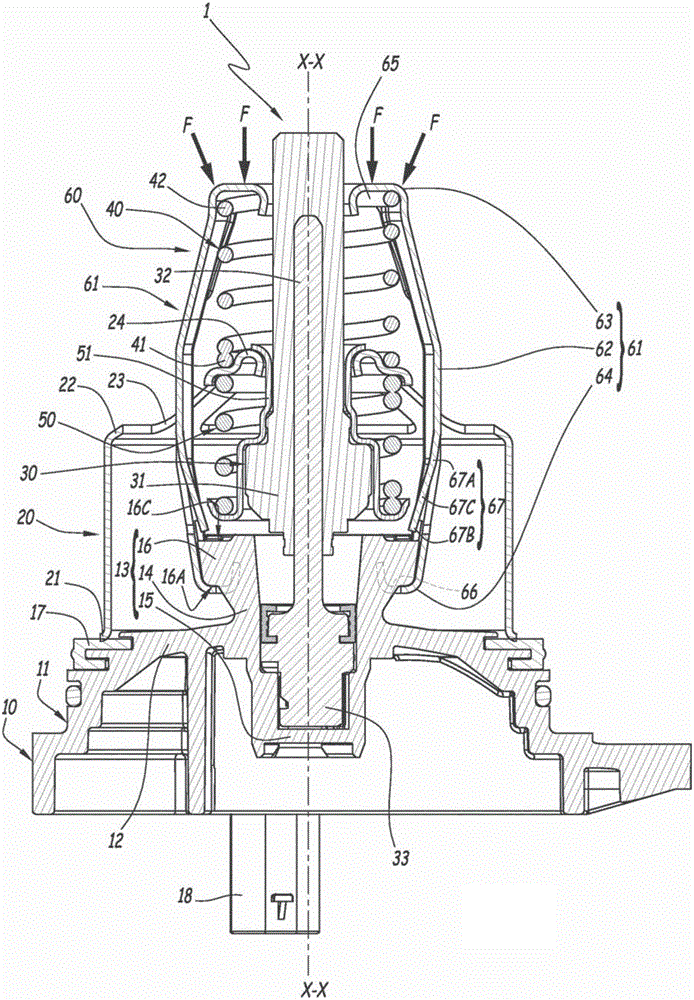

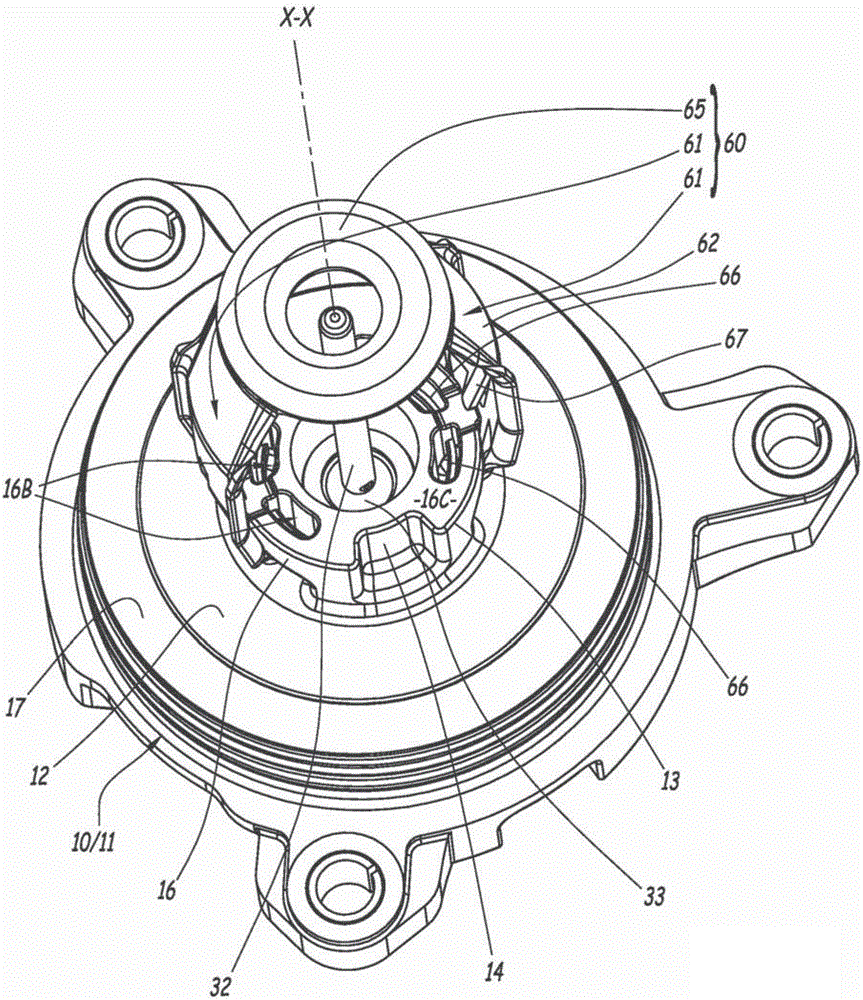

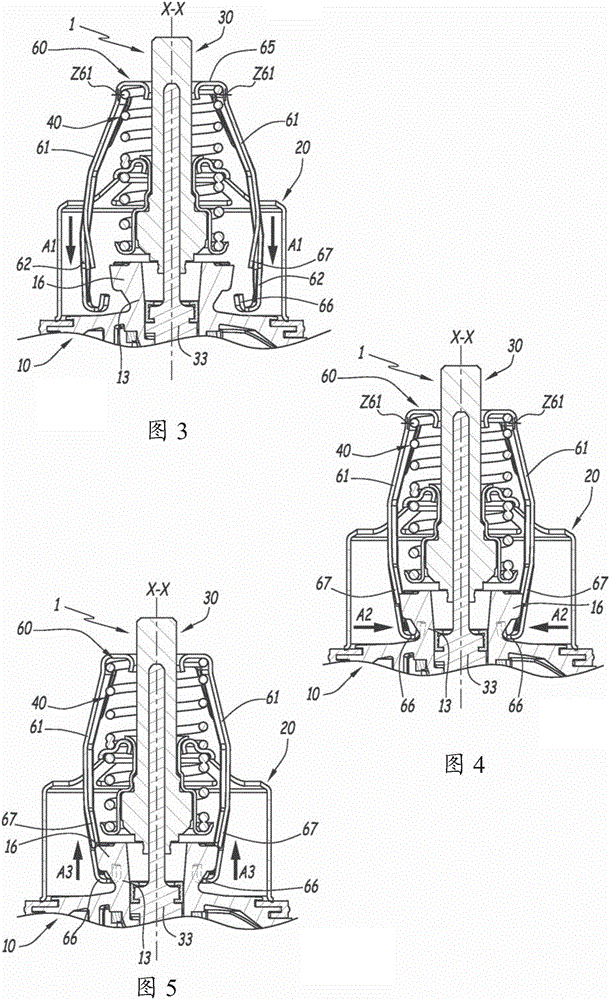

[0013] figure 1 to 5 show a valve 1 suitable for controlling the circulation of a fluid. For example, valve 1 is used in the cooling circuit of a heat engine of a vehicle.

[0014] The valve 1 comprises a housing 10 in which the fluid mentioned above circulates. The housing 10 is in particular made of plastic, for example by moulding. In the example considered here, as figure 1 and 2 As clearly shown, the housing 10 comprises a main body 11 comprising a closed wall 12 separating the inside and the outside of the main body 11, the fluid regulated by the valve only in the Medial flow. Such as figure 1 Clearly shown, the closure wall 12 extends transversely to the geometrical axis X-X, which belongs to figure 1 , and for convenience the rest of the description is adjusted with respect to the geometric axis X-X, which is considered to extend along the vertical inner side of the main body 11, which is the inner side of the closed wall 12 in figure 1 To the side turned up in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com