Thermostatic valve with sleeve

A thermostatic valve and sleeve technology, applied in the field of thermostatic valves, can solve problems such as stress application and valve failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

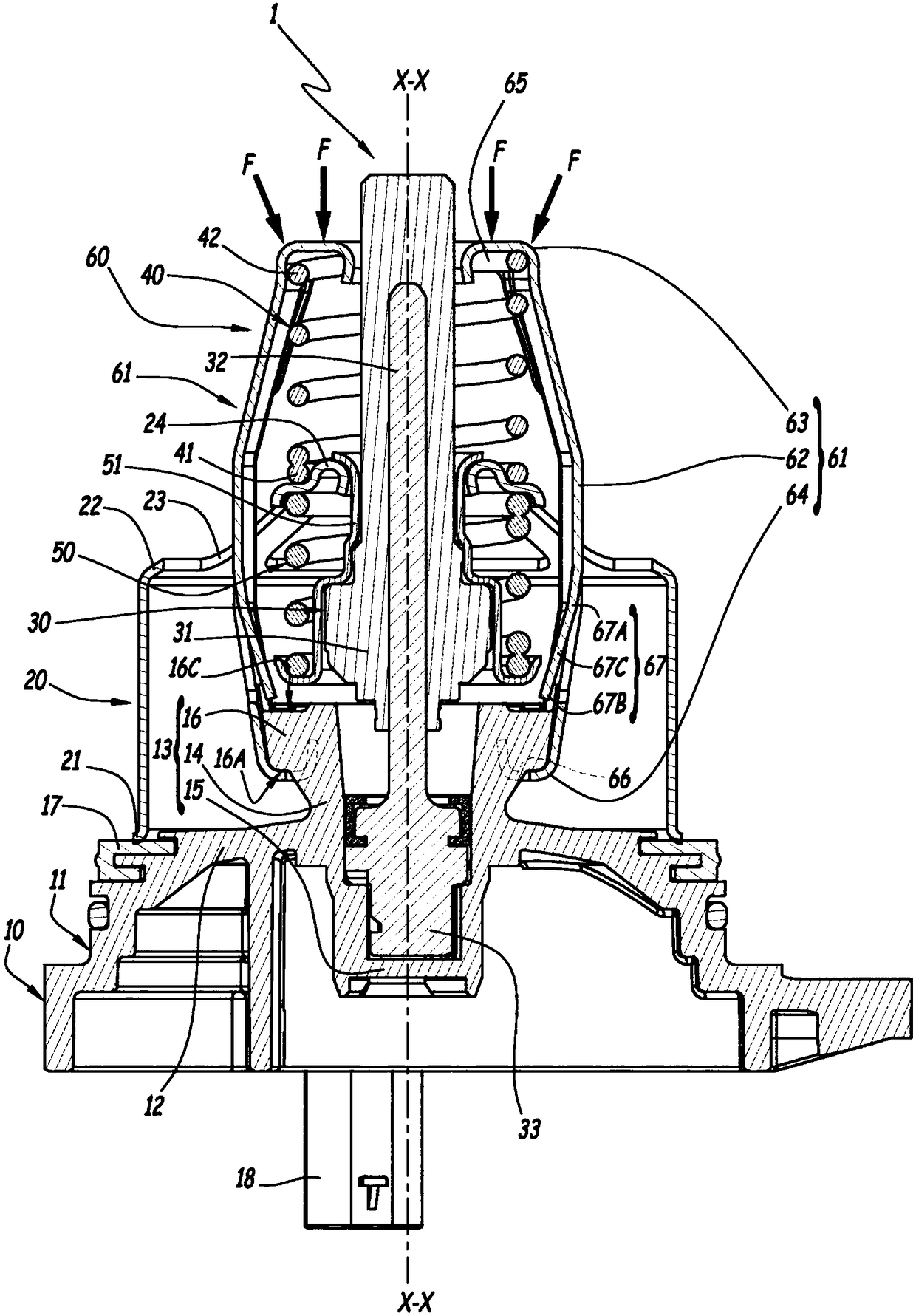

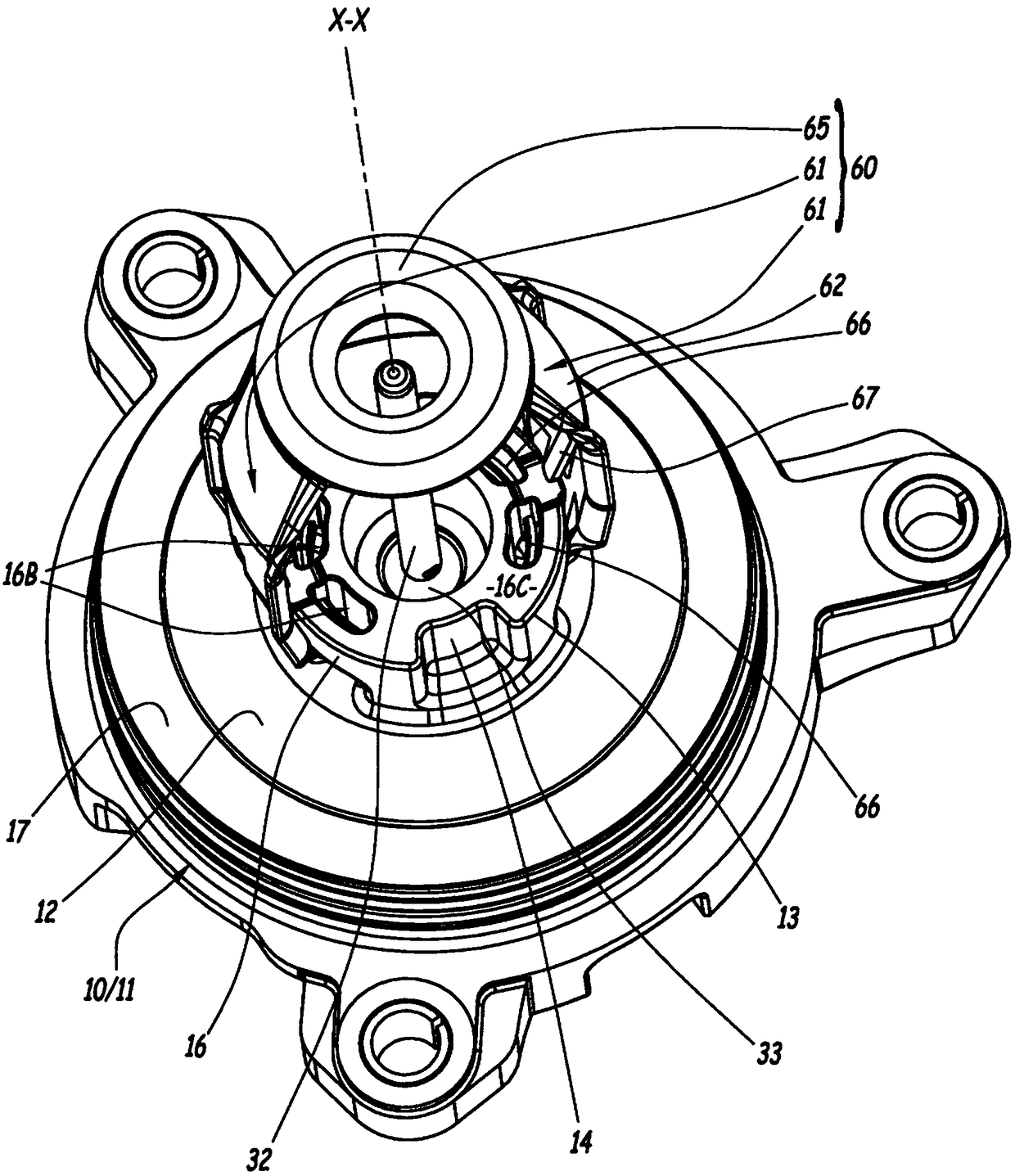

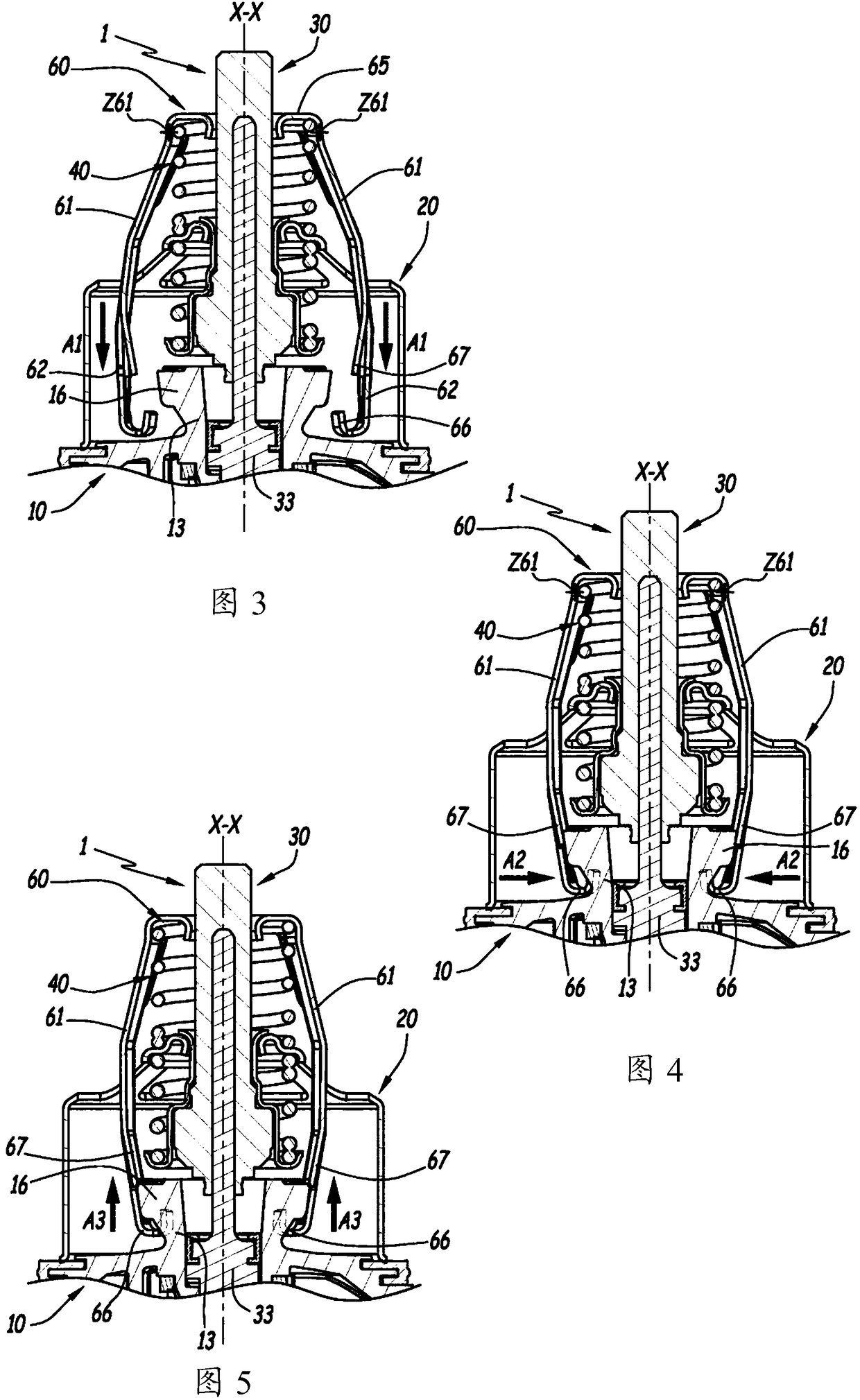

[0034] Figure 1 to 5 A valve 1 suitable for controlling the circulation of fluid is shown. For example, the valve 1 is used for the cooling cycle of the heat engine of the vehicle.

[0035] The valve 1 includes a housing 10 in which the fluid mentioned above circulates. The housing 10 is especially made of plastic, for example by moulding. In the embodiment considered here, such as figure 1 with 2 It is clearly shown that the housing 10 includes a main body 11, and the main body 11 includes a closed wall 12 separating the inner and outer sides of the main body 11. Except in the case of abnormal leakage, the fluid regulated by the valve is only in the closed wall 12 Flow inside. Such as figure 1 It is clearly shown that the closing wall 12 extends transversely to the geometric axis X-X, which belongs to figure 1 For convenience, adjust the rest of the description relative to the geometric axis X-X, so that the axis X-X extends along the vertical inner side of the main body 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com