A self-expanding sealer

A self-expanding and sealing device technology, which is applied in sealing/packing, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of easy sand jamming, poor reliability, and early setting, so as to avoid sand jamming , high reliability, avoid falling off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

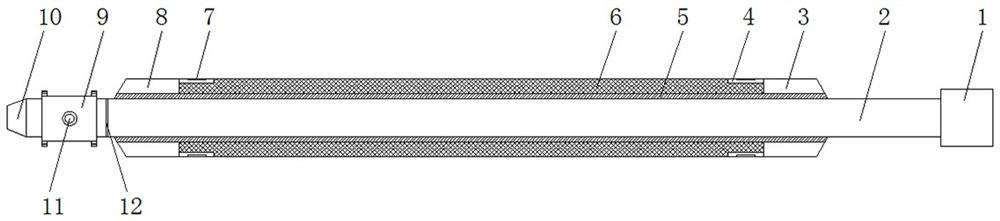

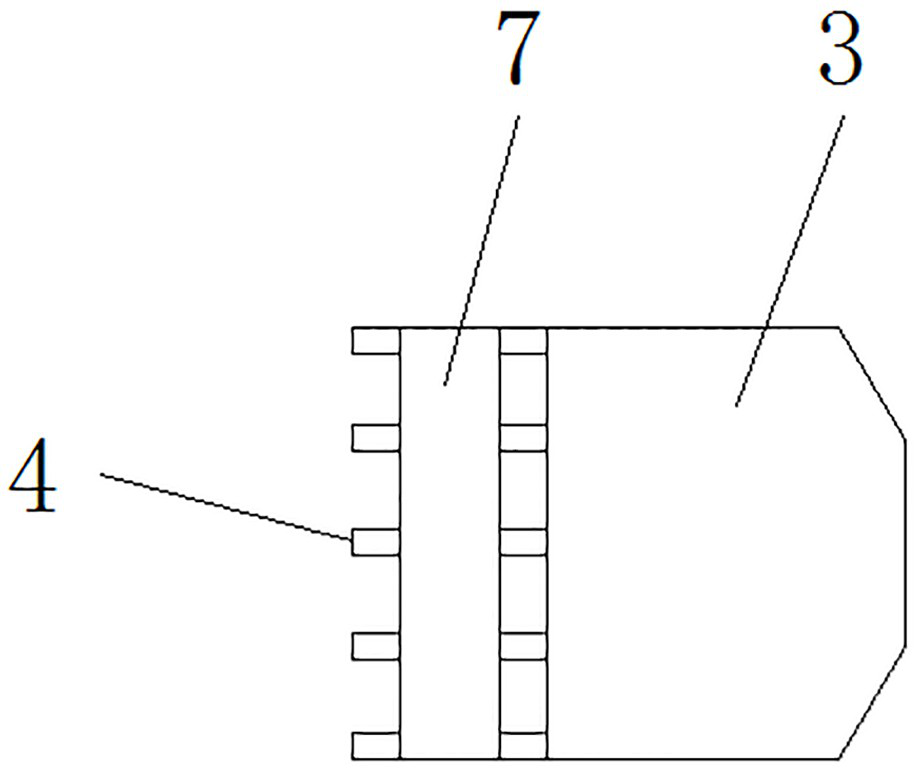

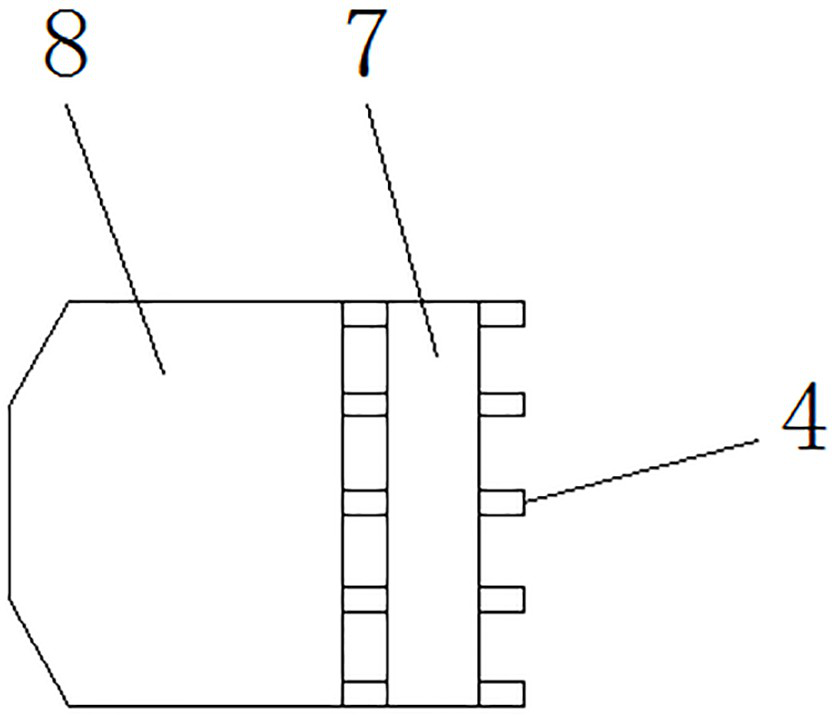

[0021] see Figure 1-3 , an embodiment provided by the present invention: a self-expanding sealer, including a central tube 2, an upper fixing collar 3, a self-expanding rubber tube 6, a lower fixing collar 8 and a valve collar 9, the top end of the central tube 2 A coupling 1 is installed, and the outer surface of the middle position of the center pipe 2 is wrapped with a glass fiber heat insulation layer 5, and the outside of the glass fiber heat insulation layer 5 is sleeved with a self-expanding rubber cylinder 6, and the self-expanding rubber cylinder 6 is adopted It is a composite material synthesized by fluororubber and fluorosilicone rubber, and the hydrophilic and water-absorbing gene molecules are introduced into the self-expanding rubber cylinder 6 by using chemical branch method and physical blending method. The glass fiber heat insulation layer at the upper end of the self-expanding rubber cylinder 6 The outer side of 5 is equipped with an upper fixing hoop 3, and...

Embodiment 2

[0030] see Figure 1-3 , an embodiment provided by the present invention: a self-expanding sealer, including a central tube 2, an upper fixing collar 3, a self-expanding rubber tube 6, a lower fixing collar 8 and a valve collar 9, the top end of the central tube 2 A coupling 1 is installed, and the outer surface of the middle position of the center pipe 2 is wrapped with a glass fiber heat insulation layer 5, and the outside of the glass fiber heat insulation layer 5 is sleeved with a self-expanding rubber cylinder 6, and the self-expanding rubber cylinder 6 is adopted It is a composite material synthesized by fluororubber and fluorosilicone rubber, and the hydrophilic and water-absorbing gene molecules are introduced into the self-expanding rubber cylinder 6 by using chemical branch method and physical blending method. The glass fiber heat insulation layer at the upper end of the self-expanding rubber cylinder 6 The outer side of 5 is equipped with an upper fixing hoop 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com