Plugging machine in self-expanding oil tube

A self-expanding, oil pipe technology, applied in the field of plugging devices, can solve the problems of time-consuming and laborious, no blowout prevention facilities, waste of resources, etc., and achieve good sealing effect, excellent water retention performance, and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

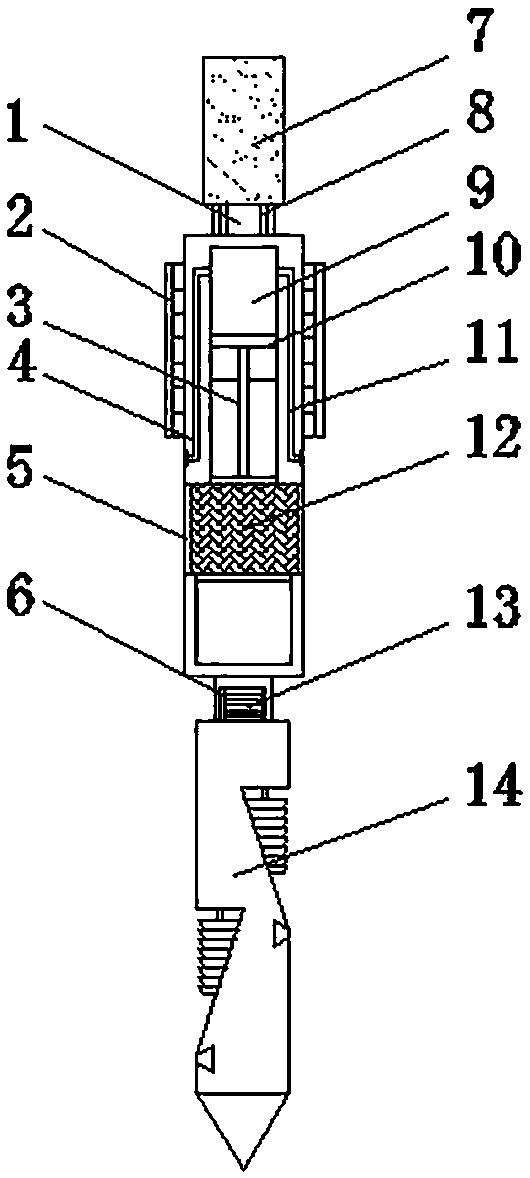

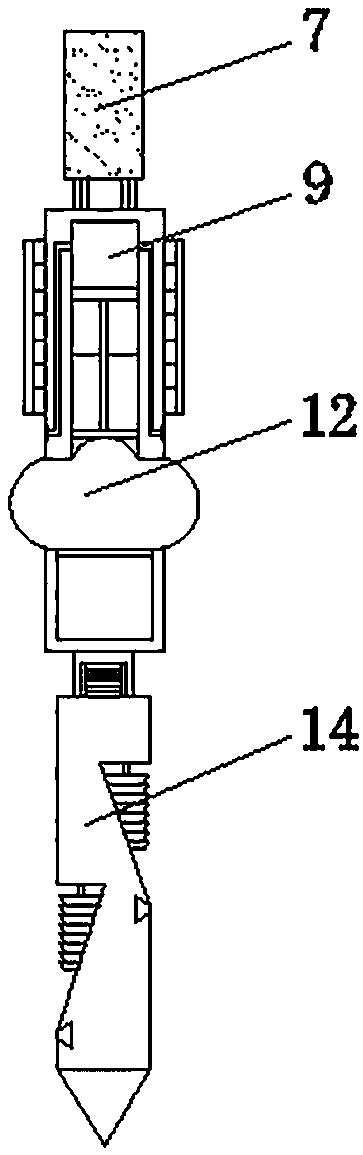

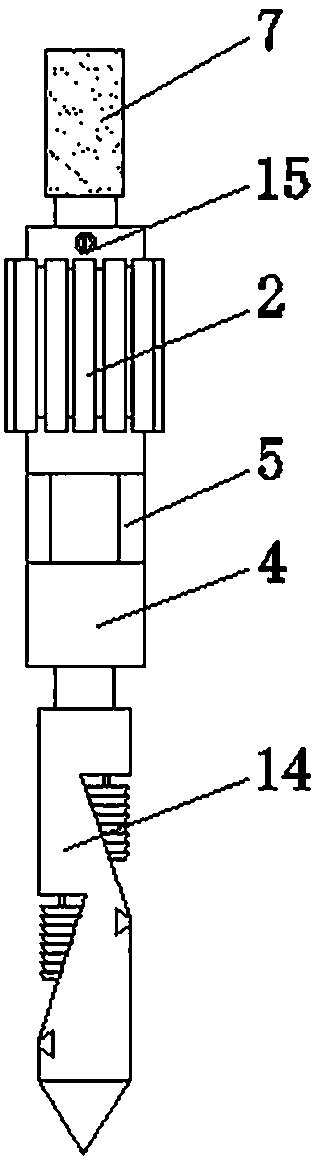

Embodiment 1

[0021] see Figure 1-3 , an embodiment provided by the present invention: a plugging device in a self-expanding oil pipe, including a one-way slip 2, a main body center pipe 4 and a weighting rod 7, the top of the main body center pipe 4 is fixed with a weighting rod 7, and the weighting rod The bottom end of 7 is fixed with clamping block 1, and the top of main body central tube 4 is provided with the card groove 8 that cooperates with clamping block 1, is convenient to replace the weighting bar 7 of corresponding specification, and the bottom end of main body central tube 4 is fixed with guide head 14. There is a reserved groove 6 inside the bottom end of the main body central tube 4, and an internal thread is provided on the inner wall of the reserved groove 6, and an external thread that cooperates with the internal thread is provided on the outer wall of the reserved block 13, which is convenient for guiding For the replacement of the head 14, the top of the guide head 14...

Embodiment 2

[0028] see Figure 1-3 , an embodiment provided by the present invention: a plugging device in a self-expanding oil pipe, including a one-way slip 2, a main body center pipe 4 and a weighting rod 7, the top of the main body center pipe 4 is fixed with a weighting rod 7, and the weighting rod The bottom end of 7 is fixed with clamping block 1, and the top of main body central tube 4 is provided with the card groove 8 that cooperates with clamping block 1, is convenient to replace the weighting bar 7 of corresponding specification, and the bottom end of main body central tube 4 is fixed with guide head 14. There is a reserved groove 6 inside the bottom end of the main body central tube 4, and an internal thread is provided on the inner wall of the reserved groove 6, and an external thread that cooperates with the internal thread is provided on the outer wall of the reserved block 13, which is convenient for guiding For the replacement of the head 14, the top of the guide head 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com