Double handle coaxial temperature control valve core

A temperature control valve, coaxial technology, applied in temperature control, multi-way valve, valve device, etc., can solve the problems of not conforming to the user's usage habits, unstable outlet water temperature, etc., and achieve the effect of accurate outlet water temperature and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below through the accompanying drawings and specific embodiments.

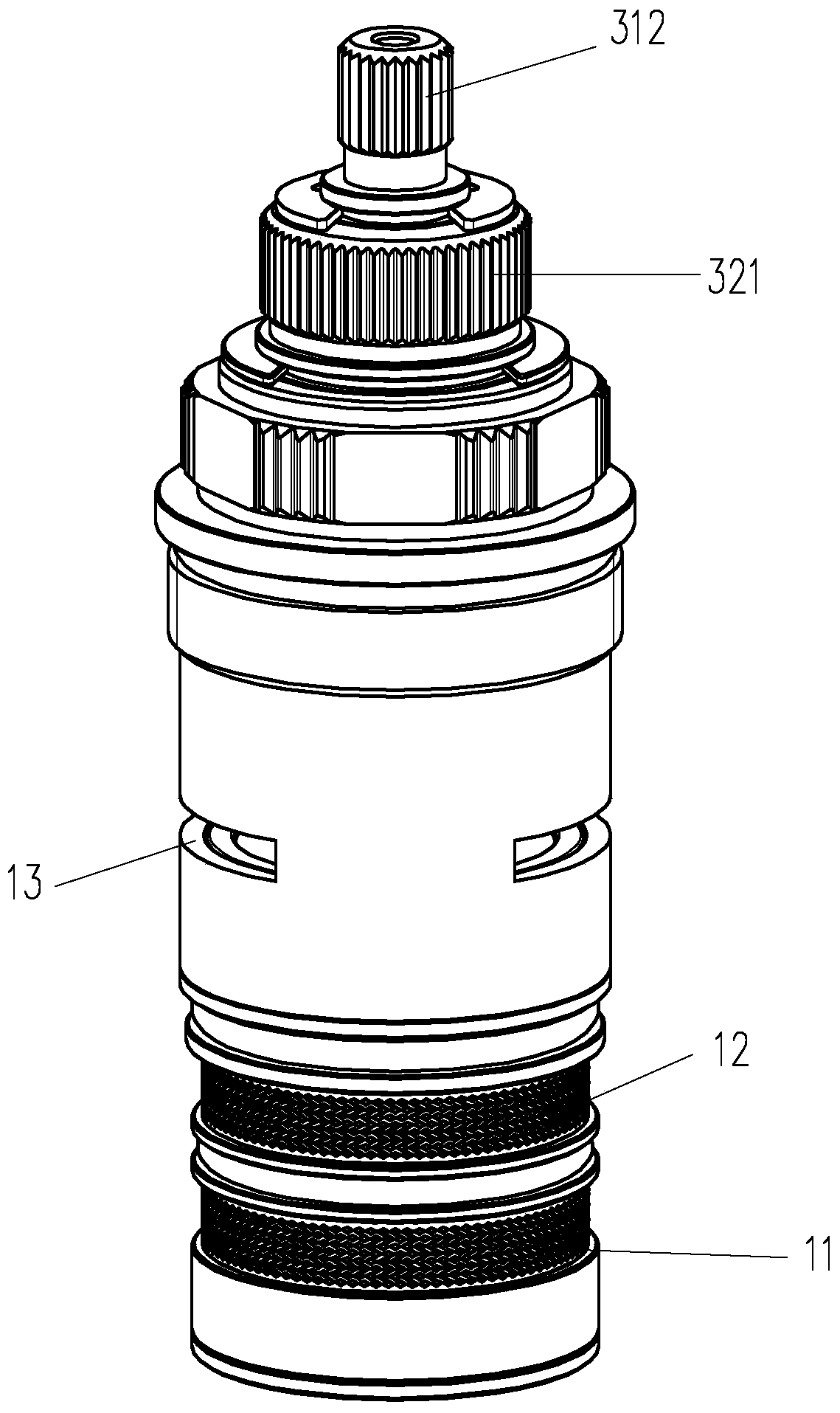

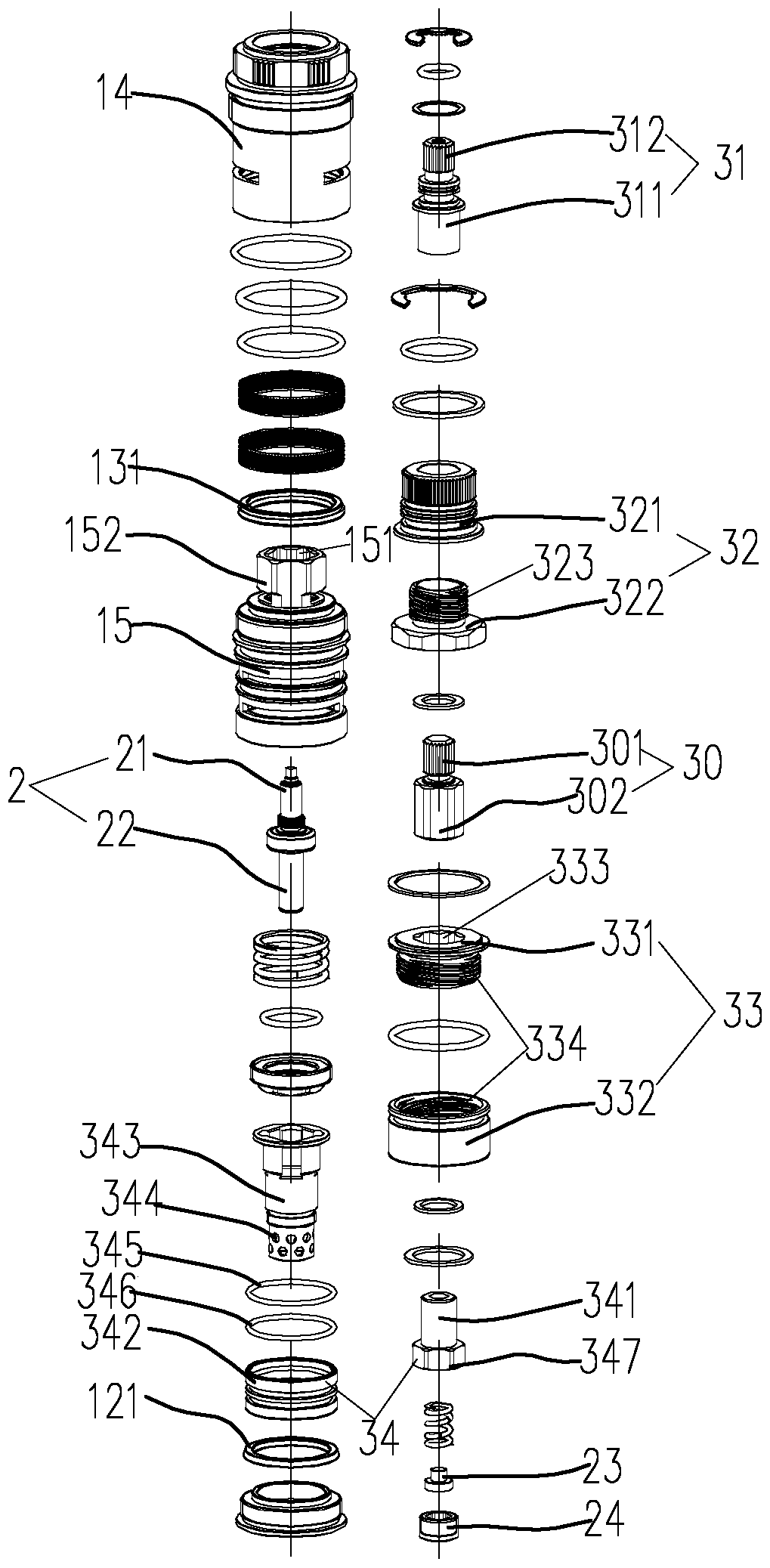

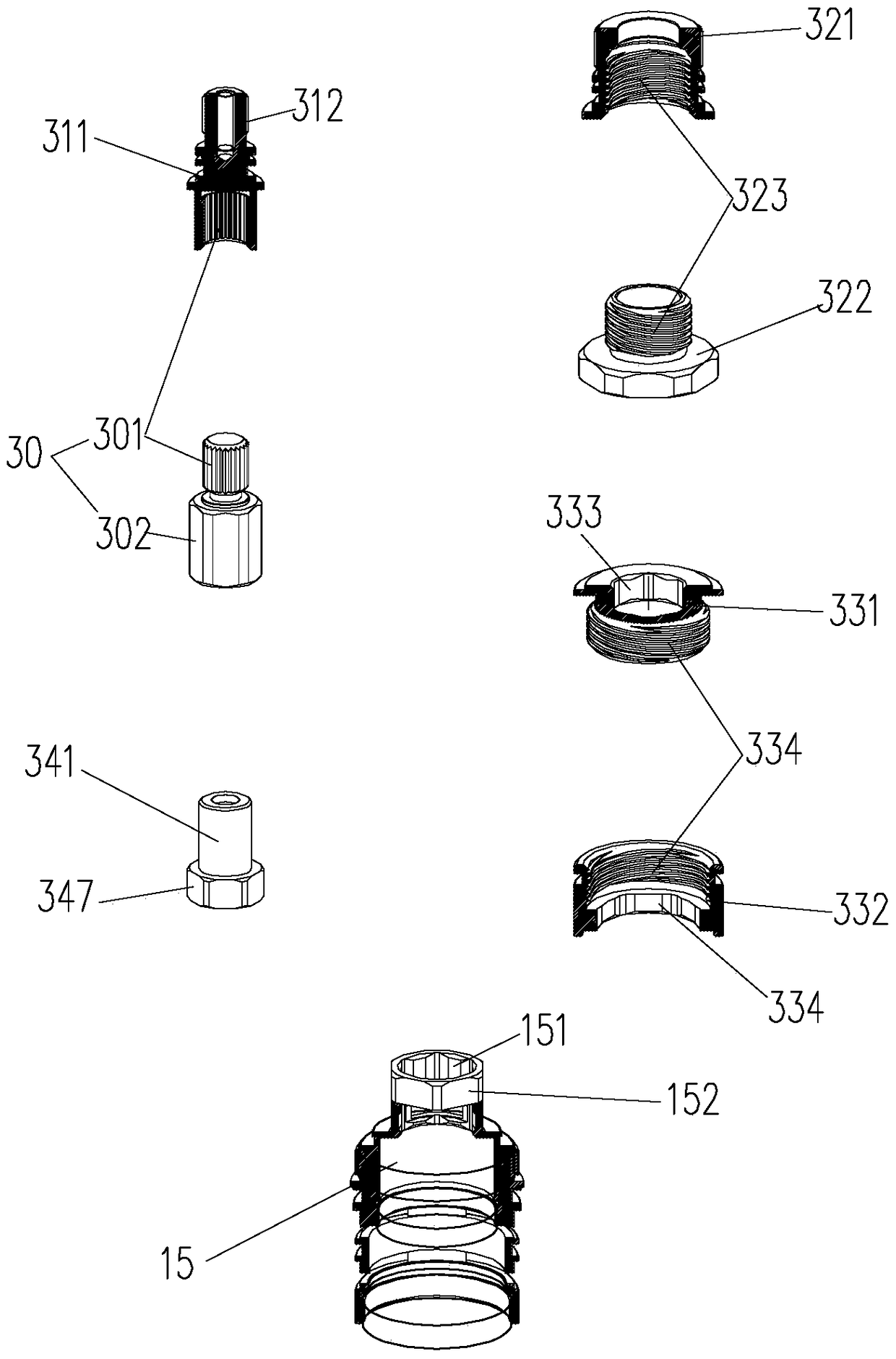

[0034] refer to Figure 1-7 , a dual-handle coaxial temperature control spool, including:

[0035] A valve body 1, which has a cold water inlet 11, a hot water inlet 12 and a mixed water outlet 13; the valve body 1 includes an outer shell 14 and a lower shell 15, and the outer peripheral surface of the lower shell 15 is from top to bottom The cold water inlet 11 and the hot water inlet 12 are arranged coaxially on the lower side; the mixed water outlet 13 is arranged on the outer periphery of the outer casing 14; the top end of the lower casing 15 extends into the upper casing 14 and securely connect it.

[0036] A thermosensitive element 2 with a temperature sensing end 21 and a telescopic end 22, the temperature sensing end 21 is close to the mixing water outlet 13, used to sense the water outlet temperature information of the mixing water outlet 13, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com