Dried bean curd stewing and boiling box

A technology of dried tofu and stewing, which is applied in the field of stewing equipment, can solve the problems of low production efficiency, high labor intensity, uneven stewing, etc., and achieve the effects of uniform rotation speed and stirring speed, full turning, and comprehensive contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

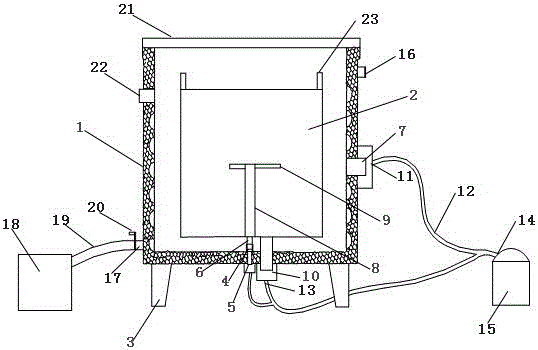

[0019] Basic as attached figure 1 Shown:

[0020] Dried tofu marinated cooking box, including a box body and legs 3, the box body is composed of an outer box 1 and an inner box 2, the inner box 2 is made of metal mesh, so that the marinade can penetrate into the inner box from the outer box; The inner box 2 is arranged inside the outer box 1, and the bottom of the outer box 1 is welded with a shaft sleeve 4, the shaft sleeve 4 is a cavity structure, and the bottom of the cavity structure is provided with a first steam inlet 5 , the bottom of the inner box 2 is welded with a rotating shaft 6, the rotating shaft 6 is sleeved in the rotating shaft sleeve 4, the inner box 1 and the outer box 2 are connected through the rotating shaft 6, and the rotating shaft can move up and down in the rotating shaft sleeve. Relative to the rotation of the outer box.

[0021] The side wall of the outer box 1 is provided with a second steam inlet 7, and the inner box 2 is provided with a stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com