Tea leaf steaming device

A greening device and tea technology are applied in the direction of tea treatment before extraction, etc., which can solve the problems of poor tea quality, uneven temperature, insufficient tea stirring, etc., and achieve the effects of high greening efficiency, uniform greening temperature, and improved greening efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

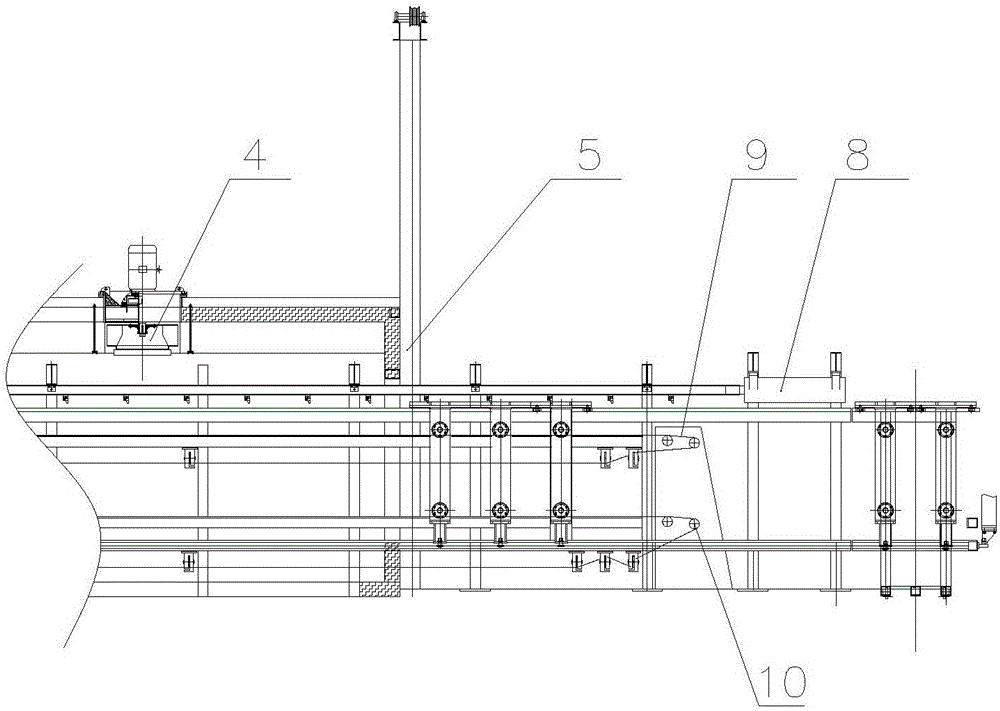

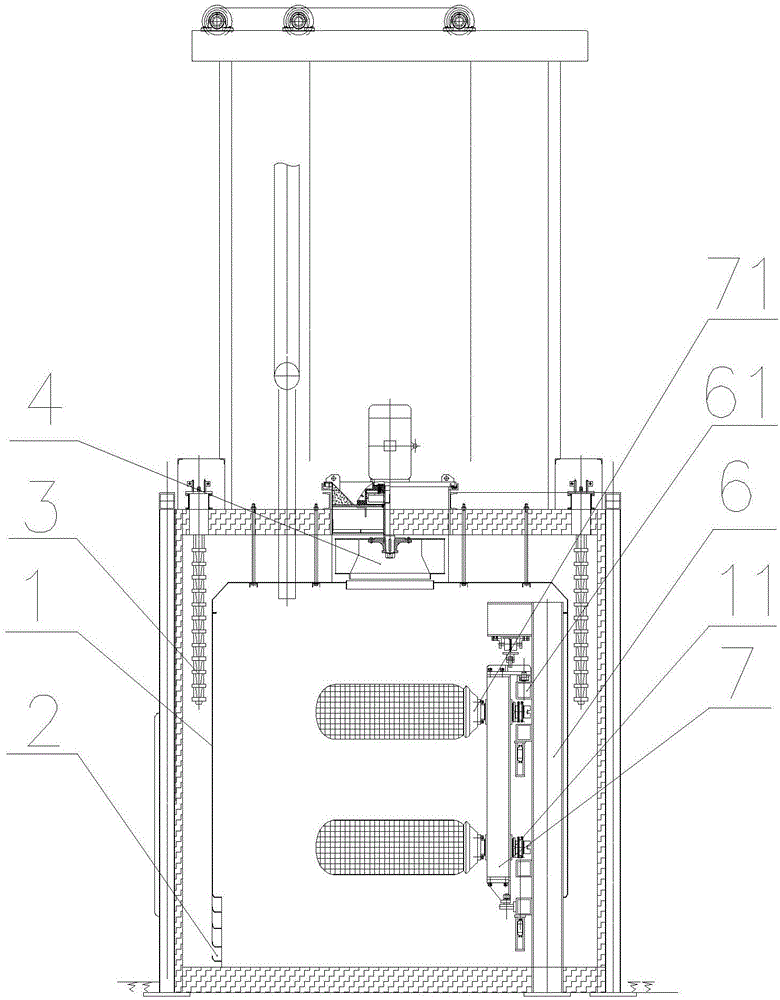

[0025] see Figure 1 to Figure 4 It is a tea greening device, which includes a heating furnace. A diversion layer 1 is arranged in the heating furnace. The diversion layer 1 divides the hearth of the heating furnace into an outer zone and an inner zone. The longitudinal ends of the outer zone are sealed. Furnace doors 5 driven by air cylinders are arranged at both longitudinal ends of the inner zone, and the lower part of the guide layer 1 is provided with a guide channel 2 to connect the outer zone and the inner zone, and the upper part of the outer zone is provided with an electric heater 3, so The upper part of the diversion layer 1 is provided with a circulating fan 4, which is used to blow the hot air in the outer zone into the inner zone, and the hot air in the inner zone flows into the outer zone of the heating furnace through the diversion channel 2, forming a circulation heating channel, A fixed seat 6 is arranged longitudinally along the heating furnace in the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com