Counterweight module system for quick deepening of marine towing rope

A modular system and towline technology, which is applied to underwater operation equipment, transportation and packaging, ships, etc., can solve problems such as high speed compatibility requirements, inconsistent towline formation, front-to-back drop, etc., and achieve the goal of reducing installation and disassembly time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments listed in the present invention are only used to help understand the present invention, and should not be interpreted as limiting the protection scope of the present invention. For those of ordinary skill in the art, they can also Improvements and modifications are made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

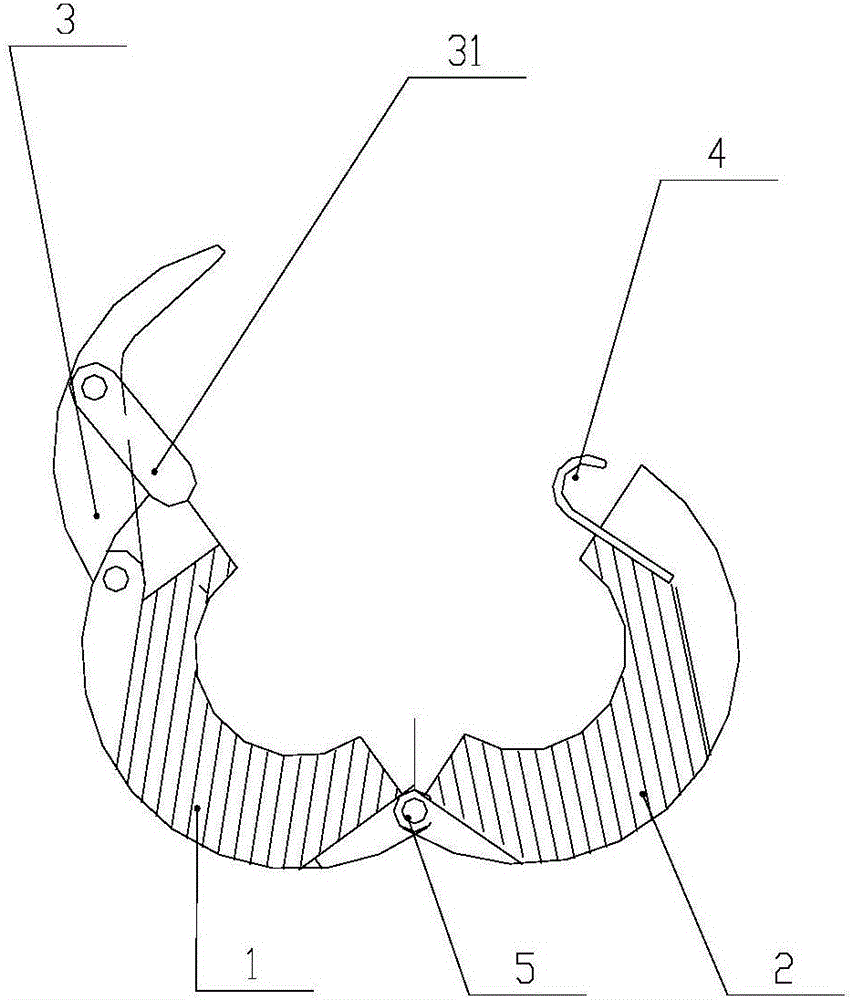

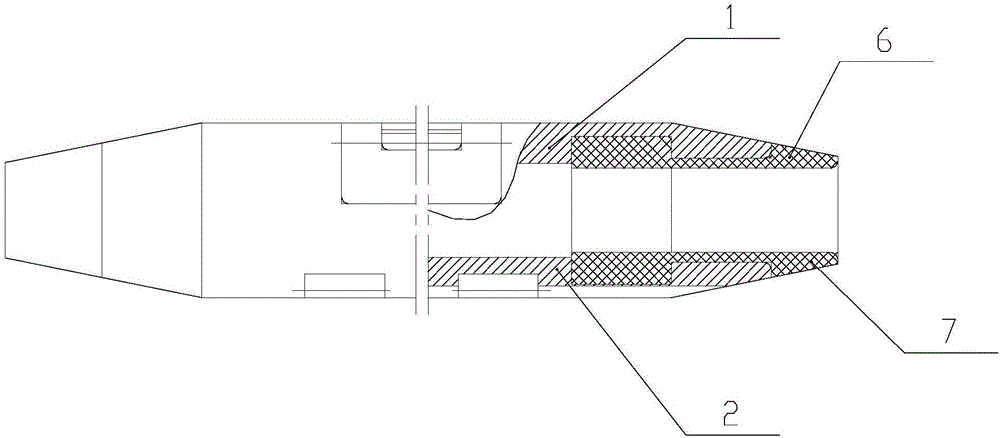

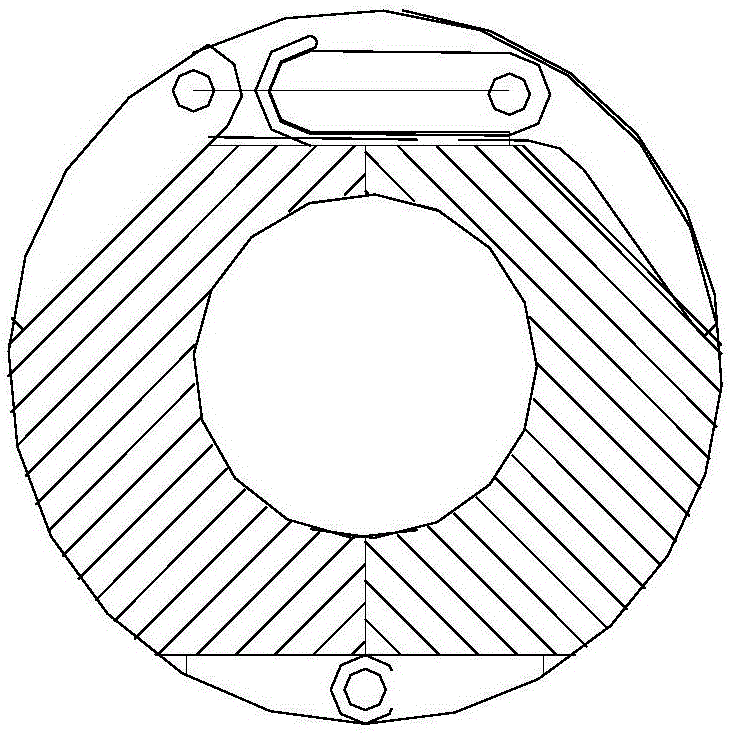

[0014] Such as figure 1 and figure 2 As shown, the present invention includes several detachable counterweight module units fixedly installed on the tow cable at equal intervals. As an optimal embodiment of the counterweight module end, the counterweight module unit includes a first clamping block 1, a second clamping block 2, a rotating buckle 3, a fixing buckle 4, a pin shaft 5, a first protective sleeve 6, a second Two protective sleeves 7; the first clamping block 1 and the second clamping block 2 are made of stainless steel, fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com