Lifting level meter maintenance device

A technology for overhauling device and material level gauge, applied in the direction of lifting device, lifting frame, etc., can solve the problems of complex structure, inconvenient use, large space occupation, etc., and achieve the effects of good safety, increased stability, and easy movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

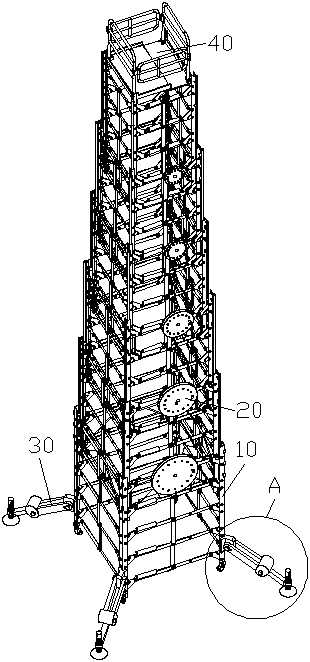

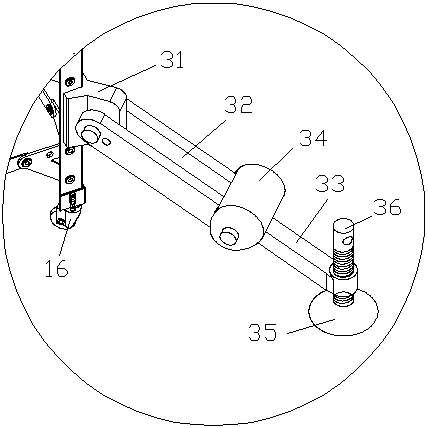

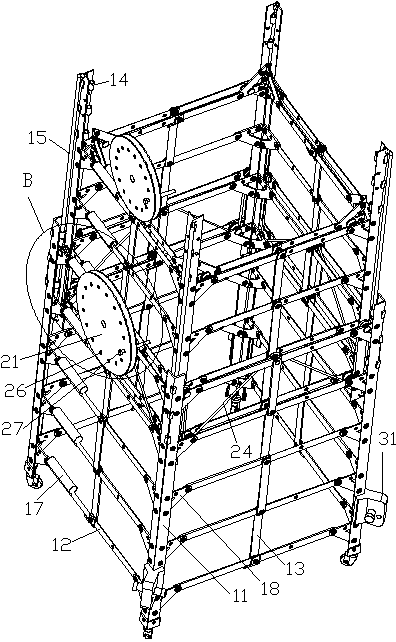

[0030] refer to Figure 1 to Figure 6

[0031] A lift-type material level meter maintenance device, comprising more than two lift frames 10 nested sequentially from the outside to the inside, a drive mechanism 20 for lifting the lift frame located on the inner side is arranged between two adjacent lift frames. The lower part of the lifting frame on the outside is provided with an auxiliary support positioning mechanism 30, so as to increase stability. A support platform 40 for personnel to stand is provided on the top of the innermost elevating frame for maintenance operations.

[0032] In this embodiment, the driving mechanism is a pulley mechanism composed of a pulley block and a winding rope. The drive mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com