Industrial sewing machine

A technology of industrial sewing machines and servo motors, applied in sewing machine components, program-controlled sewing machines, sewing machine control devices, etc., can solve problems such as wrinkling, inability to change at any time, and affecting sewing effects, etc. Improve sewing precision and quality, and improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the implementations shown in the drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structural changes made by these implementations Equivalent transformations or substitutions all fall within the protection scope of the present invention.

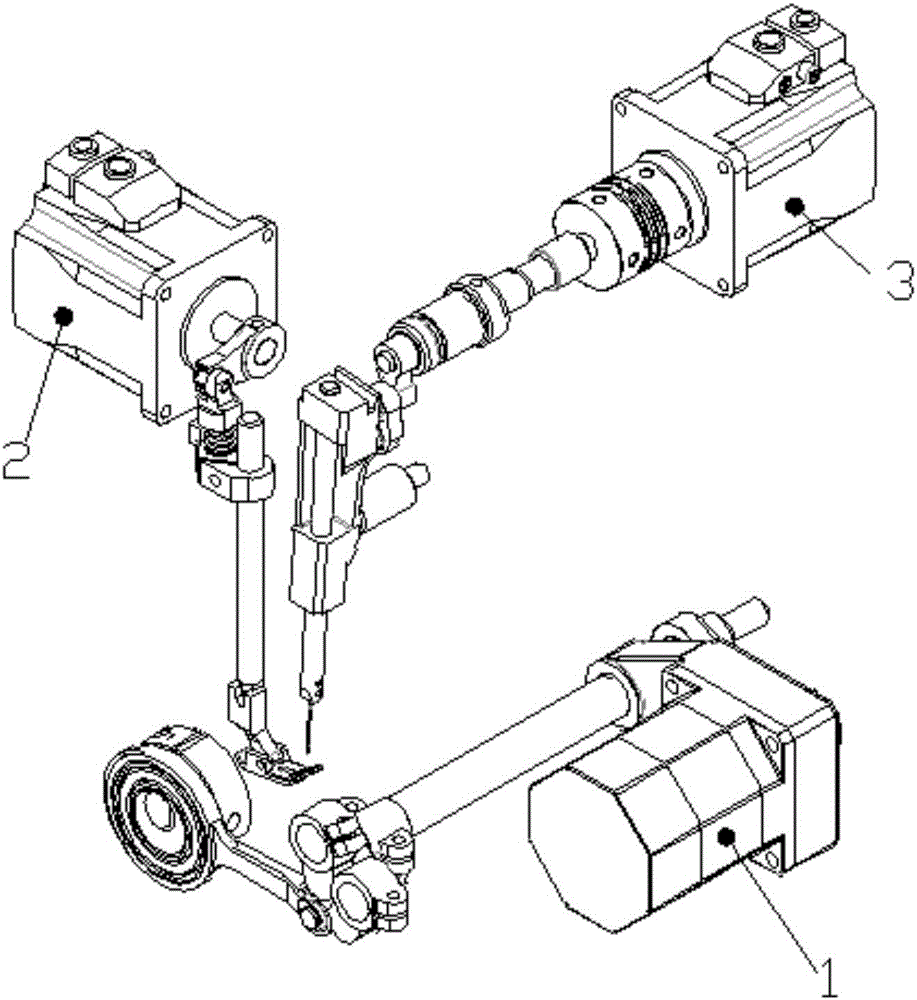

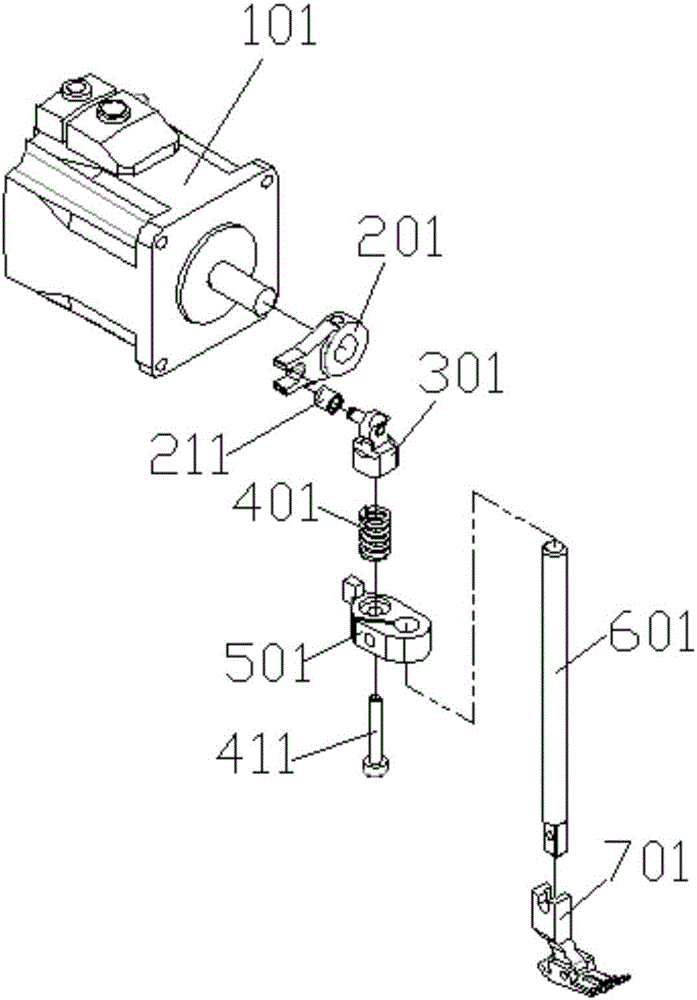

[0030] Such as figure 1 As shown, the industrial sewing machine of the present invention includes: a control device (not shown), an electronic stitch length control device 1 , an adaptive presser foot device 2 and a needle bar swing device 3 .

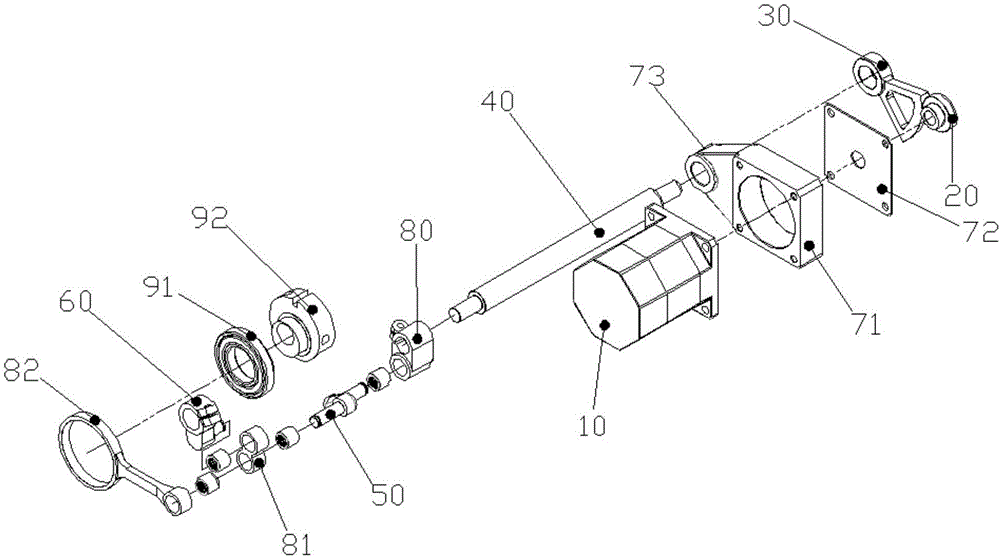

[0031] Such as figure 2 As shown, the electronic stitch length control device 1 includes: a first servo motor 10 , a driving gear 20 , a driven sector gear 30 , a transmission shaft 40 , a first crank 50 , and a feeding connecting rod 60 .

[0032] The control device controls the operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com