Suspension method and suspension arm assembly of bridge detection device

A bridge inspection and suspension arm technology, applied in bridge parts, bridges, bridge construction, etc., can solve the problems of high-altitude operation safety hazards, small contact area, etc., and achieve the effect of ensuring safety, increasing safety, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

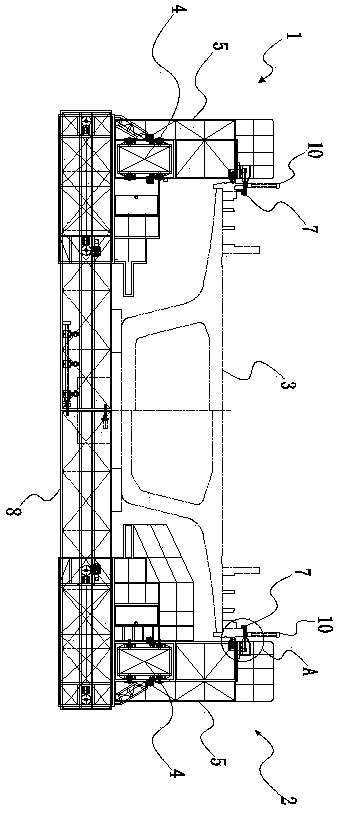

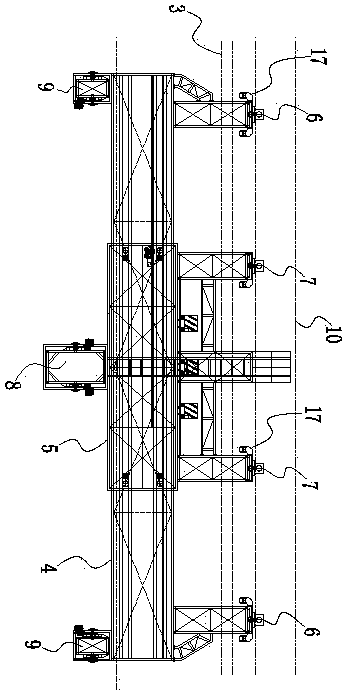

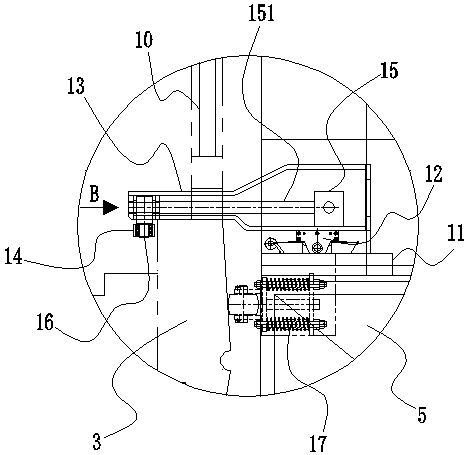

[0051] Example: such as figure 1 and figure 2As shown, the present invention first discloses a bridge detection device comprising left and right two bridge detection mechanisms, the left bridge detection mechanism 1 and the right bridge detection mechanism 2 both include a walking beam body 4 and a socket joint arranged along the length direction of the railway bridge 3 The detection beam body 5 on the walking beam body 4 is provided with a drive mechanism 1 between the walking beam body 4 and the detection beam body 5, and a suspension arm assembly 1 suspended on the railway bridge is provided on the top of the walking beam body 4 6. A suspension arm assembly 2 7 for hanging on the railway bridge is arranged on the top of the detection beam body 5. When any one of the walking beam body 4 and the detection beam body 5 is suspended and fixed on the railway bridge 3 , under the action of the driving mechanism 1, the other beam body can move along the length direction of the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com