UHPC-Ordinary Concrete Laminated Composite Bridge Deck Structure and Construction Method

A common concrete and concrete technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as stress concentration, large block size, fatigue damage of steel bridge deck welding, etc., achieve continuous shear force transmission, and eliminate local stress concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

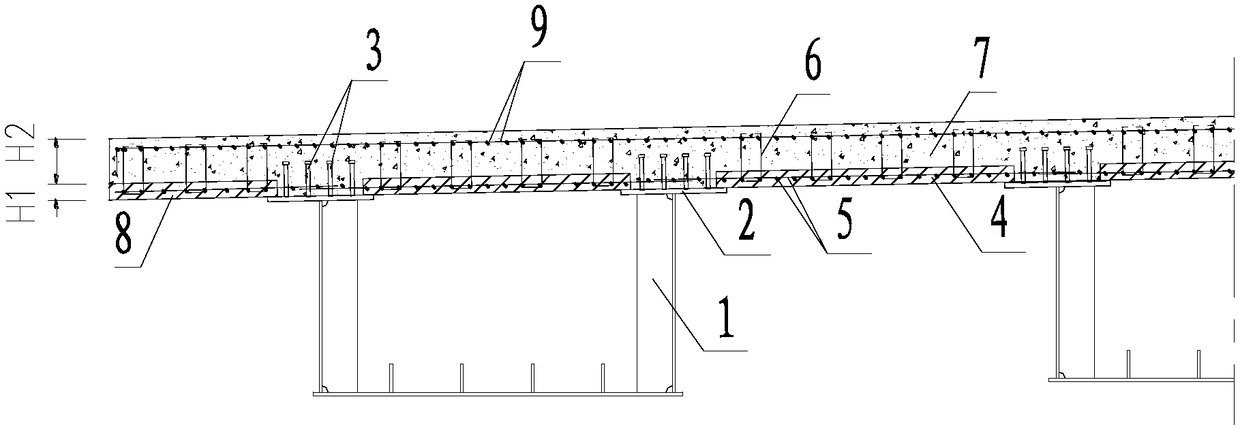

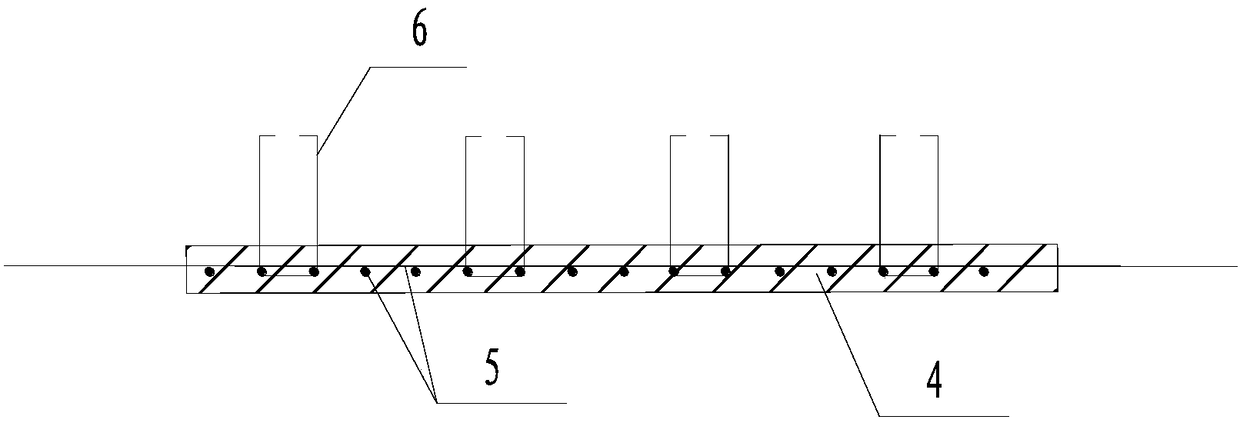

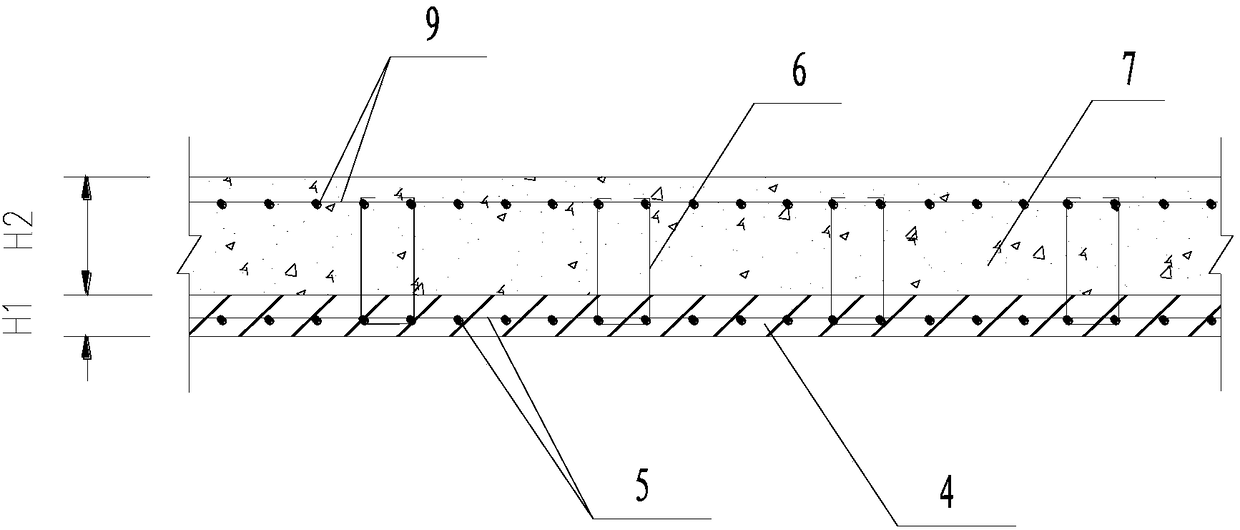

[0027] like Figure 1-6 As shown, a UHPC-ordinary concrete laminated composite bridge deck structure, including UHPC prefabricated slab 4, horizontal pre-embedded reinforcement 5, U-shaped vertical pre-embedded reinforcement 6, laminated cast-in-place concrete 7, vertical and horizontal overall reinforcement mesh 9. Concrete 10 and shear nail 3 with wet joint;

[0028] The shear stud 3 is welded on the surface of the flange plate 2 of the steel beam 1, and the UHPC prefabricated panel 4 is provided with a horizontal pre-embedded steel bar 5 and a U-shaped vertical pre-embedded bar 6, and the U-shaped vertical pre-embedded bar 6 Expose the top surface of the UHPC prefabricated panel 4, and expose the joint surface of the UHPC precast panel 4 horizontally to the pre-embedded steel bar 5. The UHPC precast panel 4 is supported on the flange plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com