Electrode system and method applicable to multi-size insulating cardboard breakdown strength tests

An electrode system and insulating cardboard technology, applied in the direction of testing dielectric strength, measuring electricity, and testing ship construction, can solve problems such as failure to meet the development requirements of high-voltage direct current transmission and low voltage level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

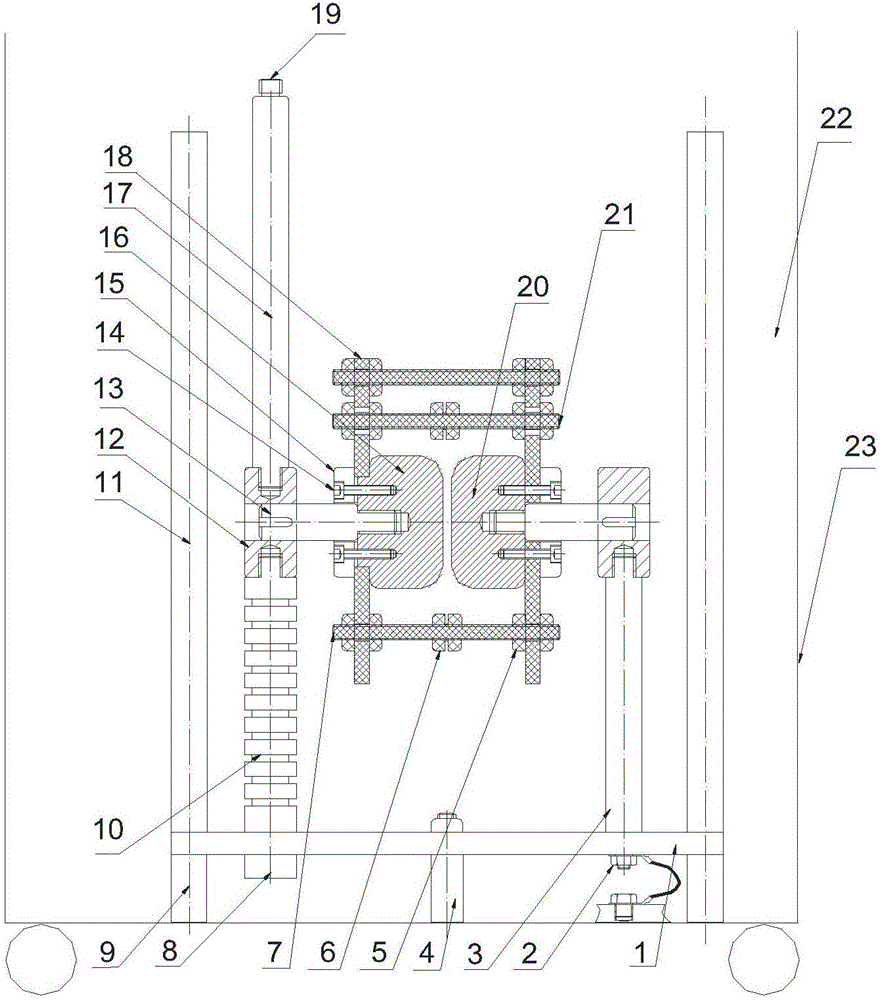

[0021] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

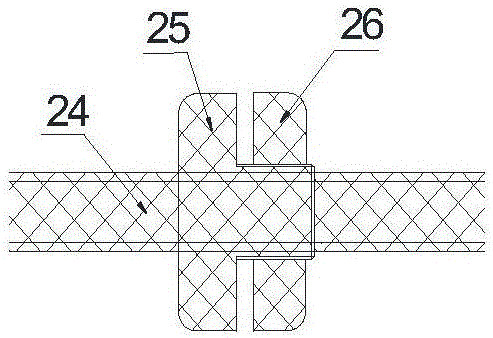

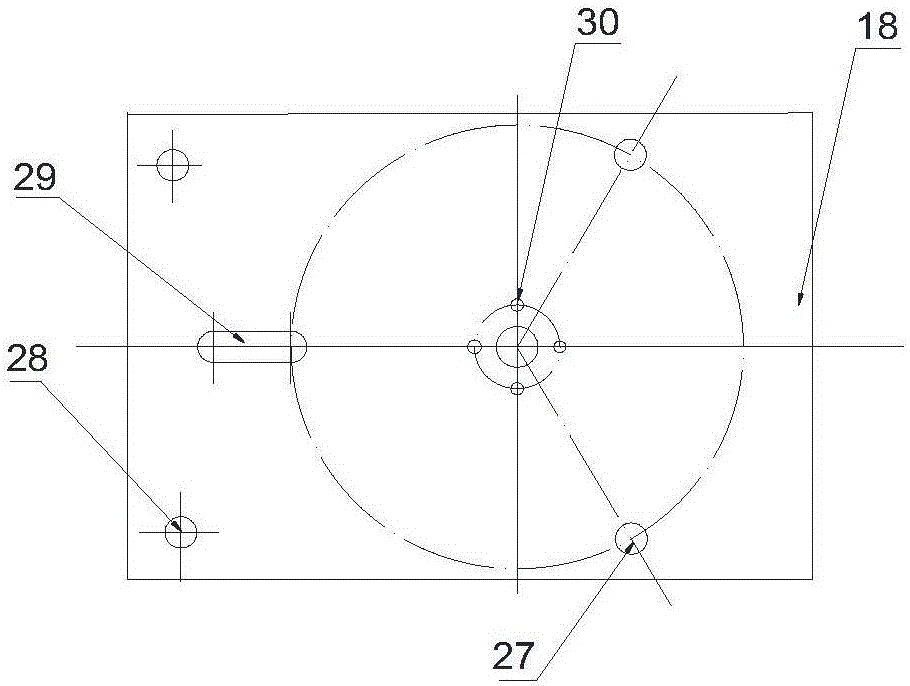

[0022] combine Figure 1 to Figure 3 As shown, the electrode system disclosed in this embodiment is applicable to the breakdown strength test of multi-size insulating cardboard, including a base plate 1, a ground lead terminal 2, a ground electrode rod 3, a fixed screw rod 7, an insulator 10 at a high voltage end, and a lifting handle 11 , high-voltage electrode 16, high-voltage end electrode rod 17, electrode mounting plate 18, high-voltage terminal 19, ground electrode 20, movable screw rod 21, wherein the ground electrode rod 3 and the high-voltage end insulator 10 are all fixed on the bottom plate 1, fixed Screw rod 7 and movable screw rod 21 are all installed on the electrode mounting plate 18; Terminal insulator 10, lifting handle 11, electrode mounting plate 18, and movable screw rod 21 are made of insulating material, and ground electrode ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com