Rotary spray head and wet etching machine

A technology of rotating spraying and spraying heads, applied in nonlinear optics, instruments, optics, etc., can solve the problems of high material cost, uneven etching, and more cost, and achieve the goal of reducing material cost and quantity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

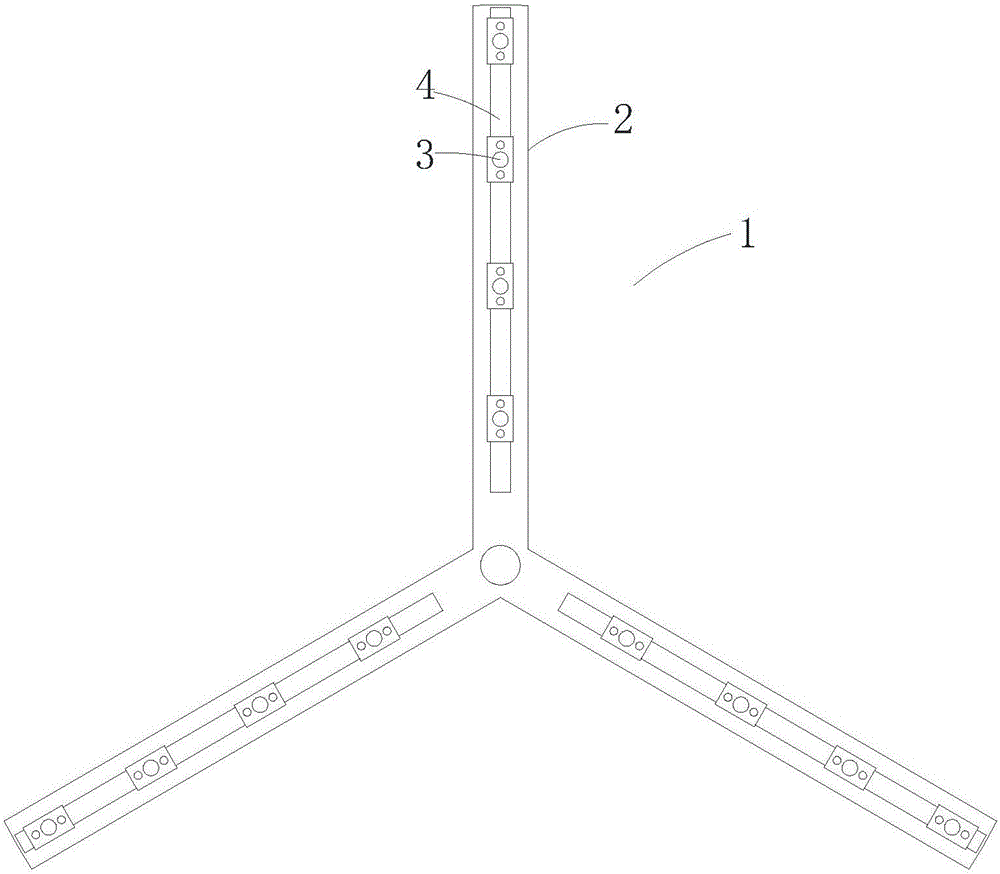

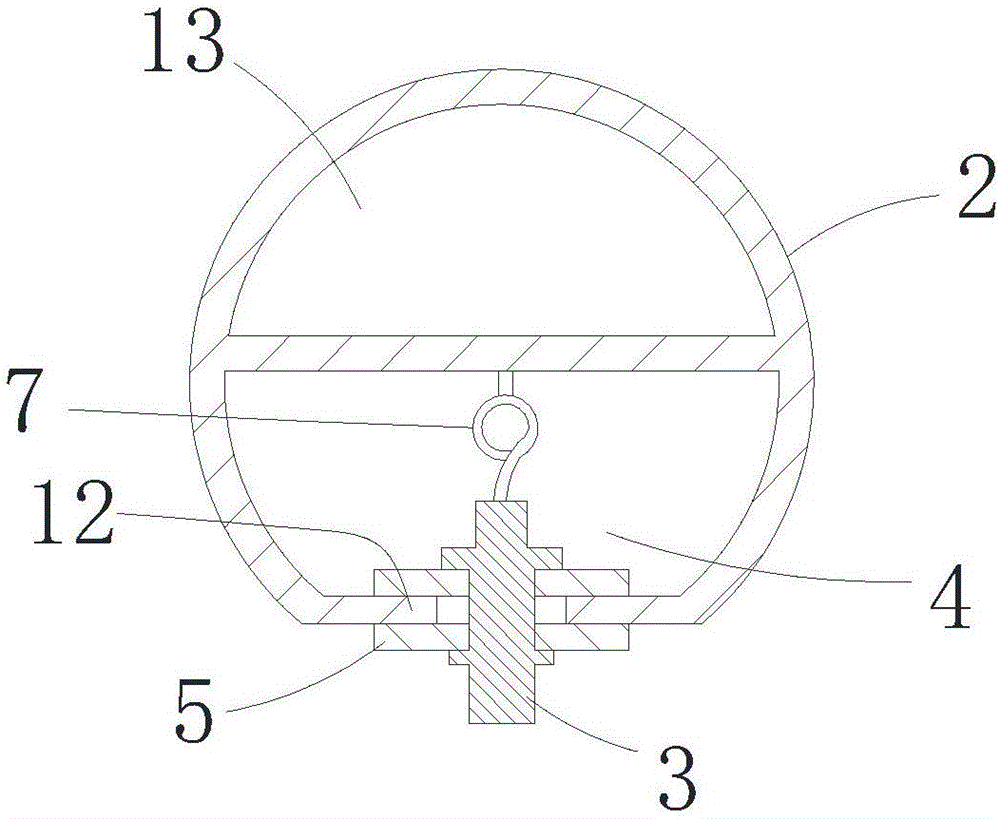

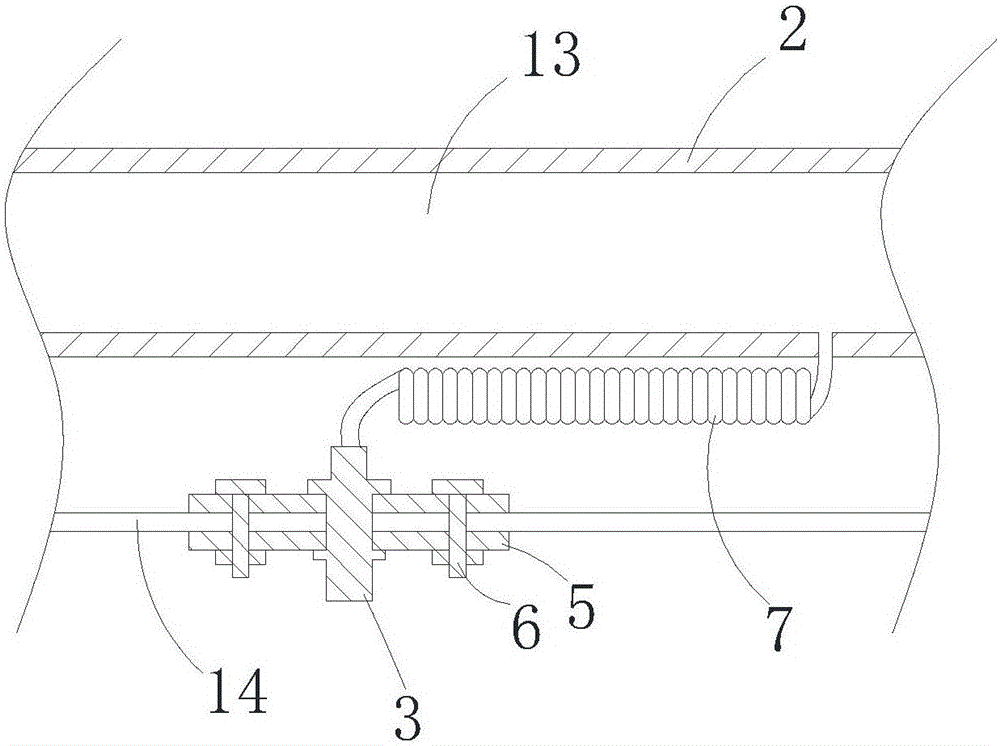

[0024] Such as figure 1 As shown, a rotary shower head of the present invention includes a shower head body 1 installed on a rotary joint, and the shower head body 1 includes at least N spray pipes 2 distributed radially along the rotary joint, wherein, N is a positive integer ≥ 3, where N=3, the opposite ends of the three spray pipes 2 are connected and communicated with each other, and the other ends of the three spray pipes 2 are closed surfaces. The liquid outlet of the rotary joint (not shown in the figure) communicates with the joints of the three spray pipes 2, and the nozzles 3 with adjustable spacing are arranged on the lower end surface of the spray pipes 2, and the nozzles 3 are arranged along the length of the spray pipe 2. Axially spaced, the distance between two adjacent nozzles 3 can be adjusted to meet the needs of substrates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com