A double-head winding machine

A winding machine and winding technology, which is applied in the direction of electrical components, inductance/transformer/magnet manufacturing, circuits, etc., can solve the problems that the winding process cannot be carried out continuously, two wire cups cannot be wound, and the progress and development of enterprises are hindered. , to achieve the effects of easy assembly, debugging and production, high winding efficiency and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

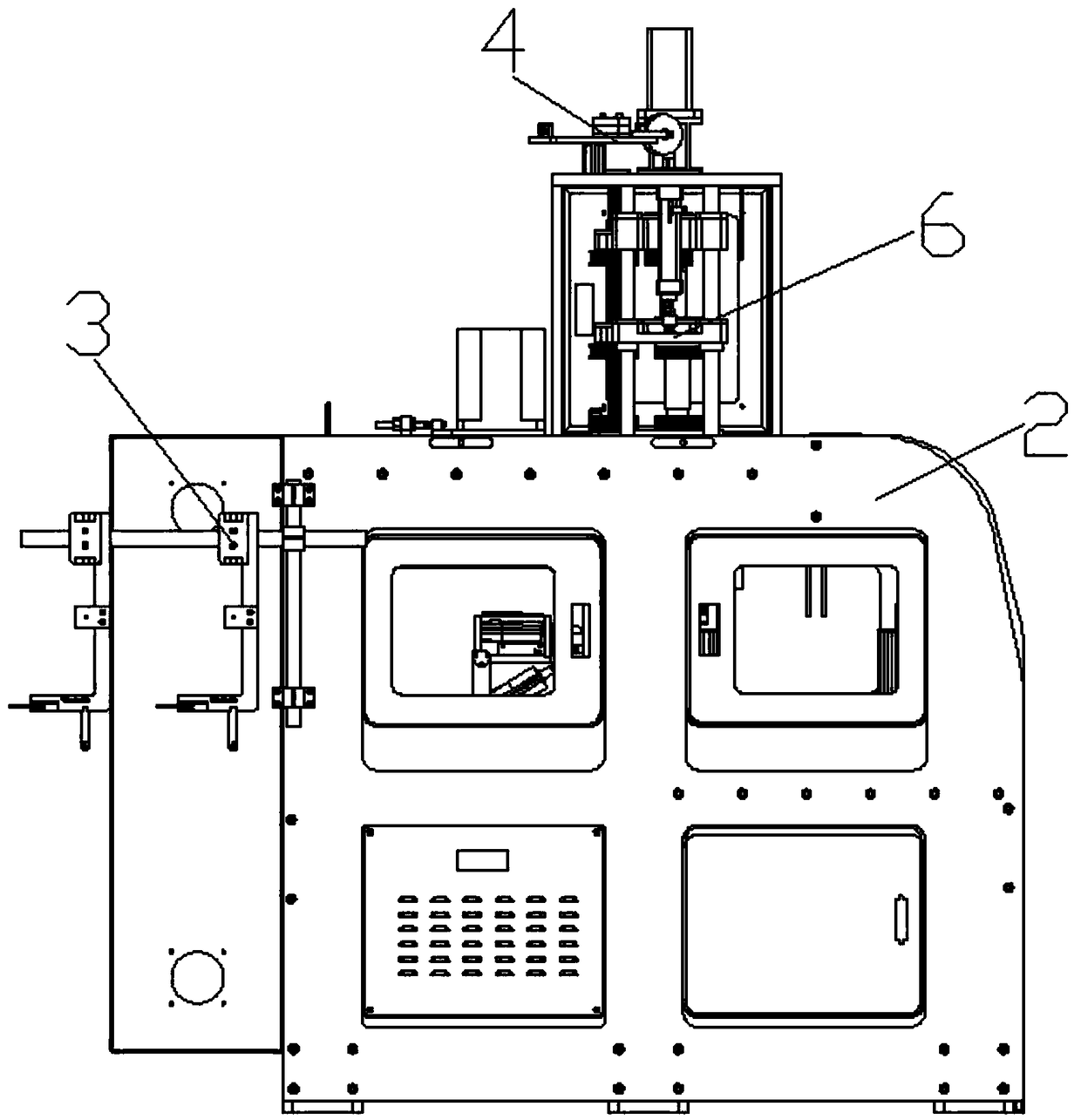

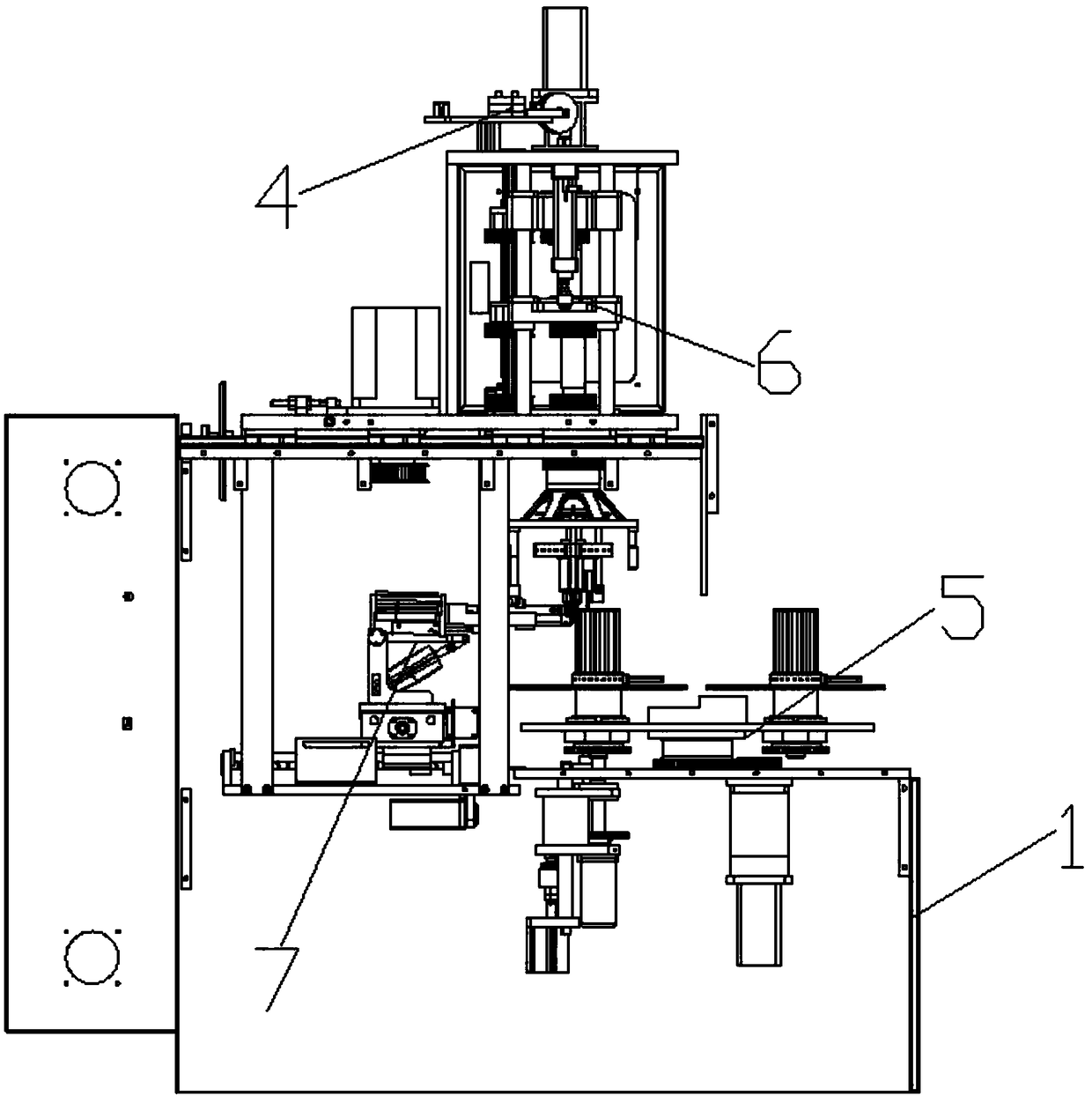

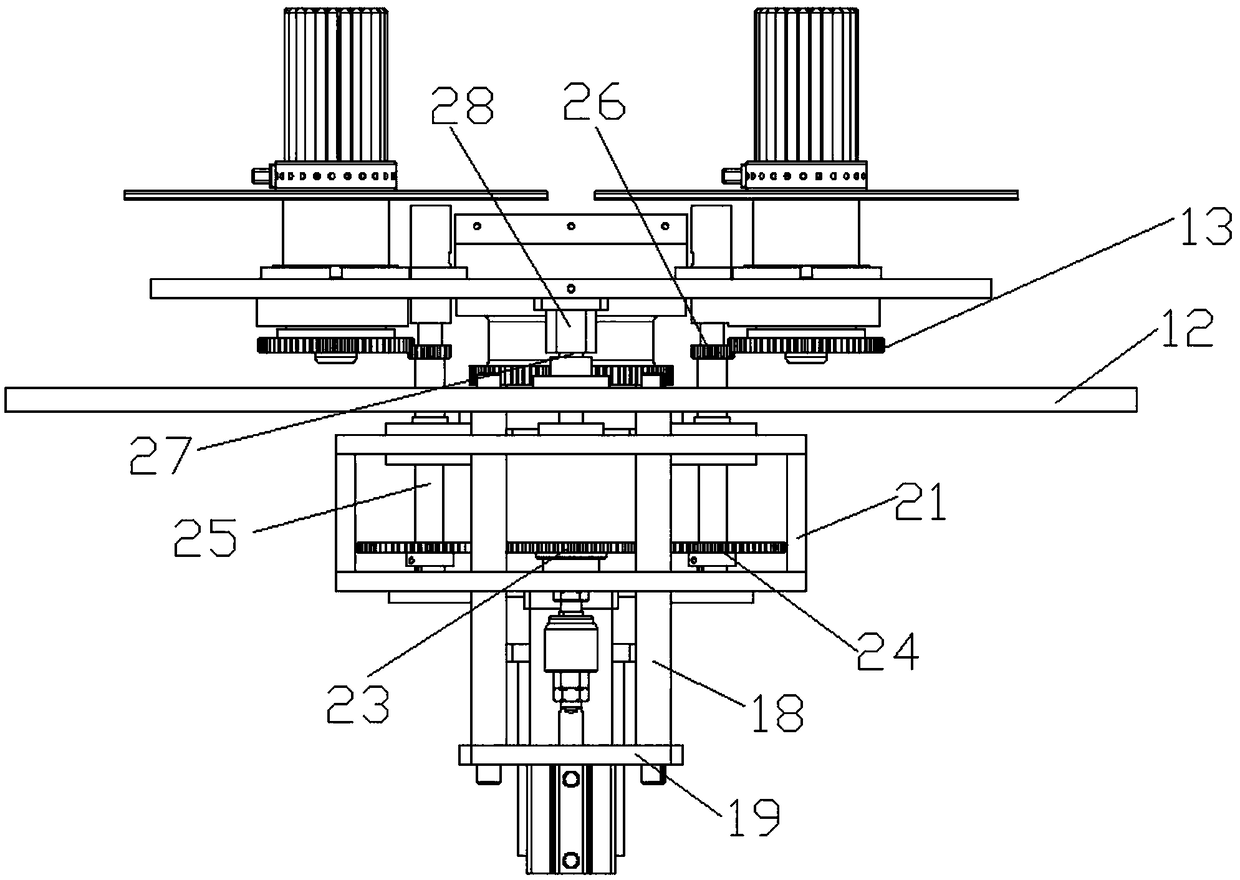

[0032] as attached Figure 1-13 The shown double-head winding machine of the present invention includes a frame 1, a machine plate 2, a wire frame 3, a wire wheel 4, a turntable transposition mechanism 5, a wire winding assembly 6 and a wire trimming assembly 7 ; The frame 1 is provided with a machine board 2 outside; the machine board 2 is provided with two opposite upper wire racks 3; the frame 1 is provided with a relatively distributed turntable transposition mechanism 5 and a thread trimming assembly 7; the top of the frame 1 is provided with a winding assembly 6 corresponding to the turntable transposition mechanism 5 and the thread trimming assembly 7; the upper end of the winding assembly 6 is provided with a wire wheel 4; the turntable switch The positioning mechanism 5 includes a turntable 11, a turntable drive mechanism, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com