Stator permanent magnet type motor

A permanent magnet motor and stator technology, applied in the magnetic circuit shape/style/structure, electric components, electrical components, etc., can solve the problems of difficult adjustment, large harmonic content of the reluctance rotor, etc., to reduce vibration noise, reduce The effect of small spikes, good harmonic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the objectives, technical solutions and effects of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. The following examples are only for explaining the present invention, and do not constitute a limitation of the present invention.

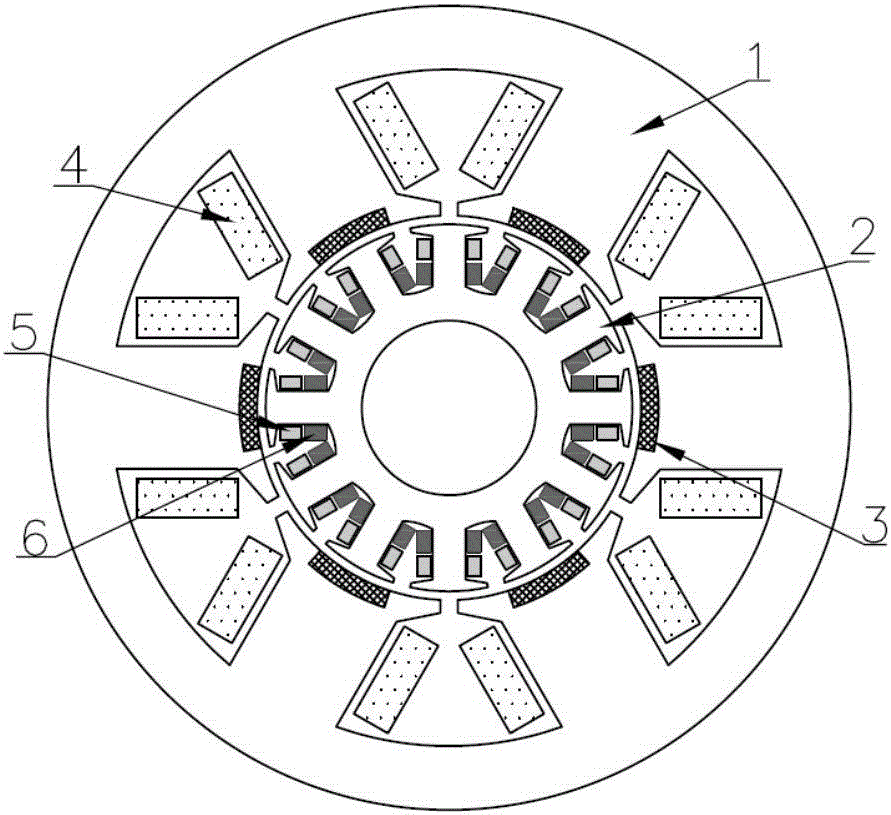

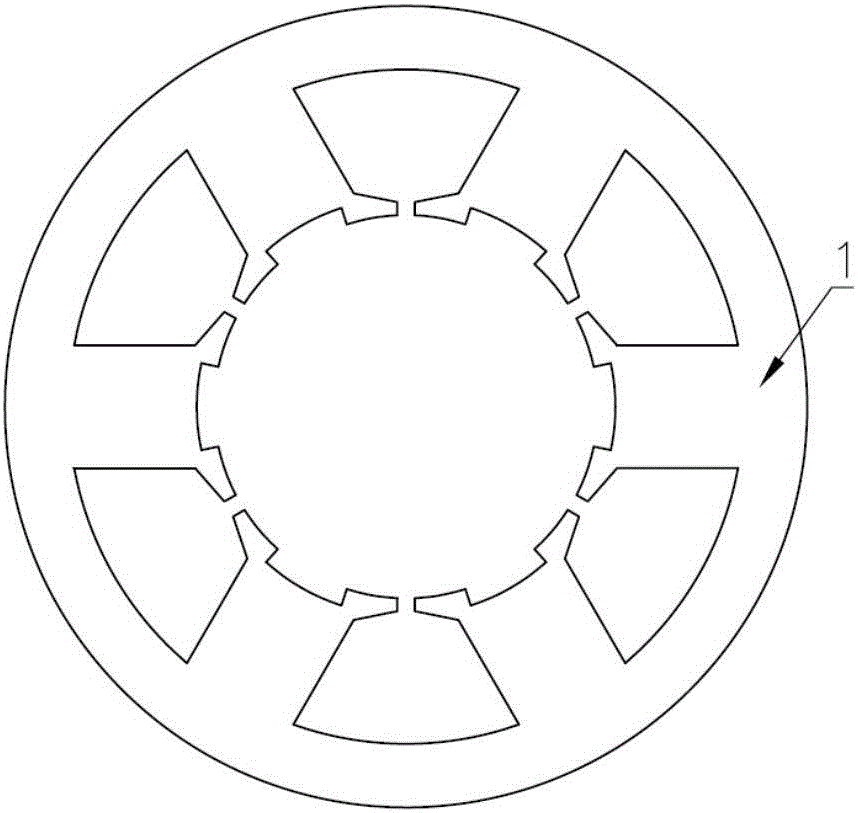

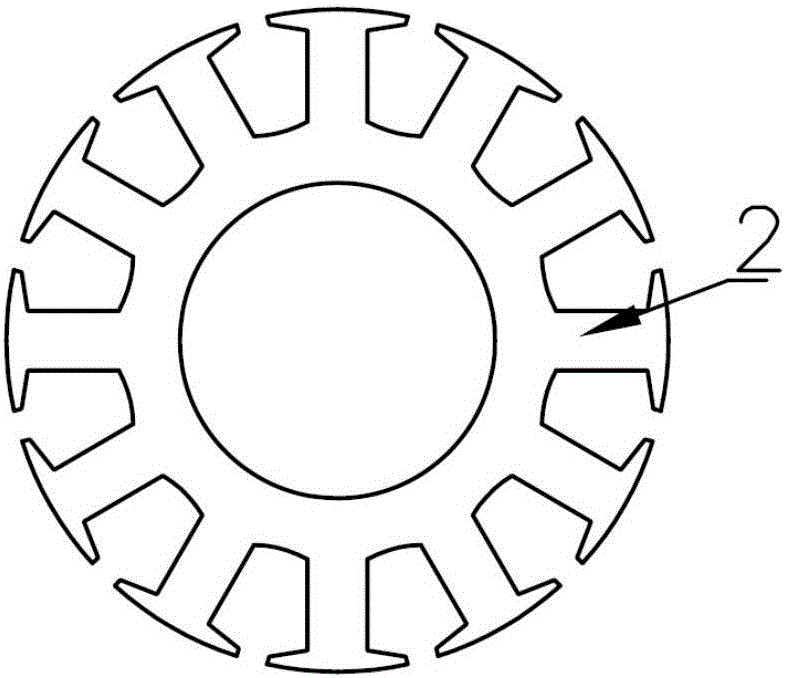

[0024] Figure 1-3 Among them, a stator permanent magnet motor, the stator 1 and the rotor 2 are magnetic cores; the permanent magnets 3 are surface-mounted embedded in the outer surface of the stator teeth, and are placed in sequence along the circumferential direction. Armature windings 4 are wound around the tooth slots of the stator core 1 . The rotor core 2 is surrounded by two sets of mutually independent windings, namely the induction winding 5 and the excitation winding 6, which rotate together with the rotor core. The number of poles of the induction winding 5 is the same as the number of poles of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com