Cover assembly with axially pretensioned wire ring for a clutch and clutch with such a cover assembly

A technology of assemblies and wire rings, applied in the direction of clutches, friction clutches, mechanically driven clutches, etc., can solve the problems of unsuitability and limitation of motor vehicles, achieve the maximum operating force that remains unchanged for a long time, improve noise characteristics, prevent noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

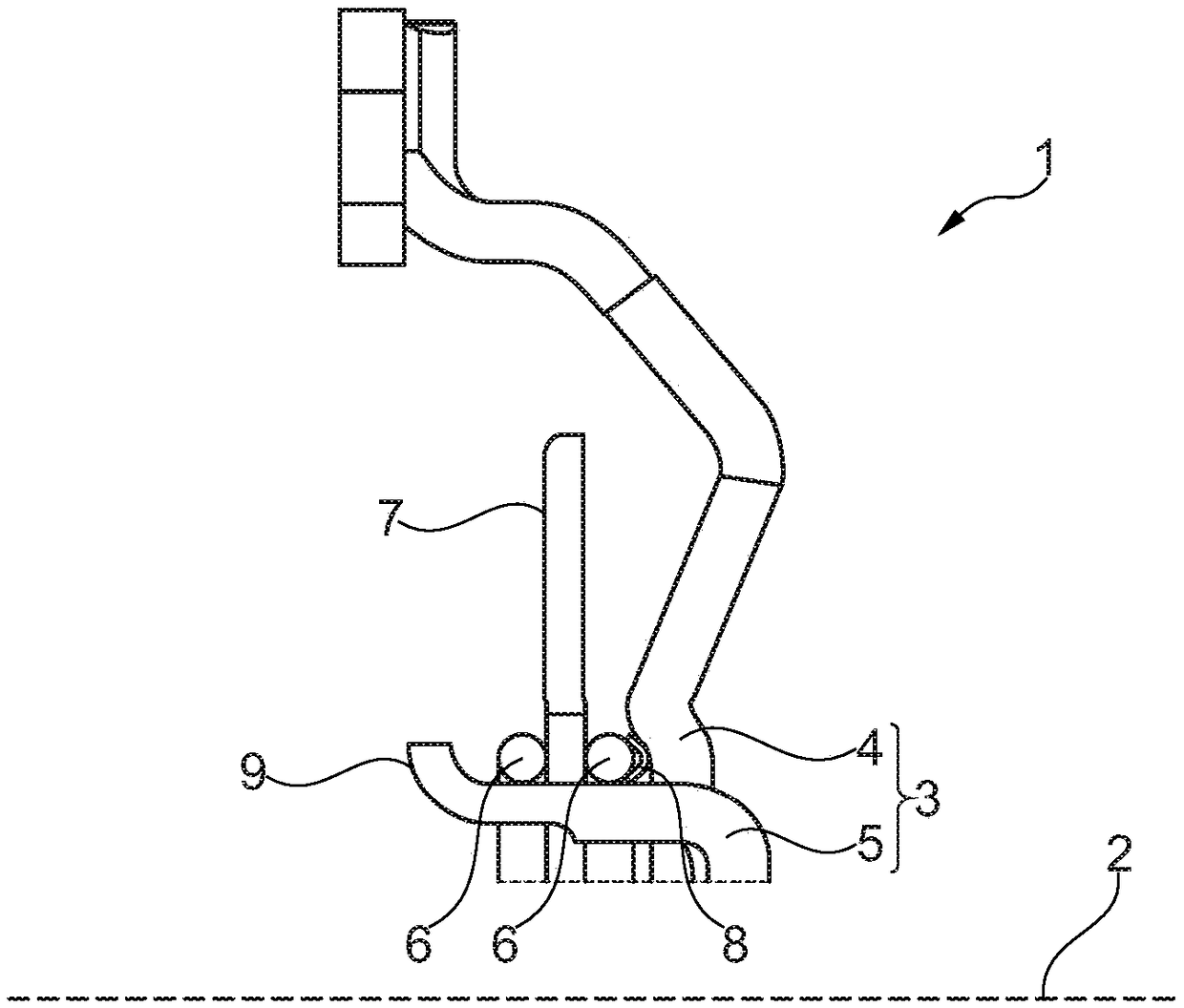

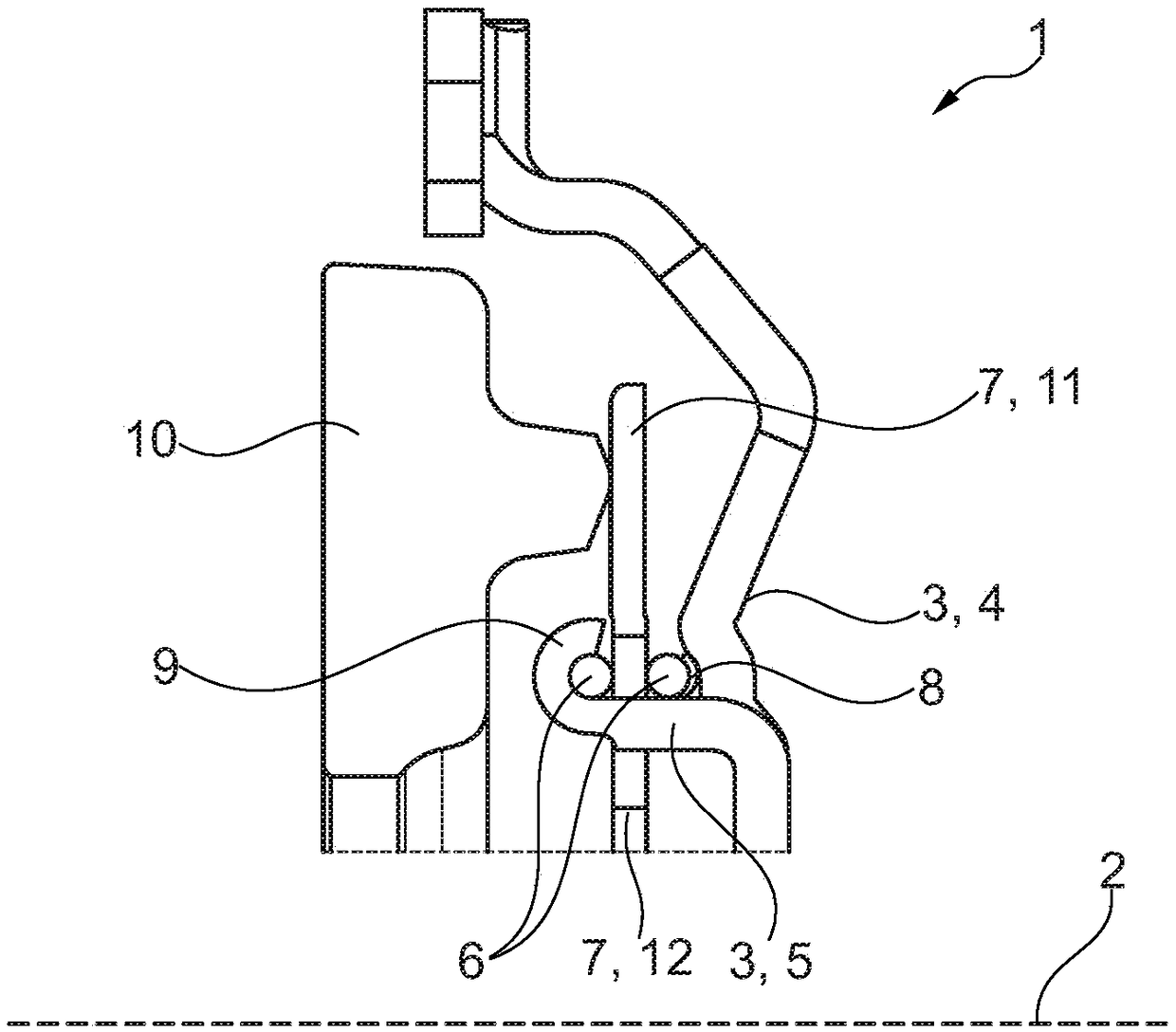

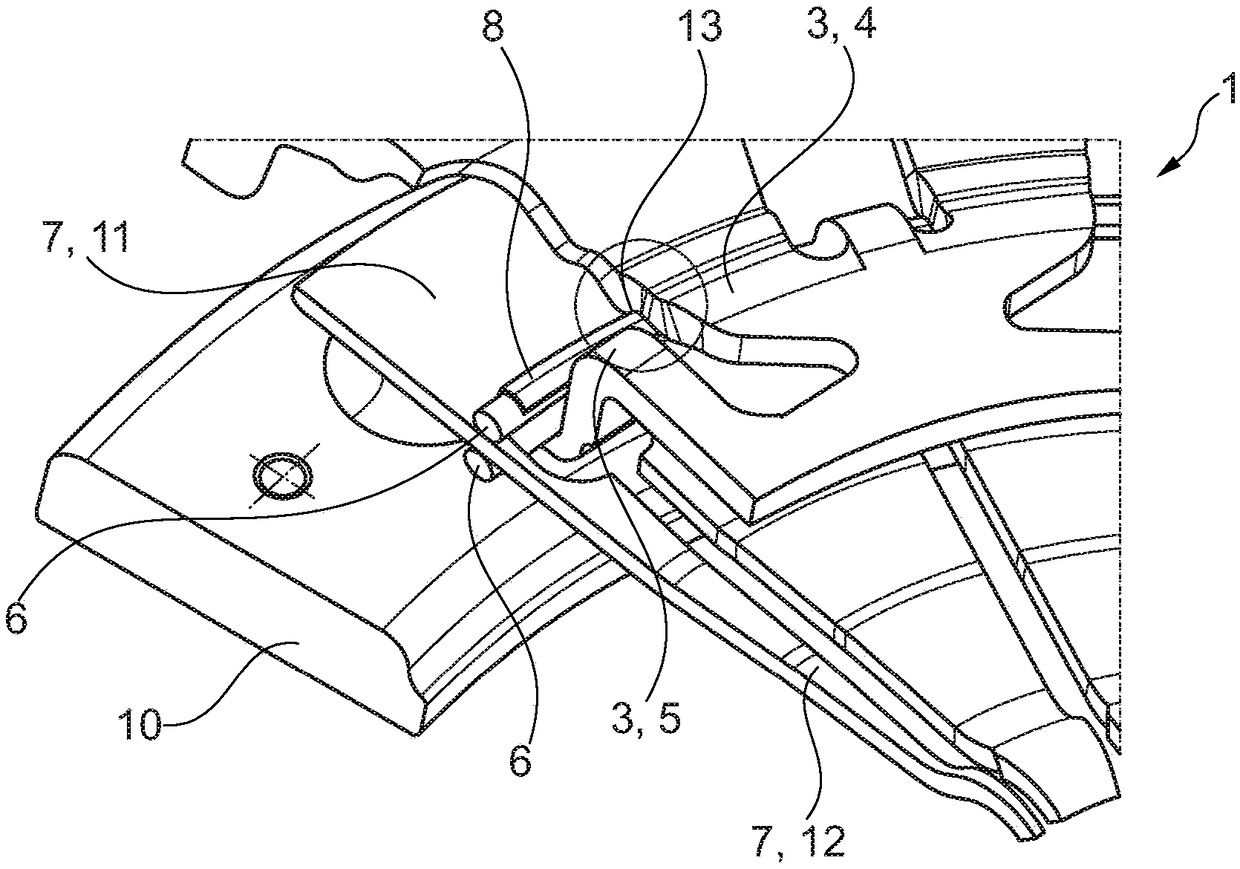

[0047] Figures 1 to 5 A cover assembly 1 according to a first embodiment of the invention is shown. exist figure 1 It can be seen in the cover assembly 1 in a sectional view parallel to the axial direction or displacement direction 2 .

[0048] figure 1 Cover 3 is shown in . The cover 3 is a molded member. In particular, the cover section 4 and the holding section 5 are shown, both of which are formed in one piece from the sheet metal part forming the cover 3 by means of sheet metal forming. Arranged radially outside the holding section 5 are two wire rings 6 , a disk spring 7 and a spring element 8 . The spring element 8 is currently arranged between the cover-side wire ring 6 and the cover section 4 , ie at figure 1 On the side of the right-hand wire loop 6 facing away from the disc spring 7 . The disc spring 7 is an actuating element within the meaning of claim 1 .

[0049] The holding section 5 extends substantially away from the cover section 4 in the axial direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com