Chemical reaction device for stirring

A chemical reaction and kettle body technology, which is applied in mixers with rotating stirring devices, chemical/physical/physical chemical fixed reactors, mixer accessories, etc., can solve the problem that the material blowing effect is not obvious and the stirring range of the agitator is small and other problems, to achieve the effect of enhancing the debonding effect and enhancing the vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

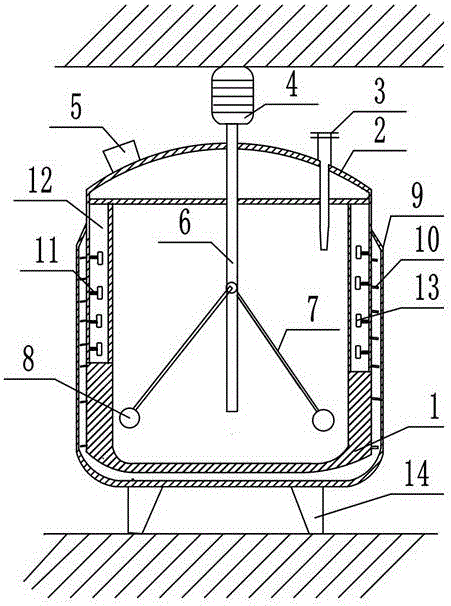

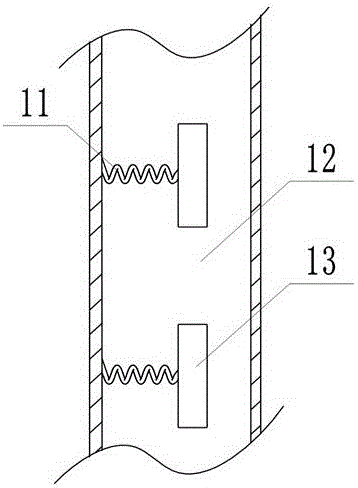

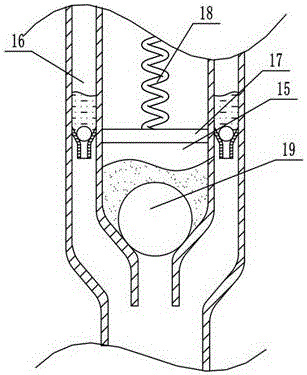

[0020] The reference signs in the drawings of the description include: kettle body 1, kettle cover 2, thermometer sleeve 3, drive 4, feed inlet 5, stirring shaft 6, stirring rod 7, stirring magnetic block 8, U-shaped jacket 9 , Lath 10, spring 11, compartment 12, bullet block 13, support 14, first cavity 15, second cavity 16, dividing plate 17, support spring 18, ball 19.

[0021] The embodiment is basically as attached figure 1 , attached figure 2 And attached image 3 Shown:

[0022] A chemical reaction device for stirring is mainly composed of a kettle body 1 , a support 14 , a stirring unit and a transmission 4 . The kettle body 1 is made of non-ferrous material. The kettle body 1 is composed of a cylinder and a lower head. The outer wall of the cylinder is coiled with slats 10. The lower head is oval. . A kettle cover 2 is installed on the upper end of the ket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com