Pencil sharpener capable of adjusting pencil tip sharpening diameter and method

An adjustable technology for pencil sharpeners, applied in sharpening devices, printing, office supplies, etc., can solve the problems of excessive cutting of pencils, the inability to adjust the cutting diameter of pencil sharpener refills, and difficulty in purchasing, so as to avoid waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

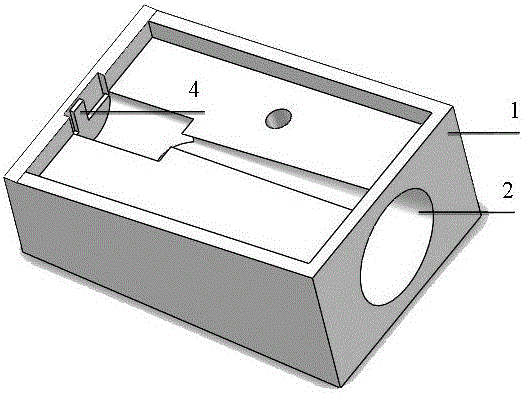

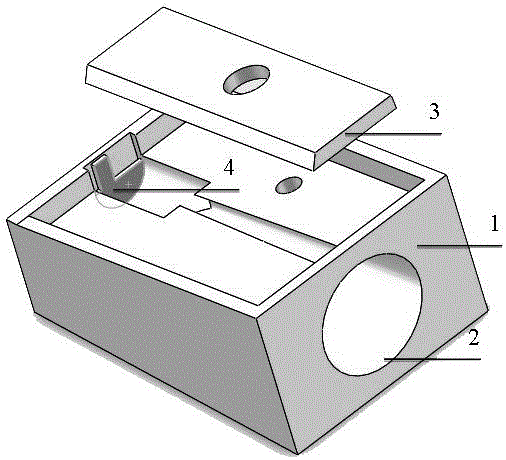

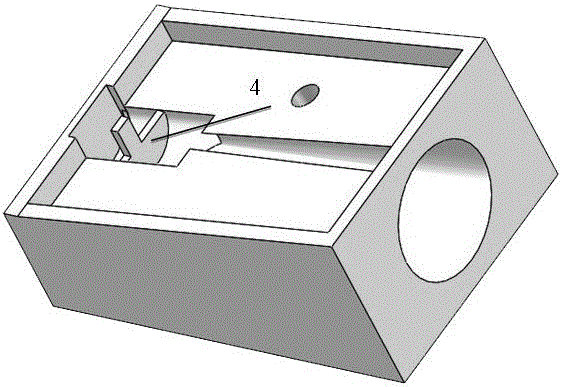

[0021] Such as figure 1 A shown method for adjusting the diameter of the cutting pencil tip is to set a movable baffle at the top end of the tapered sharpener hole of the pencil sharpener, and move along the tapered sharpener hole under the blade. Adjust the position of the baffle to change the walking distance of the pencil, and use the position of the moving baffle to adjust the diameter of the pencil sharpener for cutting the pencil tip. This method can change and adjust the cutting diameter of the pen tip and prevent excessive cutting of the thick-core pencil tip. It can not only cut pencils with ordinary refill diameters, but also achieve the effect of cutting pencils with large refill diameters without excessive cutting.

Embodiment 2

[0023] Such as figure 1 A method for adjusting the diameter of the pencil sharpener tip is shown. The initial position of the pencil sharpener baffle is at the apex of the conical sharpener hole. The distance traveled by the pencil is determined, and the cutting diameter of the pencil sharpener tip is determined. When it is necessary to change When cutting the diameter of the pencil sharpener tip, the baffle moves under the blade along the tapered sharpener hole to a specified position on the central axis of the conical sharpener hole. The cutting diameter of the pencil tip at this position is what we need to cut Pencil tip diameter. By adjusting the position of the baffle, you can get a thin pencil tip or a thicker pencil tip according to your needs. Using a pencil sharpener can meet our requirements for pencils of different thicknesses in different occasions, and bring us a sense of convenience. Come to great convenience. For example, when the examinee needs to scribble on...

Embodiment 3

[0025] Such as figure 1 A pencil sharpener that can adjust the diameter of the sharpening pencil tip as shown is mainly composed of a body, a tapered pencil sharpening hole, a blade and a screw for fixing the blade on the tapered pencil sharpening hole. The movable baffle is set, and the movable baffle is in the tapered pencil sharpener hole and moves along the tapered pencil sharpener hole. Baffle plate size is limited in the taper sharpener hole, and shape is not limited, and baffle plate can be plane, also can be curved surface, but the position of the apex end of pencil sharpener conical sharpener hole will be included in the baffle plate. The method of use is, because the movable baffle can be initially set without adjustment, and the movable baffle needs to be moved only when the cutting diameter of the pen tip needs to be changed, so the method of use is completely the same as that of an ordinary pencil sharpener, and can be used normally. When the cutting diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com