An Electric Fixture Loaded in Concealed Tanks of Sea-going Vessels

An electric and fixture technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of low steel coil loading and unloading quality, coil damage, etc., and achieve the effect of improving quality protection function, high work efficiency, and improving loading utilization space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

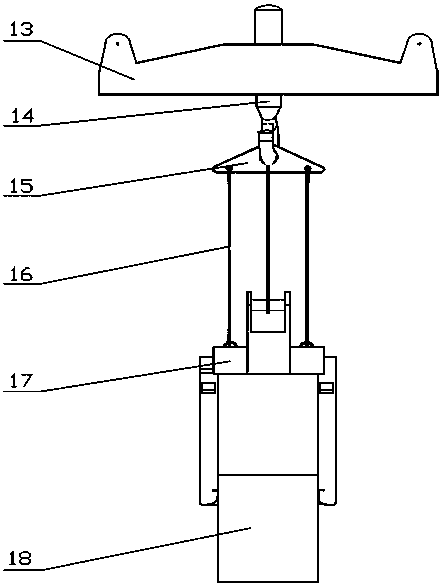

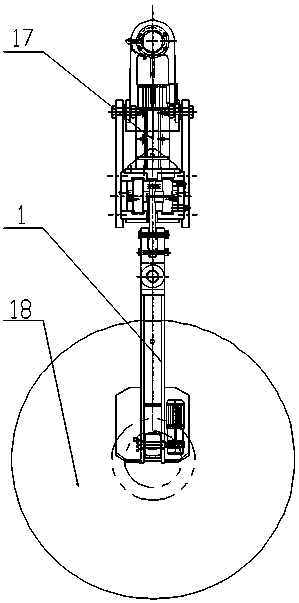

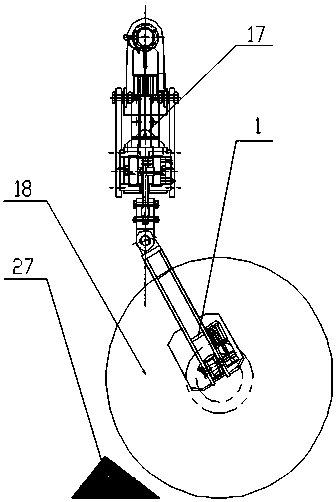

[0020] see figure 1 , figure 2 , image 3 , an electric clamp loaded in a concealed cabin of a seagoing ship, the electric clamp includes a loading and unloading bridge balance beam 13, a main hook 14, a triangular balance beam 15, a steel wire rope 16 and an electric clamp body 17, and the main hook 14 is arranged on the loading and unloading bridge balance beam 13 and the triangular balance beam 15, the steel wire rope 16 is arranged between the triangular balance beam 15 and the electric clamp body 17; the electric clamp body 17 includes the lifting lug 4 and the clamp beam, and a guide plate box is arranged above the clamp beam 2. The distribution box 5 and the transmission device 3, the swinging pincer legs 1 are arranged symmetrically on both sides of the fixture beam, and the double hook lifting lugs 6 are also arranged on the fixture beam. The technical solution ensures the personal safety of the conductor in the cabin, and even if there is a collision with other st...

Embodiment 2

[0022] see figure 1 , image 3 , as an improvement of the present invention, the electric clamp body also includes a swing leg intermediate joint 7 and a main hanging plate 8, and the swing tong leg 1 is arranged on the double hook lifting lug through the swing leg intermediate joint 7 and the main hanging plate 8 6 on. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0024] see figure 1 , image 3 , Figure 4 , Pic 4-1 , Figure 4-2 , as an improvement of the present invention, the swing pliers 1 and the swing leg intermediate joint 7 are connected through a damping adjustment component; the damping adjustment component includes a fixed adjustment disc 9, a rotating shaft 10, a damping adjustment screw 11, a damping friction Sheet 12, the damping friction sheet 12 is fixed on the side of the swing leg middle joint 7, refer to Figure 4-2 It is a schematic diagram of the structure of the swing intermediate joint. The fixed adjusting disc 9 is provided with a slot to fix the rotating shaft 10. The fixed adjusting disc 9 and the swinging pliers leg 1 are fixed together by four damping adjusting screws 11 with a diameter of 20 mm. Controllable damping can be realized by rotating 4 adjusting screws in both directions, and by adjusting the pressure between the screw and the damping friction plate. fixed. This arrangement is simple in stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com