Environment-friendly wheel-rail lubricating anti-abrasive agent

An environmentally friendly, wear-reducing agent technology, used in lubricating compositions, petroleum industry, etc., can solve problems such as unfavorable driving safety, rail oil wedge effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

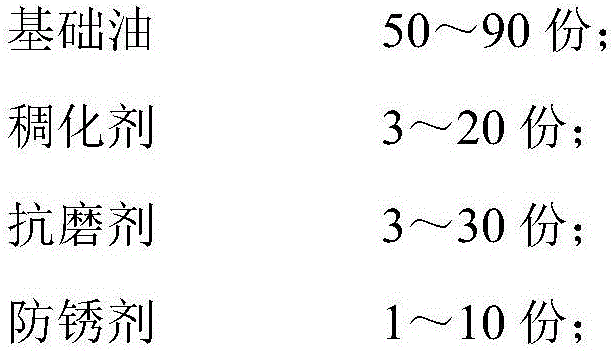

[0103] Embodiment 1: Embodiment 1 of the present invention provides an environment-friendly wheel-rail lubrication antifriction agent, in parts by weight, at least including:

[0104]

[0105]

[0106] The base oil is any one or a mixture of esters, polyalphaolefins, polyethers and vegetable oils.

Embodiment approach 2

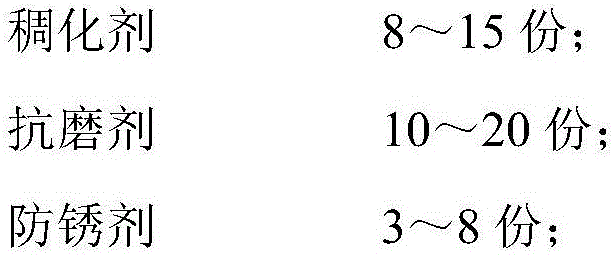

[0107] Embodiment 2: Embodiment 2 of the present invention is the same as Embodiment 1, the difference is that the environment-friendly wheel-rail lubrication and anti-friction agent at least includes:

[0108]

[0109] The base oil is any one or a mixture of esters, polyalphaolefins, polyethers and vegetable oils.

Embodiment approach 3

[0110] Embodiment 3: Embodiment 3 of the present invention is the same as Embodiment 1 and Embodiment 2, except that the kinematic viscosity of the base oil at 100°C is 5-100mm 2 / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap