Gearbox for low-speed electric vehicle

A technology for electric vehicles and gearboxes, applied in transmissions, transmission parts, gear transmissions, etc., can solve problems such as affecting the output of high-speed gears, affecting the driving texture, and the speed ratio cannot be too different, so as to improve the climbing ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

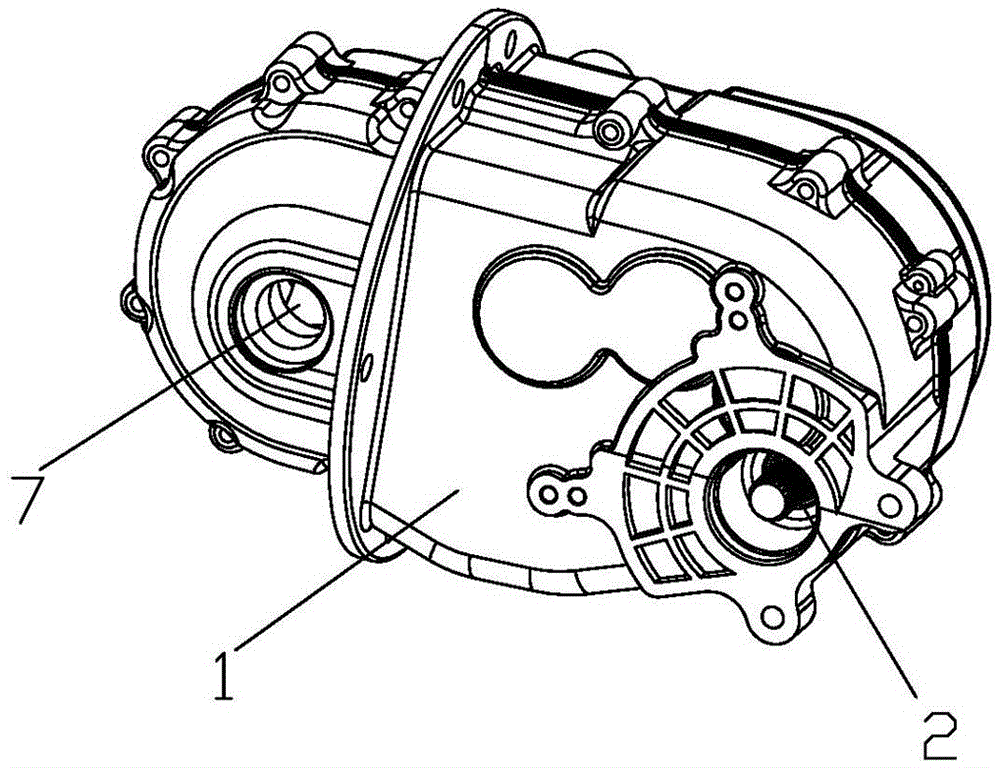

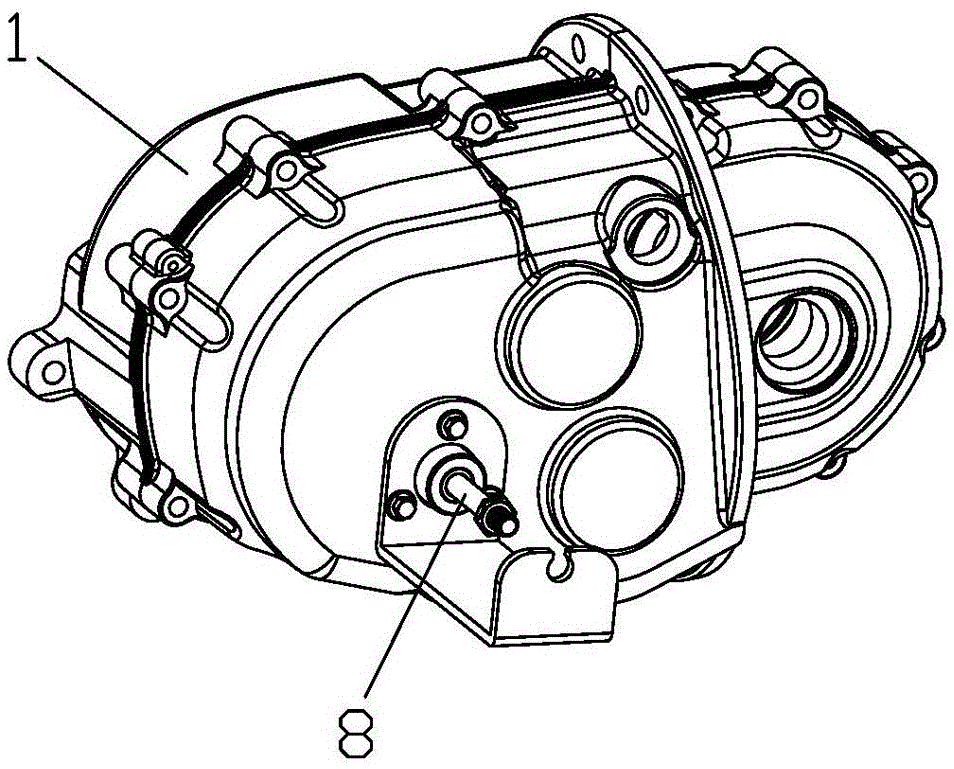

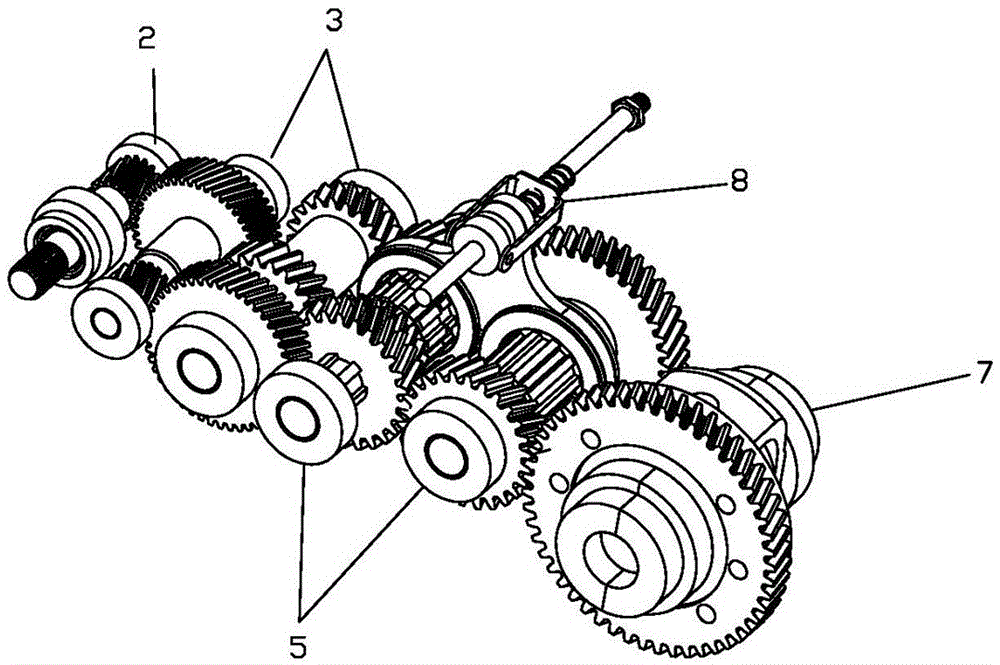

[0024] Such as Figure 1-11 As shown, a low-speed electric vehicle gearbox includes a box body 1, and a power input part 2, a deceleration part 3, a shift part 5, a power output part 7 and a shift mechanism 8 are arranged inside the box body 1, and is characterized in that : the shift part 5 includes a first gear shift pinion 51 and a second gear shift pinion 61 arranged in parallel, the first gear shift pinion 51 is sleeved with a first output tooth 52 and a first input tooth 53 , the second input teeth 54 and the short splines 55, the first output teeth 52 and the short splines 55 mesh with the first gear shift pinion 51, the first input teeth 53 and the second input teeth 54 can be shifted relative to the first gear The pinion shaft 51 rotates freely, the first input tooth 53 and the second input tooth 54 mesh with the first output tooth 31 and the second output tooth 32 of the deceleration part 3 respectively, and the short spline 55 is located on the first input tooth 53 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com