A hypersonic wind tunnel film cooling experimental system and experimental method

A film cooling, hypersonic technology, used in aerodynamic testing, testing of machine/structural components, instruments, etc., can solve the problems of rising adiabatic wall temperature and decreasing cooling efficiency of cold jet flow, reducing flow interference, Increased flow stability, clear flow structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

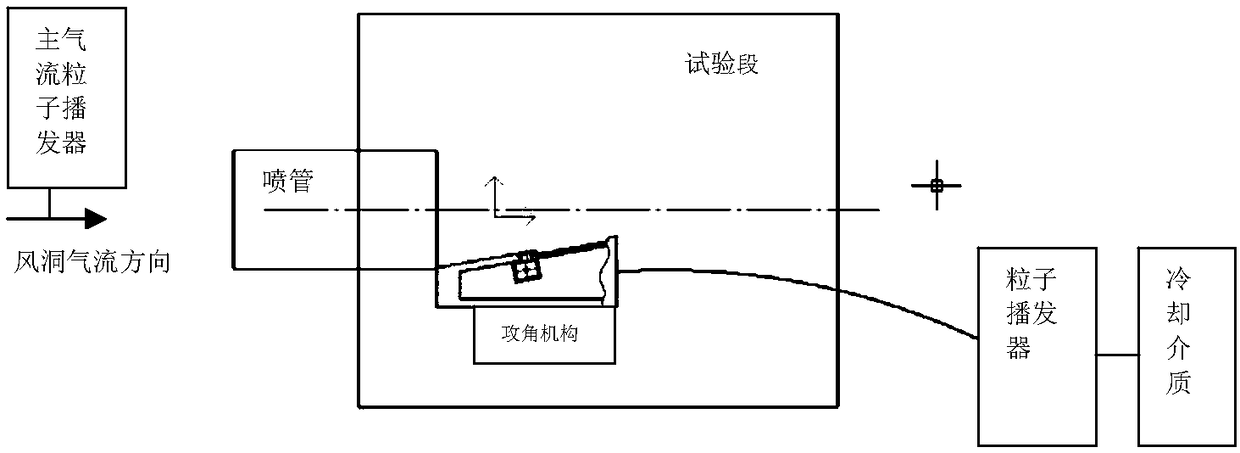

[0043] The present invention is carried out on a hypersonic wind tunnel. The overall technical solution of the invention is to use a cooling model to simulate two-dimensional cooling flow conditions, and to carry out a film cooling effect experiment under the Mach number condition of the main flight speed section. A cold shear mixed layer is formed. The pressure distribution and cooling efficiency on the window surface were measured by dynamic pressure sensitive paint, and the large eddy structure of the mixed layer was measured by particle image velocimetry.

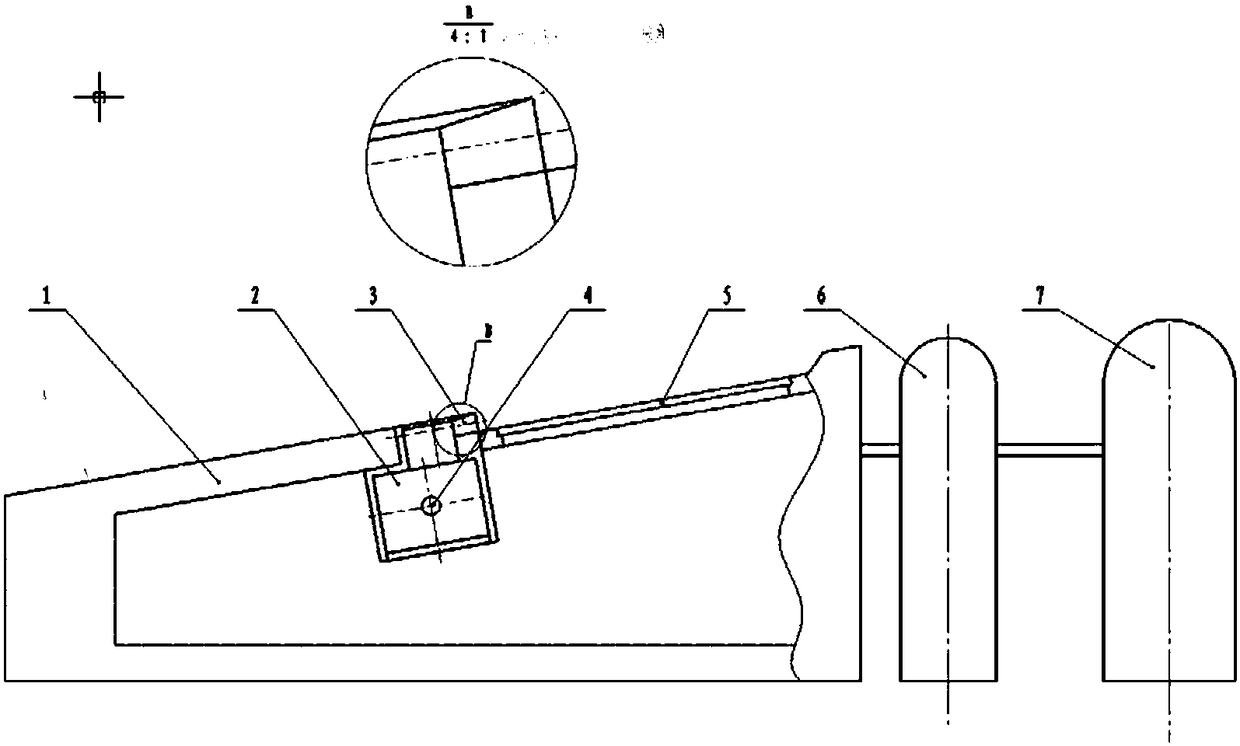

[0044] Hypersonic wind tunnel film cooling experimental system of the present invention, such as figure 2 As shown, it includes two-dimensional cooling model 1, film chamber 2, film nozzle 3, air intake channel 4, cooling window 5, particle broadcaster 6, cooling medium 7; two-dimensiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com