Method for detecting failure of cooling nozzles of finish rolling working rolls

A cooling nozzle and fault detection technology, which is applied to rolls, length measuring devices, manufacturing tools, etc., can solve the problems that it is difficult to detect the normal operation of the cooling nozzle of the finishing rolling work roll, and achieve the effect of preventing the coating from solidifying too fast and making it easy to judge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

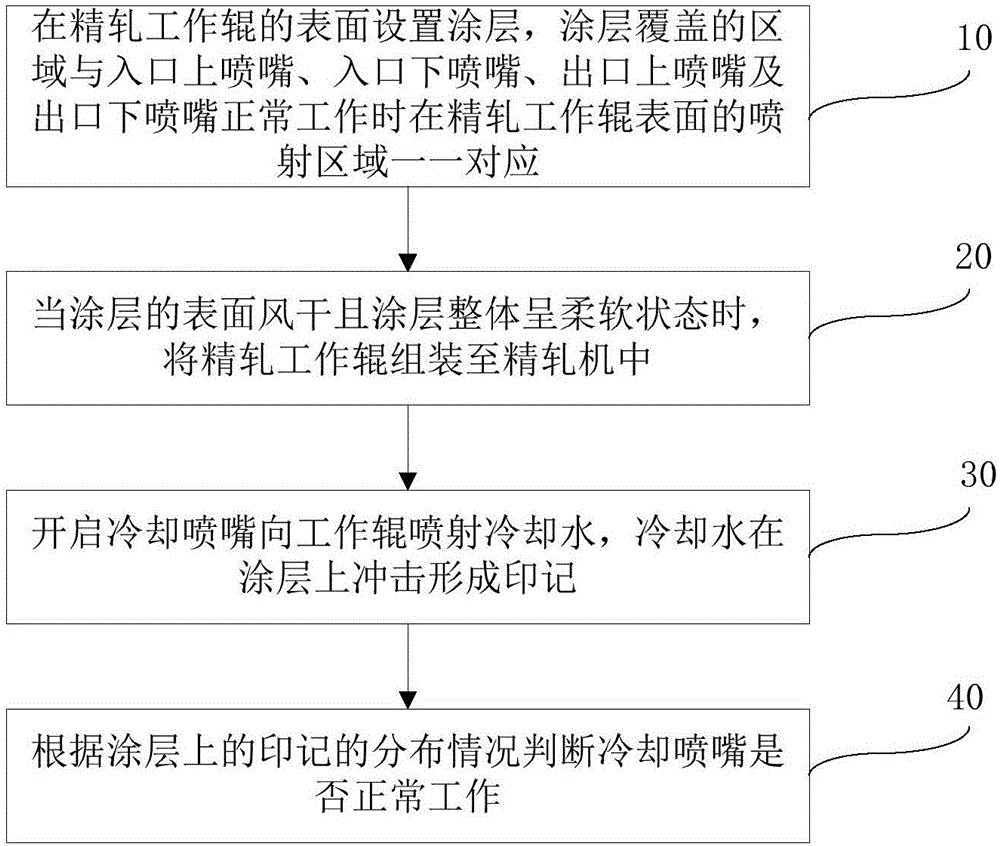

[0040] see figure 1 and figure 2 Before the finish rolling process, the method for detecting the failure of the cooling nozzle of the finish rolling work roll provided by the present invention is used to detect whether the cooling nozzle can work normally. Finishing work roll 1 is made of scrap roll, and the coating is paint layer. The surface of the finishing work roll 1 is decontaminated and dried. When the temperature of the finishing work roll 1 is cooled to 30°C, paint is sprayed on the surface of the finish work roll 1, and the thickness of the paint layer is controlled to be 0.5mm. When the upper nozzle 3 and the outlet lower nozzle 5 are in normal operation, the injection areas on the finish rolling work roll 1 are consistent. When the surface of the coating is air-dried and the coating as a whole is in a soft state, the finishing work roll 1 is assembled in the finishing mill, and the time interval from spraying paint to starting to assemble the finishing work rol...

Embodiment 2

[0042] see figure 1 and figure 2 , Before the finish rolling process, the detection method of the finish rolling cooling nozzle provided by the present invention is used to detect whether the cooling nozzle can work normally. Select the finish rolling work roll 1 that has just been dismantled from the rolling mill for use, and the coating adopts a paint layer. The surface of the finishing work roll 1 is decontaminated and dried. When the temperature of the finishing work roll 1 is cooled to 45°C, paint is sprayed on the surface of the finish work roll 1, and the thickness of the paint layer is controlled to be 1.0 mm. When the upper nozzle 3 and the outlet lower nozzle 5 are in normal operation, the injection areas on the finish rolling work roll 1 are consistent. When the surface of the coating is air-dried and the coating is in a soft state as a whole, the finish rolling work roll 1 is assembled into the rolling mill, and the time interval from spraying paint to starting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com